threads are the backbone of every garment, and when you understand the twelve common industrial sewing threads used in the industry, your choices will ensure stronger seams, better aesthetics, and appropriate performance across fabrics from voile to denim; this guide explains composition, advantages, and selection tips so you can match cotton, polyester, nylon, silk, rayon, Kevlar and blended options to the right product and production setting.

About Industrial Sewing Threads

Every garment starts with fabric and thread. In industrial sewing, thread serves as the essential connector that joins materials together, enduring the strain of sewing machines and daily wear. Depending on the fabric type and purpose, different threads are chosen to balance durability, flexibility, and aesthetics. Industrial sewing threads are typically made from:

- Natural fibers: such as cotton and silk, offering softness and breathability.

- Synthetic fibers: like polyester and nylon, known for their strength and resistance.

- Blended fibers: combining both types for improved performance.

Natural Fiber Threads

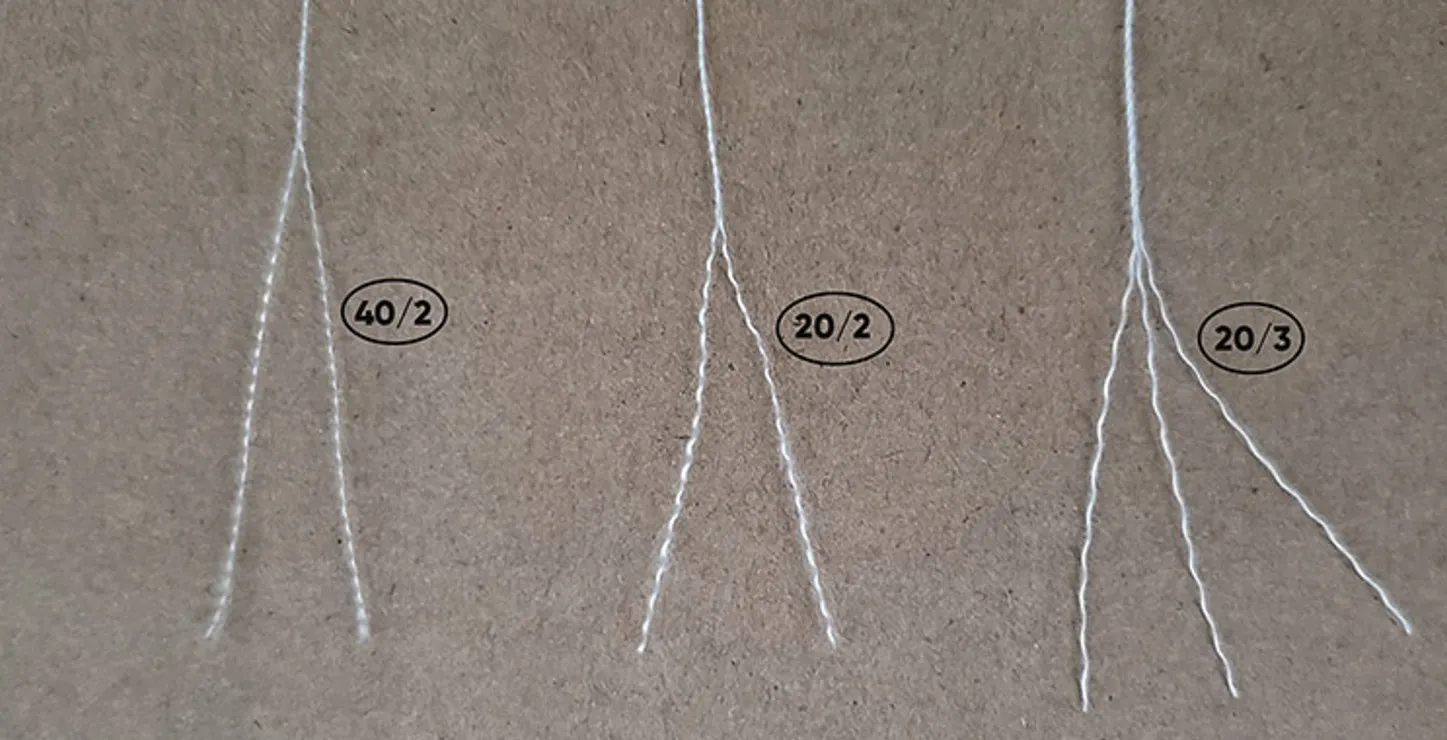

You’ll find cotton and silk dominate natural-thread options: cotton gives a soft hand, good dye uptake and tolerates high-heat pressing, making it ideal for poplin, shirts and quilting; silk delivers a smooth, low-bulk finish suited to luxury garments and fine hems. In practice, you’ll typically select 40–60 wt cotton for general seams and finer silk weights for couture details to preserve the garment’s drape and appearance.

Synthetic Fiber Threads

You should use polyester or nylon when strength, abrasion resistance and consistent dye performance matter: polyester is the go-to for general-purpose and high-speed production; nylon is chosen where stretch recovery is required, such as swimwear and technical apparel. For heavy-duty seams you’ll commonly specify 30–40 wt high-tenacity polyester to avoid seam failure under repeated stress.

In production you’ll consider finishes and filament construction: bonded polyester reduces fluff and breaks on high-speed machines, while textured nylon provides better stretch. For topstitching or outdoor gear you might select UV- and chemical-resistant polyester; for seams that must flex, choose nylon or polyester with a textured/elastic finish. Practical examples: use bonded 40 wt polyester for jeans topstitching and textured nylon for activewear panel joins to maintain recovery and abrasion resistance.

Blended Fiber Threads

You’ll often select blends to combine appearance and performance: cotton-wrapped polyester gives a natural cotton hand with polyester strength, making it common in shirting and visible seams; polyester-rayon blends are standard for embroidery to add sheen and color vibrancy while retaining durability. Blends let you match the look of the garment fiber while improving seam longevity.

Operationally, blends reduce differential shrinkage and improve dyeing compatibility versus pure synthetics; they also let you fine-tune needle selection and machine tension cotton-wrapped cores require slightly different settings than filament polyester. For example, use cotton-wrapped polyester in dress shirts to maintain a natural finish during pressing while preventing seam breaks in high-wear areas.

12 Types of Industrial Sewing Threads

Each type of sewing thread serves a specific purpose. Understanding their composition, advantages, and limitations helps manufacturers choose the most suitable one for every product line from lightweight shirts to heavy-duty workwear.

| Thread Type | Key Features | Advantages | Limitations | Common Uses |

|---|---|---|---|---|

| Cotton Thread | Natural fiber, soft, heat-resistant | Easy to dye, smooth finish, good for high-temp pressing | Low strength, weak when wet, can shrink | Shirts, light garments, cotton fabrics |

| Polyester Thread | Synthetic, strong, colorfast | High tensile strength, resists shrinking and mildew, stable | Slight stretch under heat, not as soft as cotton | General garments, denim, uniforms |

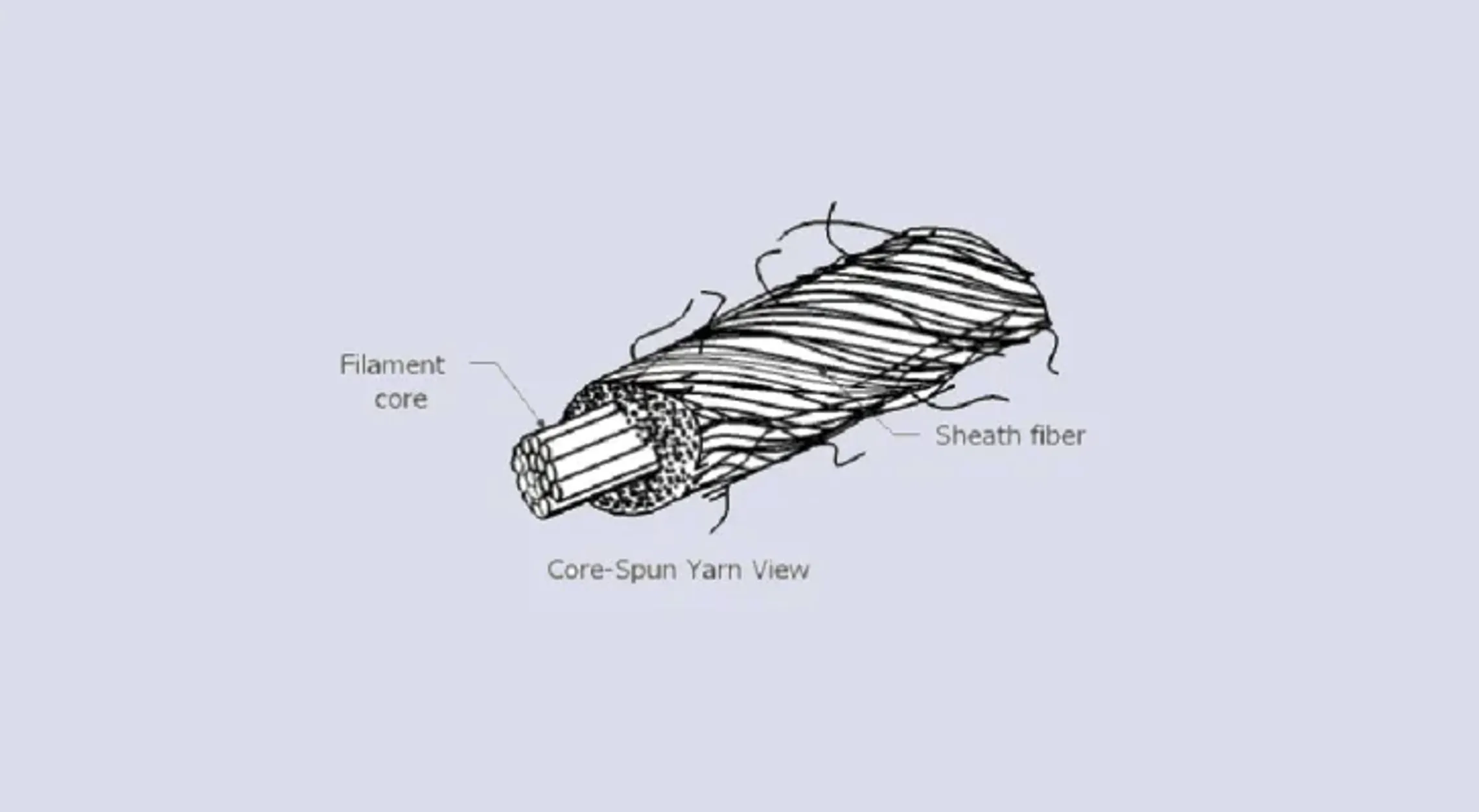

| Core-Spun (Poly-Cotton) | Polyester core wrapped in cotton | High strength + natural look, smooth stitching | Can fuzz or break with poor tension | Jeans, uniforms, heavy-duty sewing |

| Nylon Thread | Elastic, tough, smooth | Excellent stretch, abrasion-resistant, flexible | Weak under sunlight (UV sensitive) | Swimwear, lingerie, leather goods |

| Rayon Thread | Lustrous, soft, smooth | Brilliant sheen, ideal for embroidery | Low tensile strength, poor moisture resistance | Embroidery, decorative stitching |

| Aramid (Kevlar/Nomex) | Flame- and heat-resistant | High temperature tolerance, non-melting | Expensive, stiff, color options limited | Safety gear, gloves, fire-resistant suits |

| Metallic Thread | Metal-coated or laminated | Shiny appearance, adds luxury | Frays easily, hard to sew, needs low tension | Embroidery, fashion details, logos |

| Woolly Nylon | Textured and stretchy | Excellent elasticity, covers seams neatly | Weak at high temperature, frays easily | Overlock seams, lingerie, knitwear |

| Silk Thread | Natural protein fiber, smooth | High strength-to-size ratio, fine and elegant | Expensive, affected by moisture and sunlight | Luxury garments, silk fabrics, tailoring |

| Bonded Nylon | Coated synthetic fiber | Strong, reduced friction, smooth feeding | Loses strength under sunlight | Leather goods, upholstery, footwear |

| Bonded Polyester | UV-resistant coating | Excellent outdoor durability, maintains strength when wet | Slightly less flexible than nylon | Outdoor gear, car seats, bags |

| Textured Polyester (Texturised) | Soft, bulky, stretchy | Provides good seam coverage, comfortable feel | Lower tensile strength | Knitwear, underwear, coverstitch seams |

Threads for Common Fabrics

For cotton shirts use 40-weight polyester or cotton-wrapped polyester; for denim and workwear select high-tenacity polyester or bonded nylon (Tex 50–80) and a topstitch 30-weight cotton-wrapped polyester; for knits use polyester core-spun (30–40wt) to retain stretch; for silk or luxury pieces choose silk or rayon-luster threads; for upholstery choose bonded nylon/polyester Tex 70+. Match needle type (ballpoint for knits, sharp for woven) to the fabric.

Core-spun threads combine a strong polyester sheath with a softer core, giving you needle tolerance, elastic recovery, and abrasion resistance ideal for knits and high-speed lines. Bonded threads have a resin coating that reduces fraying and breakage in heavy sewing or bar-tacking; choose bonded polyester for jeans crotch seams and bonded nylon for marine or outdoor gear. In practice, run a 100 – 200 m production-speed sample with your selected thread, needle, and tension settings to confirm seam appearance and perform a seam-strength pull test before bulk runs.

Kevlar Threads

You’ll choose Kevlar (aramid) thread when heat and cut resistance matter: it retains strength under high temperatures (decomposes above ~400–450°C) and offers exceptional tensile and abrasion resistance compared with polyester. Commonly used in firefighter gear, welding aprons, racing suits, and industrial gloves, Kevlar thread is often spun or bonded and paired with heavy needles (e.g., 90/14–150/22) and slower machine speeds to avoid filament breakage during production.

Thread for Embroidery

You’ll select rayon for maximum sheen or polyester for superior colorfastness and UV/wash resistance; both come in common embroidery weights such as 30–40 wt for decorative satin and fill stitches. Rayon gives brilliant luster for logos and fashion details, while polyester is preferred for sportswear and outdoor items because it resists bleaching, fading, and puckering at high stitch densities.

For best results you should match thread type to stabilizer, needle, and machine speed: use sharp or ballpoint needles sized 75/11 – 90/14 depending on fabric, a polyester bobbin thread (60 – 70 wt) for strength without bulk, and medium to low tension for high-density designs. In production runs, run colorfastness and wash tests (AATCC standards) on sample garments many factories keep 200 – 500 embroidered items as process controls to monitor puckering, thread breakage rates, and color performance across wash cycles.

Threads for Heavy-Duty Applications

You’ll rely on bonded nylon or high-tenacity polyester for heavy-duty seams in upholstery, denim, canvas goods, tents, and automotive interiors; these threads are treated (bonded or waxed) to improve abrasion resistance and reduce fraying. Typical uses include topstitching, bartacks, and seat seams where you need long-lasting, visible stitches that withstand repeated mechanical stress.

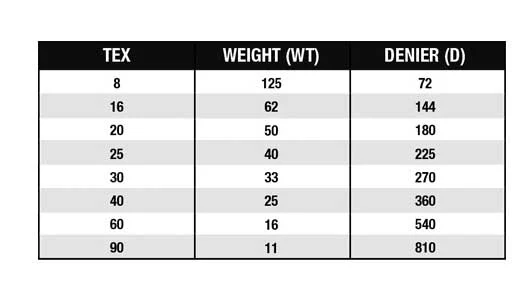

When specifying heavy-duty thread, select filament construction and higher denier/tex counts and pair with oversized needles (110/18–200/23) and slow, high-torque machines. Techniques like bonded thread, triple-stitch seams, bar tacking, and seam sealing increase seam load capacity; for example, military and outdoor gear manufacturers often require bonded polyester threads plus seam reinforcement to meet ISO and MIL-SPEC durability targets during pull and abrasion testing.

How to Choose the Right Thread for Each Product

Selecting the correct sewing thread depends on the fabric, product function, and expected stress level of each seam. Here’s a quick guide:

- For light fabrics (voile, poplin, cambric): choose cotton or fine polyester thread for smooth, flexible seams.

- For denim, canvas, or thick materials: use high-tenacity polyester or nylon thread for maximum durability.

- For luxury garments: select silk or rayon to enhance shine and softness.

- For protective or fire-resistant clothing: Kevlar thread is the top choice due to its exceptional strength and heat resistance.

Always test the thread with the intended fabric before mass production tension, needle type, and machine setting can affect performance.

Summing up / Final Word

On the whole, you should base thread choice on fabric, function and stress: cotton or fine polyester for light fabrics, high-tenacity polyester or nylon for heavy-duty items, silk or rayon for luxury, and Kevlar for protective wear; proper testing of tension, needle and machine settings ensures seam strength, appearance and longevity, helping you deliver high-quality garments that meet your customers’ expectations.

FAQs About Common Types of Industrial Sewing Threads

What are the 12 common types of industrial sewing threads used by garment manufacturers like Mekong Garment Vietnam?

The 12 common types are: 1) Cotton thread: natural, soft, breathable for light fabrics; 2) Mercerized cotton: smoother, stronger and more lustrous than raw cotton; 3) Polyester thread: versatile, strong, colorfast for general use; 4) High-tenacity polyester: extra-strong for heavy-duty seams; 5) Nylon (polyamide): high elasticity and abrasion resistance; 6) Bonded nylon: coated for extra strength and reduced fuzz; 7) Rayon thread: high sheen for decorative and luxury garments; 8) Silk thread: smooth, fine and strong for couture finishes; 9) Polyester-cotton (core-spun/blended): balances strength and hand; 10) Kevlar/aramid: heat- and cut-resistant for protective wear; 11) Elastic/covered elastic thread: for stretch or stretch seams; 12) Monofilament (nylon or polyester): translucent, used for invisible seams and specialized applications.

How do polyester and nylon threads differ, and when should each be used?

Polyester offers excellent UV and chemical resistance, low shrinkage, good dimensional stability and broad compatibility with fabrics use it for shirts, outerwear, and general production. Nylon is stronger and more elastic with superior abrasion resistance, making it better for heavy-duty items Iand where stretch recovery is needed. Polyester tolerates higher temperatures in finishing better than nylon; choose based on fabric type, expected stress and finishing processes.

When are natural threads like cotton, rayon, or silk preferable?

Use cotton for lightweight, breathable garments (shirts, blouses) and when a soft hand and matte finish are desired. Rayon provides a high sheen and is chosen for decorative stitching and luxury-looking seams on dress fabrics where appearance matters more than extreme strength. Silk is selected for high-end tailoring and couture where strength, smooth feed and a premium finish are required. For each, test seam performance, shrinkage and colorfastness with the target fabric.

What is bonded thread and what production uses benefit most from it?

Bonded thread has a surface coating Iapplied to filaments or plied yarn to increase tensile strength, reduce lint and improve abrasion resistance. It is ideal for heavy seams, topstitching, high-speed sewing, outdoor garments, leather goods and upholstery where seam durability and reduced machine lint are priorities. Bonded threads also improve stitch appearance and reduce breakage on industrial machines.

Which threads are best for denim, canvas and other heavy fabrics?

For denim and canvas, choose high-tenacity polyester, bonded nylon or heavy-weight corespun/polyester-cotton topstitching threads. Use thicker thread counts for visible topstitching and reinforced seams, matched with heavy-duty needles and adjusted machine tension. Pre-test stitch density, seam allowance and wash cycles to ensure seam durability and appearance under heavy wear.

What thread types are recommended for protective, flame-resistant or stretch garments?

Protective and flame-resistant garments typically use aramid fibers such as Kevlar for exceptional heat, cut and flame resistance. For stretch garments, use elastic-covered threads, polyester-wrapped spandex or stretch-specific core-spun threads to preserve elasticity and seam recovery. Match the thread’s mechanical properties to the garment’s protective or stretch requirements and validate with performance testing.

What are best practices for matching thread to fabric, machine and production processes?

Produce sample seams using the intended fabric, thread, needle type and stitch settings; then test wash, wear and finishing processes. Match thread size and strength to fabric weight and seam load; choose bonded or glazed finishes for high-speed sewing; select the correct needle point and size to minimize skipped stitches and fabric damage; adjust tension and stitch length for seam appearance and durability; verify colorfastness and chemical compatibility with finishes and detergents before mass production.