Rayon has become one of the most talked-about fabrics today. It feels soft, looks elegant, breathes well in the heat, and comes at a price most people can afford. Many people love wearing Rayon without knowing what makes it so special. This article will walk you through everything, from how Rayon starts as wood pulp to why your favorite summer dress drapes so beautifully.

What Exactly Is Rayon?

Rayon is a unique fabric made from natural cellulose that’s transformed through modern technology. It sits between natural and synthetic textiles, giving you softness and breathability without the high cost. Because it can mimic cotton, silk, or linen, Rayon works well for many kinds of clothing. This blend of comfort and versatility explains why it’s so widely used today. Rayon sits between natural and synthetic fabrics:

- Not fully natural like cotton

- Not fully man-made like polyester

- More like a “regenerated natural fiber”

=> Related Article: Is Polyamide Fabric Breathable Like Cotton Fabric ?

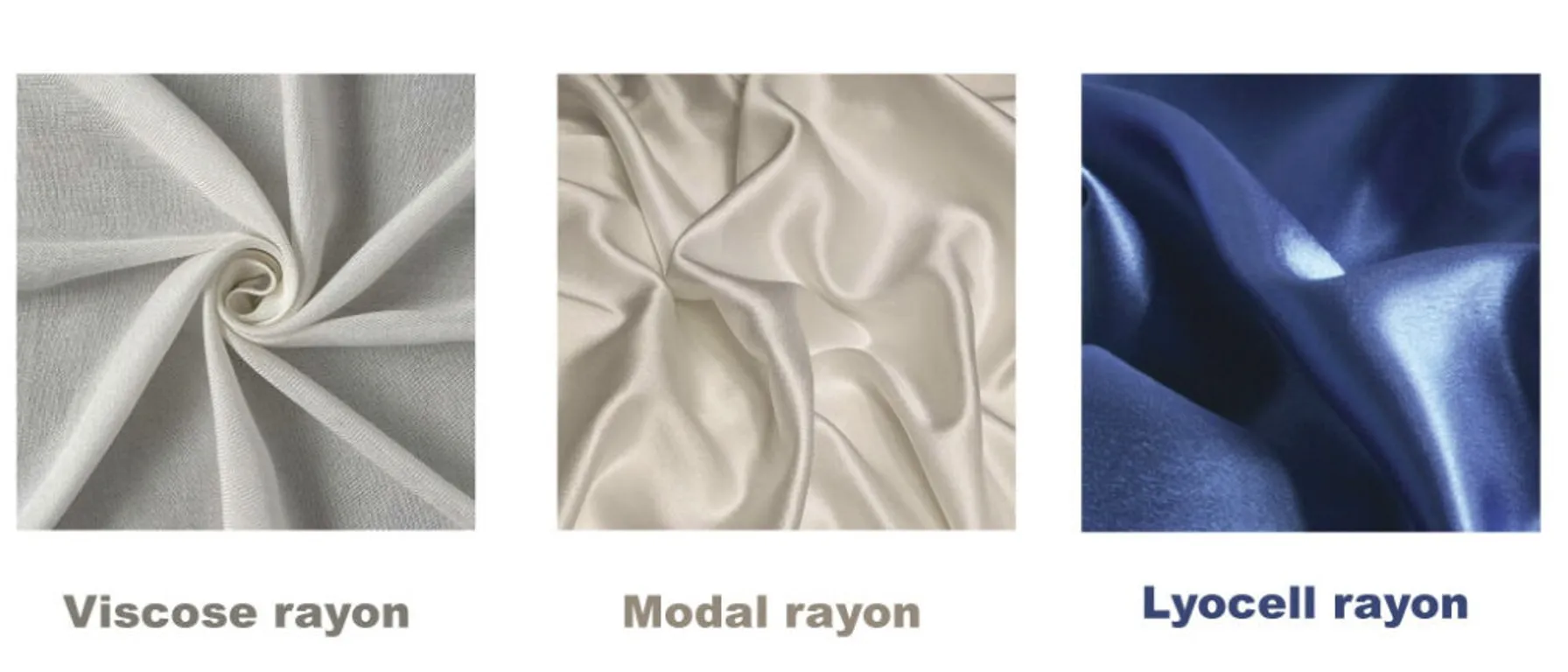

Different production methods create different types of Rayon:

- Viscose Rayon: soft and shiny.

- Modal Rayon: stronger and more stable.

- Lyocell (Tencel): eco-friendlier with closed-loop production.

Lyocell is the cleanest version because it reuses almost all chemicals during manufacturing. Rayon can mimic a lot of fabrics such as silk, cotton, linen, or even wool depending on how it’s made. This is why Rayon appears in everything from summer dresses to formal gowns.

How Rayon Is Made (From Tree → Pulp → Fiber → Fabric)

Rayon begins with wood pulp, which is turned into liquid cellulose and then spun into fine fibers. Even though it starts from nature, it requires a detailed chemical process to become a smooth fabric. This careful transformation is what gives Rayon its soft and flowing feel. Understanding how it’s made helps explain why it behaves the way it does in clothes.

- Step 1: Wood Pulp Extraction: Manufacturers use wood from pine, beech, eucalyptus, bamboo, or cotton linters. The wood is broken down into cellulose pulp.

- Step 2: Chemical Processing: The pulp is mixed with chemicals to dissolve it into a thick liquid. This is the step where Rayon becomes a “regenerated” material.

- Step 3: Extrusion Through Spinnerets: The liquid cellulose is pushed through tiny holes called spinnerets. As it exits, it forms long thin filaments the Rayon fibers.

- Step 4: Hardening and Spinning: The fibers are hardened, washed, bleached, stretched, and then spun into yarn.

- Step 5: Weaving or Knitting: Finally, the yarn becomes fabric, woven or knitted depending on the end use.

=> Related Article: Polyester Fabric: Properties, Manufacturing, and Uses

Sourcing Raw Materials

You’ll see most rayon begin with fast-growing hardwoods like eucalyptus, beech, or birch; these species give high cellulose yields (alpha‑cellulose often >85-90%). Producers increasingly source from plantations certified by FSC or PEFC to limit deforestation, while some mills blend recycled textile pulp at rates of 5-20% to cut virgin wood use and costs.

Converting Wood Pulp to Cellulose

The pulp is purified and broken down to remove lignin and hemicellulose, leaving high‑purity cellulose that you’ll chemically transform next; typical pulping yields are 40-55% wood‑to‑pulp by weight, and mills target >90% cellulose purity for spinning.

In the viscose route you’ll dissolve cellulose after alkalization and xanthation using carbon disulfide (CS2), a solvent that’s toxic and flammable, so exposure controls and recovery systems matter; the lyocell route instead dissolves cellulose in N‑methylmorpholine N‑oxide (NMMO) in a closed‑loop system with >99% solvent recovery, cutting emissions and lowering worker risk.

Fiber Spinning Techniques

You’ll encounter three main spinning methods: viscose via wet spinning, lyocell via solvent spinning, and cuprammonium for fine silk‑like yarns; spinneret hole sizes typically range 0.2-0.5 mm and fibers are produced at deniers from ~1.5 (fine) to 20-40 (apparel).

During spinning you’ll control extrusion velocity and draw ratio (often 2-4×) to align polymer chains and increase tenacity; wet spinning requires bath chemistry control to regenerate cellulose, while lyocell’s solvent spinning needs tight temperature control around 95-120°C and closed‑loop recovery to maintain that >99% solvent reuse benchmark that makes it environmentally preferred.

Finishing Processes for Rayon Fabric

After yarns are woven or knit, finishing steps like washing, bleaching, dyeing, softening and heat‑setting tailor hand, colorfastness and shrinkage; typical commercial finishes aim to cut raw fabric shrinkage (8-12%) down to under 3% with durable‑press or resin treatments.

Some anti‑wrinkle or resin finishes historically used formaldehyde‑based crosslinkers-an occupational and consumer hazard-so you’ll now often find low‑formaldehyde resins, glyoxal alternatives, or silicone and enzyme softeners; dyes require salts and pH control for even uptake, and manufacturers monitor bath chemistry to avoid excessive wastewater COD and maintain compliance with local discharge limits.

Why Rayon Feels So Good

Rayon works so well in clothing because its fibers breathe, absorb moisture, and drape naturally. It lets air move freely, keeping your body cool even on hot days. The smooth fibers feel gentle on the skin and create a soft, flowing look. These qualities make Rayon a favorite choice for comfortable and stylish outfits. Here’s what makes Rayon feel so easy and comfortable:

- Breathable and Cool: Rayon lets air pass through easily. It doesn’t trap heat, so it’s perfect for tropical climates or summer outfits.

- Moisture Absorbent: Rayon absorbs sweat better than cotton in many cases. That’s why it keeps you cool and dry.

- Soft and Smooth: The fibers are naturally smooth, giving Rayon a silk-like feel.

- Drapes Beautifully: Rayon hangs softly and flows with your body. This is why fashion designers use it for: dresses, skirts, shirts, scarves

- Takes Color Very Well: Dyes absorb into Rayon evenly, creating bright, long-lasting colors.

=> Related Article: Lyocell Fabric: How It’s Made, How It Feels, and Why It’s Everywhere

Texture and Feel

You’ll feel Rayon’s soft, almost silky surface right away; viscose offers a smooth hand while Modal and Lyocell are treated to be even softer and more resilient. Fabrics you wear daily – blouses or linings – often use 100-200 gsm rayon variants to balance softness with structure. Because the fibers are regenerated cellulose, you get a gentle, cool touch against your skin that mimics silk without the high cost, making Rayon a go-to when you want luxury-feel garments at accessible prices.

Breathability and Moisture Absorption

Rayon breathes well and shows a typical moisture regain around ~11%, compared with cotton at ~8-9% and polyester near 0.4-0.6%, so you’ll stay cooler and drier in hot weather. Its absorbency makes Rayon ideal for summer dresses and sleepwear, and you’ll notice better comfort in humid climates because the fabric lets air pass and wicks moisture away from your skin.

You should know how different types behave: viscose absorbs well but loses significant wet strength (about 40-50%)</strong), which can cause stretching or distortion when garments are washed or perspiration-soaked. By contrast, Lyocell and Modal have modified microfibril structures and chemical processes that give you improved wicking and faster moisture transport, so they dry quicker and maintain shape better. Finishes and blends also matter – a hydrophobic finish or polyester mix reduces absorbency but speeds drying, while pure rayon maximizes comfort but requires gentler laundering to avoid sagging.

Drape and Flow

Rayon drapes with a fluid, silk-like flow that flatters silhouettes; you’ll see this in challis, crepe, and dress-weight rayons used for flowing skirts and elegant blouses. Low stiffness and fine filament structure let the fabric follow body lines, so lighter weights (80-150 gsm) give dramatic movement while heavier weaves add a softer, structured fall.

In practice, fiber type, yarn twist, and weave determine how a garment hangs: challis and voile deliver maximum movement, crepe adds textured drape, and twill or sateen weaves produce more body. If you want garments that hold shape, look for blends with 2-5% elastane or choose Modal/Lyocell variants, which give better recovery and less permanent stretching than standard viscose. Tailoring choices – linings, interfacing, and hem weights – also change how rayon garments behave on your body, so designers often combine finishes and blends to get the exact drape they need.

Types of Rayon and What Makes Each One Special

Rayon comes in different versions, each designed for specific needs. Viscose, Modal, and Lyocell all share the same origin but differ in strength, softness, and eco-friendliness. This variety lets brands choose the right type for dresses, sportswear, or luxury items. Knowing these types helps you pick the best Rayon for your lifestyle.

| Viscose Rayon | Very soft, high drape; produced via the viscose process using wood pulp and chemicals like carbon disulfide; can weaken when wet and requires careful washing. |

| Modal Rayon | Made from beechwood, offers greater wet strength and dimensional stability than viscose; common for underwear and towels; often produced by branded mills with certified wood sources. |

| Lyocell Rayon | Manufactured with NMMO in a closed-loop process that recovers >99% solvent; combines high tensile strength, moisture wicking, and eco-friendly credentials (e.g., Tencel). |

| High Wet Modulus (HWM) Rayon | Also called HWM viscose; engineered for improved wet strength and reduced shrinkage compared with standard viscose; used where durability and drape are both needed. |

| Cupro (Bemberg) | Cellulose acetate-derived specialty rayon with silk-like hand, good breathability, and a smooth finish; often used in linings and luxury garments. |

=> Related Article: Polypropylene Fabric: What It Is, How It’s Made, and Key Properties

Viscose Rayon

You’ll find viscose in flowy dresses and linings because it gives you an excellent drape and silk-like hand; however, production uses chemicals such as carbon disulfide and the fiber will lose strength when wet, so you should avoid hot-machine washing and aggressive spinning to prevent distortion or shrinkage.

=> Read More: Viscose Fabric: How It’s Made, How It Feels, and Why It’s Everywhere

Modal Rayon

When you want softness plus resilience, modal delivers: it’s made from beech trees, feels silkier than standard viscose, and gives you better wet strength and reduced pilling, making it a favorite for underwear, loungewear, and high-quality towels.

=> Read More: Rayon Fabric: From Wood Pulp to Clothing

In practice, modal retains color and shape well after repeated laundering; brands like Lenzing market modal from sustainably sourced beechwood with solvent recovery and certifications (e.g., Oeko‑Tex, FSC). You’ll notice modal blends (modal-cotton or modal-elastane) perform well in garments that need stretch and recovery, and its ability to be mercerized-like finished means manufacturers can achieve a smoother, more lustrous surface without heavy synthetic additions.

Lyocell Rayon

Lyocell (often sold under the Tencel name) gives you the best environmental profile among common rayons because the solvent is recovered in a closed-loop process (>99% recovery), and the fiber provides strong, breathable fabric ideal for bedding, activewear, and denim blends. Beyond sustainability claims, lyocell stands out for its wet and dry tensile strength and excellent moisture management: manufacturers use it in performance shirts and high-end sheets because it resists pilling, dyes uniformly, and blends well with cotton and synthetics to improve hand and durability in mixed fabrics.

=> Read More: Lyocell Fabric: How It’s Made, How It Feels, and Why It’s Everywhere

Pros and Cons of Rayon

Like any fabric, Rayon has strengths and weaknesses you should know. Its softness, breathability, and elegant drape make it easy to love. But it also needs gentle care and can shrink if washed roughly. Understanding both sides helps you use Rayon confidently and keep your clothes in great shape.

Pros:

- Very soft and comfortable

- Breathable and cool

- Excellent drape

- Takes colors well

- Affordably priced

- Versatile (casual wear to luxury looks)

Cons:

- Weak when wet

- Can shrink if washed incorrectly

- Wrinkles easily

- Traditional viscose can have environmental issues

- Needs gentle care

What Rayon Is Used For

Rayon appears everywhere because it adapts well to both clothing and home décor. Its soft feel and elegant drape make it popular for dresses, blouses, and summer wear. At the same time, it’s comfortable enough for bedding and curtains. Its wide range of uses proves how flexible and practical this fabric truly is. Rayon shows up in many industries:

- Clothing: Summer dresses, Blouses, Skirts, Flowing pants, Loungewear, Formal wear, Activewear (Modal)..

- Home Textiles: Curtains, Bed sheets, Pillowcases, Tablecloths…

- Fashion Industry: Designers love, Rayon because it drapes like silk but is far cheaper.

How to Care for Rayon (To Make It Last Longer)

Caring for Rayon doesn’t have to be difficult if you follow simple steps. Gentle washing and air drying help protect the fibers and keep the fabric looking fresh. A little extra attention goes a long way in preventing shrinkage or wrinkles. With proper care, Rayon can stay soft, smooth, and beautiful for a long time. Rayon lasts a long time if cared for properly:

- Washing: Hand wash or gentle cycle, Cold water, Mild detergent

- Drying: Air dry only, Avoid strong heat, Do not wring press water out gently

- Ironing: Low heat, Iron when slightly damp

- Storage: Keep in a cool, dry place, Avoid hanging heavy Rayon garments (they can stretch)

With the right care, Rayon keeps its softness, shape, and drape for years.

Final Words / Conclusion

Rayon is more than just another fabric. It combines natural comfort with modern innovation to create clothing that feels good, looks good, and works well in everyday life. Whether you’re shopping for summer outfits, elegant dresses, or soft home linens, Rayon offers a wonderful balance of breathability, beauty, and affordability.

FAQs About Rayon Fabric From Wood Pulp to Clothing

In Short, What is rayon and how does it compare to natural and synthetic fabrics?

Rayon is a semi-synthetic textile made from natural cellulose (usually wood pulp) that is chemically processed into fibers. It combines natural-origin raw material with industrial transformation, so it can mimic cotton, silk, or linen in feel and drape while being more affordable than many pure natural or synthetic alternatives. Unlike fully synthetic fibers (polyester, nylon), rayon breathes and absorbs moisture well; unlike pure natural fibers, its properties can be engineered through production methods to enhance softness, strength, or luster.

How is rayon produced from wood pulp – what are the main steps?

Production starts with harvested wood converted into purified cellulose pulp. The pulp is dissolved or chemically converted into a viscous solution, extruded through spinnerets to form continuous filaments, then regenerated into solid fibers and spun into yarn. Common routes include the viscose method (chemical conversion and regeneration), modal (a treated-viscose variant with higher wet strength), and lyocell (a direct solvent spinning process with solvent recovery). Each step – pulping, chemical treatment, spinning, washing, and finishing – affects fabric handle and environmental footprint.

What are the different types of rayon and what distinguishes them?

Viscose is the traditional, widely used form with a soft hand and good drape but can be weaker when wet. Modal is a refined viscose with higher tensile strength, better dimensional stability, and improved softness, often used for underwear and loungewear. Lyocell (branded forms include TENCEL) uses a closed-loop solvent process that recovers and reuses most chemicals, producing a strong, absorbent, and smooth fiber favored for higher-end apparel and eco-conscious products. Choice depends on desired handle, durability, and sustainability priorities.

In Short, What are the main advantages and drawbacks of rayon fabrics?

Advantages: excellent softness and drape, high moisture absorption and breathability, ability to mimic other fabrics (silk, cotton, linen), and cost-effectiveness. Drawbacks: many rayon types weaken when wet and can stretch or shrink if washed roughly, some manufacturing routes use harsh chemicals and require careful waste management, and lightweight rayon can wrinkle easily. Proper laundering and selecting better production methods (e.g., lyocell) help mitigate many downsides.

How should I care for rayon garments to keep them looking their best?

Follow garment labels, but general care is: hand wash or use a gentle machine cycle in cold water with mild detergent; avoid bleach and fabric softeners; do not twist or wring – press water out gently; reshape while damp and lay flat or hang to air dry away from direct sun; iron on a low setting with steam if needed or use a pressing cloth. For structured or delicate pieces, professional dry cleaning is often the safest option. Avoid tumble drying to prevent shrinkage and distortion.

What are common uses of rayon in clothing and home textiles?

Rayon appears in dresses, blouses, linings, skirts, and summer wear because of its fluid drape and cooling feel. Modal and lyocell are popular for underwear, activewear blends, and premium casual wear due to softness and moisture management. Rayon is also used in home textiles such as bedding, curtains, and upholstery where a soft hand and elegant drape are desired. Its versatility lets designers target both affordable fashion and higher-end, comfortable garments.