Many apparel brands assume they must sacrifice speed to protect quality, or sacrifice quality to meet shipping deadlines. This belief is understandable, because poor quality control often shows up as delays, rework, and last-minute chaos. But the real issue is not quality itself. The issue is how and when quality is managed.

After thousands of production runs, one lesson stands out: quality control causes delays only when it is treated as a final obstacle instead of a built-in system. When quality is integrated into production, it actually protects timelines rather than threatening them. This article explains the systems, strategies, and conditions required to maintain strict quality standards while keeping shipments on schedule.

Integrated Quality Systems: Prevent Problems Before They Become Delays

Integrated quality systems distribute inspection throughout the production process instead of concentrating it at the end. This approach changes quality control from a reactive activity into a preventive one. Rather than discovering large-scale defects during final inspection, issues are identified when they are still small and easy to correct. When quality checks are embedded into each production stage, factories avoid the time pressure and risk associated with late discoveries. Problems are solved incrementally instead of accumulating into shipment-threatening surprises. However, these systems only work when inspectors have real authority and production teams respect quality decisions.

In-Process Inspection: Catch Errors at the Source

In-process inspection focuses on detecting defects at the moment they appear. This prevents mistakes from flowing into the next operation and multiplying across dozens or hundreds of units. The earlier a defect is found, the less time and cost it takes to correct. By checking quality after cutting, during sewing, and before finishing, factories reduce rework dramatically. Corrections are handled within hours instead of days. In-process inspection shortens total production time not by eliminating inspection, but by eliminating mass correction later.

Key checkpoints typically include:

- After fabric cutting

- During critical sewing operations

- Before finishing and packing

Benefits of in-process inspection:

- Defects are corrected within hours, not days

- Rework volume drops sharply

- Final inspection rejection rates decrease

The result is not more inspection time, but less total correction time.

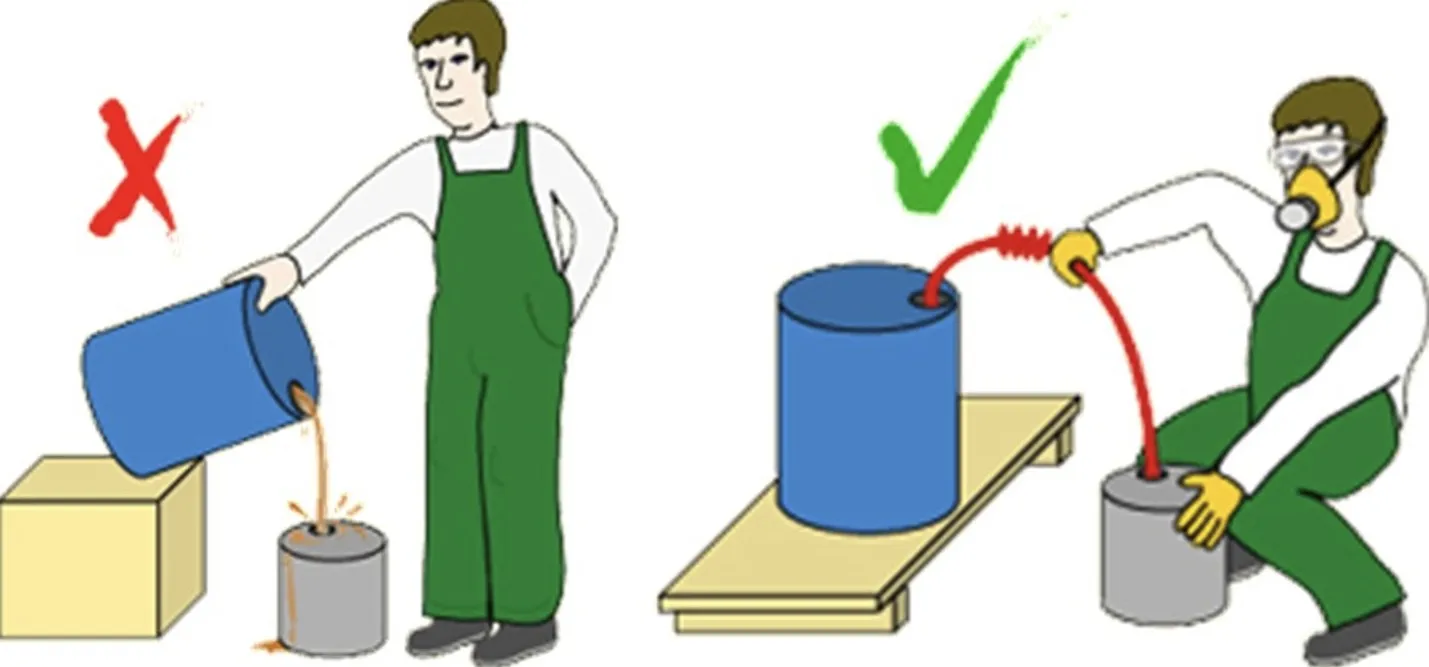

Stop-Line Authority: The Hidden Requirement

In-process inspection fails when inspectors can only report issues but cannot stop production. Without stop-line authority, defects continue downstream even after being identified. This turns inspection into documentation rather than control. Effective factories empower quality teams to pause production immediately when critical issues appear. This authority protects both quality and timelines by preventing the spread of defects. Without it, even the best inspection system becomes ineffective.

Effective factories ensure:

- QC staff can stop the line immediately for critical issues

- Supervisors must respond, not argue

- Production resumes only after correction

Without stop-line authority:

- Defects multiply

- Rework explodes near shipment dates

- Inspection becomes meaningless

Standardized Quality Procedures: Speed Through Consistency

Standardized procedures create a shared understanding of what “acceptable quality” actually means. Without clear standards, inspectors debate, supervisors hesitate, and decisions slow down. Consistency removes confusion and speeds up judgment. However, standardization does not mean documenting everything. Too many checkpoints can create bureaucracy and box-ticking behavior. The goal is to standardize what matters most, not every possible detail.

Defined Checkpoints and Acceptance Criteria

Clear checkpoints ensure inspections happen at the right moments, not randomly or too late. Each checkpoint focuses on specific, high-risk quality elements. Inspectors know exactly what to measure and what tolerance applies. Defined acceptance criteria eliminate negotiation during inspection. Pass or fail decisions become faster because expectations were agreed upon in advance. This reduces re-inspection and approval delays.

Effective procedures define:

- What must be checked

- When it must be checked

- What is acceptable or unacceptable

This eliminates:

- Inspector interpretation gaps

- Supervisor override confusion

- Repeated buyer clarifications

Unified Tools and Measurement Methods

Using different tools or methods creates inconsistent results. When measurements vary by inspector, confidence drops and inspections slow down. Standard tools ensure reliable data and faster decisions. Unified measurement methods also reduce disputes with buyers. When everyone uses the same reference, approvals move faster and fewer clarifications are needed.

Standardized systems require:

- Same measuring tools for all inspectors

- Same tolerance references

- Same reporting format

Consistency builds speed because trust replaces debate.

Proactive Risk Management: Eliminate Repeat Problems

Most quality issues are predictable. The same fabrics fail in similar ways, and the same styles create recurring defects. Proactive risk management uses this history to prevent problems before production begins. Instead of reacting to defects after they appear, factories analyze past data to identify high-risk areas. This shifts quality control from defect detection to defect prevention.

Using Historical Data to Predict Risk

Historical defect data reveals patterns that are easy to overlook in daily operations. Certain operations consistently produce errors. Certain materials consistently create problems. By identifying these patterns early, factories can adjust processes, assign skilled operators, or add targeted checks. Preventing known risks is far faster than fixing them later.

Factories track recurring issues such as:

- High-defect styles

- Fabric shrinkage or color instability

- Complex operations with frequent errors

This data allows teams to:

- Add early checkpoints

- Assign skilled operators

- Adjust processes before bulk starts

Monitoring Trends During Production

Risk management does not stop at pre-production. Ongoing trend monitoring detects early warning signs during bulk production. Small deviations are addressed before they become widespread. This approach reduces surprise failures during final inspection. Production remains stable, and timelines stay intact.

Teams monitor:

- Rising defect rates

- Measurement drift

- Operator-specific errors

Small signals are addressed early, preventing large-scale failures.

Supplier Qualification: Protect Quality Before Production Starts

Material quality has a direct impact on delivery schedules. When fabric or trims fail inspection, replacement often takes weeks, not days. No amount of production efficiency can recover that lost time. Strong supplier qualification reduces incoming defects and shortens inspection time. However, this strategy only works when factories are allowed to influence sourcing decisions rather than accepting price-only choices.

Approved Vendor Lists and Performance Tracking

Approved vendor lists are built on performance, not promises. Suppliers are evaluated based on consistency, defect rates, and responsiveness. Poor performers are removed over time. Performance tracking ensures material quality improves instead of fluctuating. Reliable suppliers protect both quality and schedule stability.

Effective supplier systems include:

- Approved vendor lists based on performance

- Ongoing defect and delivery tracking

- Removal of inconsistent suppliers

This creates:

- Stable incoming quality

- Faster incoming inspections

- Fewer production stoppages

Incoming Inspection as Risk Control, Not Delay

Incoming inspection should confirm consistency, not discover surprises. When suppliers are qualified, inspections become faster and more predictable. This reduces rejection rates and avoids production stoppages. Incoming inspection works best as a verification step, not a battlefield. When suppliers are qualified:

- Inspection time drops

- Rejection rates fall

- Production flows without interruption

Incoming inspection becomes a safeguard, not a bottleneck.

Training and Workforce Discipline: Reduce Defects at the Source

Inspection does not create quality. People do. Well-trained operators make fewer mistakes, which reduces the need for heavy inspection later. Training focused on real defect patterns delivers measurable improvements in first-pass quality.

Targeted Operator Training

Generic training programs have limited impact. Targeted training addresses the most common defects seen in actual production. Operators learn what goes wrong and why. This approach directly reduces rework and inspection pressure. Fewer defects mean faster flow through the production line.

Training addresses:

- Most common defect types

- Root causes behind mistakes

- Correct techniques for critical operations

Results include:

- Higher first-pass quality

- Less rework

- Shorter inspection cycles

Supervisor Accountability and Feedback Loops

Training must be reinforced by supervision. Supervisors who monitor quality trends and provide immediate feedback prevent errors from repeating. Accountability ensures lessons are applied, not forgotten. Strong feedback loops shorten correction time and stabilize output quality.

Strong systems include:

- Supervisor review of defect trends

- Immediate feedback to operators

- Accountability for repeated issues

Discipline keeps quality stable and predictable.

Timeline Strategies: Plan for Quality Without Slowing Delivery

Delays often occur because quality activities are not built into the schedule. When inspections are treated as add-ons, they collide with shipment deadlines. Proper planning removes this conflict. Realistic schedules acknowledge that quality takes time, but inefficient correction takes much more.

Parallel Processing: Speed With Discipline

Parallel processing allows inspection and production to overlap. While one batch is inspected, the next batch begins production. This maintains momentum and shortens lead time. However, this strategy only works with fast communication and escalation. Without immediate feedback, defects repeat across batches and increase rework risk.

Parallel processing allows:

- One batch under inspection

- Another batch entering production

Benefits include:

- Shorter total lead time

- Continuous workflow

However, this only works if:

- Inspection feedback is immediate

- Escalation is fast

- Production reacts without delay

Without control, parallel processing multiplies mistakes.

Strategic Buffers at Critical Points

Small time buffers placed after major inspection stages absorb unexpected issues. These buffers protect final shipment dates without extending total lead time. Buffers work best when they are planned, not added in panic.

Effective buffer placement:

- After major inspections

- Before final packing

- Before booking deadlines

Planned buffers prevent panic-driven delays.

Technology as an Accelerator, Not a Solution

Digital tools can dramatically reduce inspection and reporting time. Mobile checklists, automated measurement systems, and real-time dashboards improve speed and accuracy. However, technology does not fix weak authority or poor discipline. It accelerates existing systems, good or bad.

Digital Inspection and Reporting Tools

Digital tools reduce manual paperwork and speed up reporting. Inspectors complete checks faster, and data becomes instantly available. This shortens decision cycles and approval times. Automation works best when processes are already clear and standardized.

Digital systems:

- Reduce paperwork time

- Improve data accuracy

- Speed up reporting to buyers

This leads to:

- Faster approvals

- Fewer misunderstandings

- Shorter decision cycles

Automated Measurement and Vision Systems

Automated systems provide fast, consistent measurements. They reduce human error and improve repeatability. For critical dimensions, automation saves time while improving reliability. Technology supports quality when used as a tool, not a substitute for management.

Automation provides:

- Instant measurements

- Consistent results

- Reduced human error

Best used for:

- Critical dimensions

- High-volume styles

- Repeat programs

Communication and Escalation: Stop Small Issues From Becoming Delays

Many quality delays are caused by slow decisions, not technical failures. Unclear communication allows minor issues to grow into major disruptions. Clear escalation rules ensure problems reach decision-makers quickly and actions happen without delay.

Escalation Protocols and Decision Speed

Defined escalation levels clarify who decides what and how fast. This removes uncertainty and prevents issues from stalling on the production floor. Fast decisions protect timelines. Without escalation discipline, even small defects can freeze production. Strong escalation systems define:

- Who decides

- How fast decisions must be made

- What happens if no response is given

Speed protects timelines more than perfection.

Buyer Communication and Approval Timing

Factories can move quickly, but buyer approvals matter. Delays often occur when feedback or approvals arrive late. Proactive communication keeps buyers informed and engaged. Quality speed depends on both factory execution and buyer responsiveness.

Best practices include:

- Real-time quality updates

- Early warning on risks

- Clear approval deadlines

Quality speed depends on both sides acting quickly.

Conclusion: Quality Control Protects Shipments When Done Correctly

Quality control does not delay shipments by default. Delays come from late detection, weak authority, slow decisions, and reactive systems. When quality is integrated into every production phase, it becomes a stabilizing force. Factories that succeed build discipline, plan intelligently, empower inspectors, and communicate clearly. Quality stops being a risk to timelines and becomes their strongest protection.

Factories that succeed:

- Detect problems early

- Empower inspectors

- Plan realistic timelines

- Communicate clearly

When quality is built into production, shipment dates stop being fragile and start being reliable.

Our Contact Information – MEKONG GARMENT FACTORY

- Vietnam Phone: +84 947 729 829

- WeChat: +84 947 729 829

- WhatsApp: +84 947 729 829

- Email: hanh@kimmy.vn