+15 Common Fabric Defects & How to Spot Them Early, Why They Are So Dangerous

In garment manufacturing, fabric is not just a material it is the foundation of the final product. You can have a perfect pattern, skilled operators, and tight sewing control, yet one hidden fabric defect can still destroy an entire order. The real danger is timing. Fabric defects often appear after cutting or sewing, when it is already too late to fix them cheaply. At that point, the result is rework, wasted labor, delayed shipments, buyer claims, or canceled orders. For factories supplying export brands, especially U.S. and EU buyers, this can damage trust fast. That is why early fabric inspection is not optional. It is a survival system.

This article explains:

- the most common fabric defects,

- where they come from,

- how to spot them early,

- and how to build a realistic inspection process that works under production pressure.

What Are Fabric Defects?

Fabric defects are any flaws that affect the appearance, performance, or usability of fabric. They can happen at almost any stage of textile production:

- yarn spinning,

- weaving or knitting,

- dyeing and printing,

- finishing and handling.

Some defects are obvious. Others are subtle and only show up after washing, stretching, or wearing—which is exactly why buyers reject them.

Why Early Detection Matters More Than Perfection

Here is a hard truth: no fabric is 100% perfect. The goal is not zero defects. The goal is to stop critical defects from entering cutting and sewing.

A small defect rate can still destroy production if defects are:

- concentrated in visible garment areas,

- repeated across multiple rolls,

- or discovered too late.

Early detection gives you choices. Late detection gives you losses.

How to Inspect Fabric Before Cutting

Incoming Fabric Screening

Before full inspection, every lot should receive a fast but focused check:

- shade comparison against approved standard,

- width and weight check,

- surface scan for obvious defects,

- handfeel and finishing check.

If anything looks suspicious, the lot moves to detailed inspection.

The 4-Point Fabric Inspection System

The 4-point system is the most widely used fabric inspection method in apparel manufacturing.

How it works (simple version):

- defects are scored from 1 to 4 points based on size,

- total points are calculated per 100 square yards,

- common acceptance limit is 40 points per 100 square yards (unless buyer specifies otherwise).

Why it works: It standardizes judgment and makes fabric quality measurable.

Its limitation: It measures visible defects, not long-term performance like colorfastness or fabric strength. That means it should be combined with lab testing for critical styles.

The Most Common Fabric Defects in Apparel Production

1. Yarn and Structural Defects

These defects are built into the fabric structure. They cannot be washed out or pressed away.

Common examples:

- Slubs / thick yarn: uneven yarn thickness creating random bumps or lines

- Broken ends or picks: missing yarns that cause gaps or lines

- Holes or dropped stitches (knits): small holes that often grow after washing

- Barre effect (knits): horizontal streaks caused by yarn or tension variation

- Skew or bow: fabric grain twists, making garments hang crooked

Why they matter: Structural defects often appear in high-stress areas like shoulders, hips, or seams. Once the garment is worn, these flaws become more visible and lead to complaints.

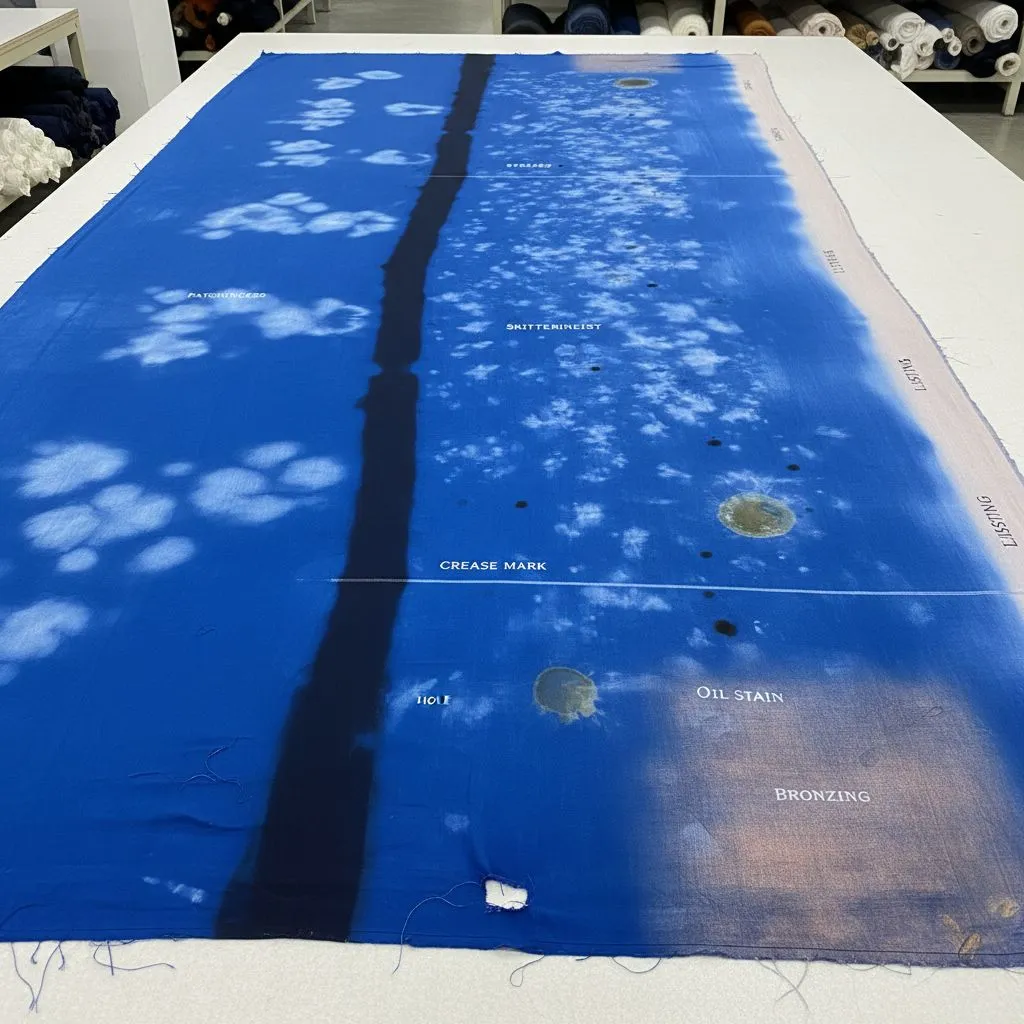

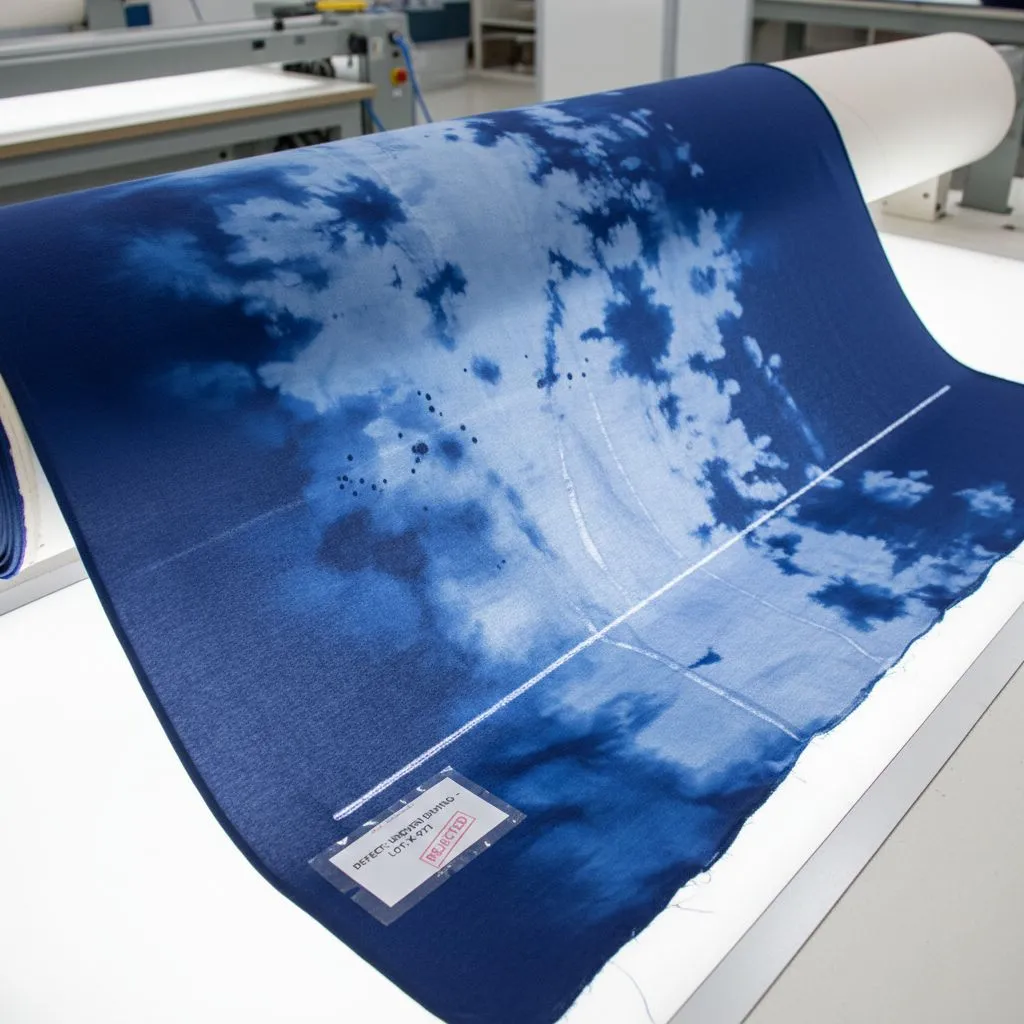

2. Dyeing and Shade Defects

Color problems are among the most expensive issues because they often affect entire rolls or dye lots.

Common examples:

- Shading or color streaks: uneven dye across width or length

- Off-shade: fabric does not match the approved lab dip or standard

- Patchy dyeing: cloudy or blotchy areas

- Poor color consistency between rolls

Why they matter: Buyers expect consistency. Even if each roll looks “acceptable,” differences between rolls can cause visible shade variation within the same garment or between cartons.

3. Printing Defects

Printed fabrics create strong visual impact, which means defects are easy to spot on finished garments.

Common examples:

- Print misregistration: colors or layers do not line up

- Blurred or broken print edges

- Repeat alignment errors

- Color mismatch to approved strike-off

Why they matter: A small print error may look minor on fabric, but once cut and sewn, it becomes impossible to hide—especially at seams or panels.

4. Stains and Contamination

These defects often come from handling, machinery, or storage rather than fabric production itself.

Common examples:

- Oil stains from machines

- Dirty selvedges

- Heat scorch marks

- Mildew smell or moisture damage

Why they matter: Many stains are permanent or reappear after washing. Even when removable, buyers often reject garments due to contamination risk.

Training Staff & Setting Up Inspection Line

Setting Up an Effective Fabric Inspection Line

You do not need expensive equipment, but you do need consistency.

Essential elements:

- strong, even lighting across fabric width,

- controlled fabric running speed,

- meter counter,

- chalk or stickers to mark defects,

- defect mapping sheet,

- clear accept / repair / reject rules.

Big mistake to avoid: Inspecting fabric too fast. Speed hides defects.

Training Staff to Spot Fabric Defects Early

Even the best inspection table fails if inspectors are not trained.

What good training includes:

- real defective fabric swatches,

- defect photos grouped by category,

- clear decision rules: reject, repair, accept,

- regular refresher sessions.

A practical approach is to teach inspectors to ask one question:

“Will this defect be visible or cause failure after the garment is worn or washed?” => If the answer is yes, stop the fabric.

Using Visual Aids on the Factory Floor

Visual tools dramatically improve consistency:

- defect photo charts near inspection tables,

- laminated pocket guides,

- defect samples mounted on boards.

These tools reduce personal interpretation and speed up decision-making during busy production periods.

Working With Fabric Mills to Reduce Defects at the Source

Inspection alone does not solve recurring problems. Supplier management does.

Track supplier performance

Maintain a simple scorecard:

- rolls received,

- rolls rejected,

- major defect types,

- defect rate by lot.

Share this data openly with suppliers.

Push preventive actions

Ask mills to:

- send swatches from each dye lot,

- share pre-shipment inspection reports,

- improve inline quality control,

- use clear roll identification and tracking.

When suppliers see consistent feedback, quality improves faster.

Conclusion / Final Words

Fabric defects are silent profit killers. They hide early, explode late, and damage trust quickly. But when factories understand common defect types, inspect fabric before cutting, train inspectors properly, and work closely with mills, those risks drop sharply. Early fabric inspection is not about slowing production. It is about protecting everything that comes after labor, delivery schedules, margins, and brand reputation.

Our Contact Information – MEKONG GARMENT FACTORY

- Vietnam Phone: +84 947 729 829

- WeChat: +84 947 729 829

- WhatsApp: +84 947 729 829

- Email: hanh@kimmy.vn