Over a wide range of applications, you’ll find polyethylene (PE) fabric delivers high strength-to-weight, reliable water resistance, chemical and UV resilience, and economical production, so you can specify it for outdoor gear, covers, tarps, and industrial uses where durability and cost matter more than softness or breathability; however, you should be aware of its limited heat resistance, low elasticity, non-breathability for clothing, and environmental persistence when evaluating suitability for your projects.

Overview of Polyethylene Fabric

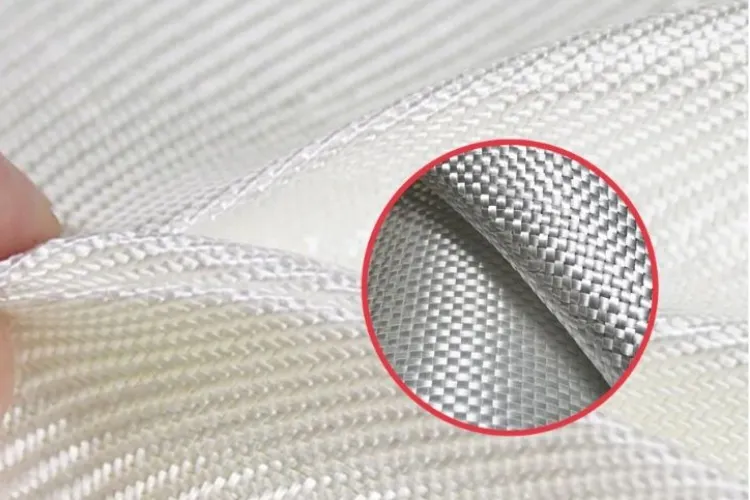

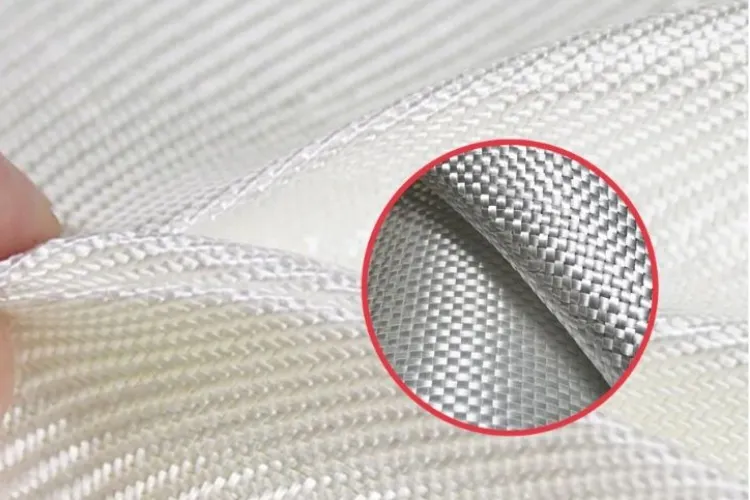

You work with a synthetic thermoplastic made from polymerized ethylene; polyethylene (PE) fabric appears as woven, nonwoven, coated, or laminated sheets and fibers. Densities range roughly 0.91-0.96 g/cm³, with melting points commonly between 105-135°C depending on grade (LDPE, HDPE, LLDPE). You’ll find PE used where waterproofing, chemical resistance, and low cost matter more than softness-think tarps, geotextiles, packaging films, and industrial liners.

You’ll encounter several distinct PE categories: LDPE (flexible film and coatings), HDPE (stiffer woven fabric and geotextiles), LLDPE (higher tear resistance for films), UHMWPE fibers (high-strength ballistic and rope applications), and coated/laminated variants (PVC or PE films laminated to woven substrates). Applications span agriculture, construction, packaging, and personal protective gear; UHMWPE fibers deliver exceptional strength-to-weight for cut- and impact-resistance.

Common Types and Categories:

- LDPE film and coated fabrics – flexible, good for low-temperature sealing

- HDPE woven fabric – used in sacks, tarps, geotextiles

- LLDPE films – improved puncture and tear resistance for stretch films

- UHMWPE fiber fabrics – Dyneema/Spectra-class use in ballistic, marine ropes

- Knowing you should match grade to load, temp, and UV exposure for best results.

| LDPE | Flexible film/coatings; film thickness 20-200 µm; good cold flexibility |

| HDPE | Stiff woven fabric; common GSM 100-600 g/m²; used in geotextiles and sacks |

| LLDPE | Higher tear resistance; used in stretch/packaging films and heavy-duty sheeting |

| UHMWPE | High-tenacity fiber fabrics; tensile strength per weight exceeds many steels |

| Coated/Laminated PE | PE film laminated to woven or nonwoven base; film thickness 50-500 µm for waterproofing |

Pros and Cons of PE Fabric

Advantages What PE Fabric Excels At

Because of its nature and manufacturing flexibility, PE fabric delivers a compelling package of advantages:

- Strong strength-to-weight ratio — gives durability without bulk, easy to handle and transport.

- Consistent waterproof / water-resistant behavior — ideal for outdoor, wet, humid, or moisture-exposed environments.

- Chemical and weather resistance — withstands exposure to many chemicals, solvents, acids/bases; resists UV, mildew, and environmental degradation (especially with proper coatings).

- Tear/Puncture/Abrasion resistance — good for rough handling, heavy loads, repeated use.

- Flexibility & processability — can be woven, coated, laminated; sized and finished to suit many different needs.

- Cost-efficiency — PE resin is relatively inexpensive; production is efficient; final products are affordable.

- Versatility — works across a broad spectrum of industries and uses — from agriculture to shipping to construction to outdoor gear.

These traits make PE fabric a go-to material when performance, durability, and cost matter more than “luxurious feel” or “fashion fabric” sensibilities.

Strength-to-Weight Ratio

You benefit from PE’s low density (about 0.91-0.96 g/cm³) which, combined with high tensile strength in engineered grades, delivers impressive strength-to-weight performance; that’s why you see PE used in lifting slings, ropes and UHMWPE-based ballistic fabrics where durability without bulk matters.

Waterproof and Water-Resistant Properties

You get reliable water protection: uncoated PE film is imperatively impermeable, and woven PE with coatings forms tarps, pond liners and truck covers that keep moisture out in wet, humid, or rainy environments. In practice, waterproof performance depends on construction and seam technique: laminated or coated PE fabrics achieve true waterproofing, while welded seams (hot-air or heat welding) prevent leakage better than stitched seams. Typical uses-pond liners, greenhouse covers and cargo tarps-rely on PE’s low water absorption and ability to withstand repeated wet/dry cycles without dimensional change.

Chemical and Weather Resistance

You can use PE where exposure to many common chemicals, dilute acids, alkalis and hydrocarbons is expected; its inherent resistance makes it suitable for chemical covers, containment liners and outdoor installations exposed to the elements.

That said, PE is vulnerable to strong oxidizers and certain aromatic solvents, so selection matters: carbon-black loaded or UV-stabilized PE extends outdoor life, and adding stabilizers can move expected field life from months to several years depending on UV exposure. For chemical containment, you should match grade (LDPE vs. HDPE vs. UHMWPE) to the specific aggressors and temperatures involved.

Tear, Puncture, and Abrasion Resistance

You’ll find PE performs well under rough handling: woven scrims and coated constructions resist tearing and puncture, which is why industry uses include construction sheeting, heavy-duty tarpaulins and erosion control blankets.

Performance scales with yarn denier, weave density and coating type: a 10×10 oz/yd² woven PE with PVC or PE coating will show far greater puncture resistance than a thin film. Manufacturers validate performance using standard tear/puncture tests (ASTM/ISO methods), and reinforcement options like scrim or laminated layers let you tailor resistance to application loads and abrasive contact conditions.

Flexibility and Processability

You can choose from films, woven fabrics, laminates and coated systems; PE accepts heat welding, extrusion coating and lamination, making it easy to fabricate large sheets, custom covers, and complex assemblies.

In manufacturing, PE is forgiving: it can be extruded into films, calendered, or laminated to woven scrims, and joins are typically made by hot-air or wedge welding rather than adhesives. That lets you produce leak-tight geomembranes, sewn-and-welded tarps, or multi-layer barrier films with predictable cycle times and high throughput on standard equipment.

Cost-Efficiency

You pay less for PE resin than many specialty polymers, and low density reduces raw-material mass and shipping costs, so final products like tarps, liners and packaging remain affordable while still meeting performance needs.

From a lifecycle perspective, lower upfront cost and simple manufacturing lower your unit costs; economies of scale in film extrusion and woven production drive prices down further. For many applications the combination of acceptable performance and low cost makes PE the practical choice over more expensive coated nylons or engineered synthetics.

Versatile Applications Across Industries

You’ll find PE across agriculture, construction, shipping, outdoor gear and containment: examples include mulch film, greenhouse covers, temporary shelters, pond liners, and cargo protection.

Concrete case points: in agriculture, LDPE films are common for silage wraps and greenhouse covers; in construction, HDPE vapor barriers and temporary enclosures are standard; and in packaging, PE films meet many food-contact regulations (FDA permits certain LDPE/HDPE uses). This breadth means you can often select PE grades and constructions tailored to cost, durability and regulatory needs.

Limitations & Challenges: What PE Fabric Can’t Do So Well

As useful as PE fabric is, it does have limitations users should know:

- Poor heat resistance — compared to some synthetic or specialized fibers, PE softens or deforms at moderate to high temperatures, limiting its use in high-temperature or flammable environments.

- Low elasticity & stretch recovery — fabrics made from PE tend to be less elastic; under sudden loads or impacts (e.g. shock loads in mooring, heavy lifting) they may not perform as well as more elastic fibers.

- Non-breathable / Low Comfort for Clothing — PE fabric tends to be non-porous and poorly breathable, making it ill-suited for everyday clothing (uncomfortable, poor ventilation). — Because the core value is functional, not comfort or softness.

- Environmental Issues: Non-biodegradable — like most plastics, PE doesn’t biodegrade easily. If disposed improperly, can contribute to long-term plastic waste.

- Limited “High-end textile” Appeal — PE fabric lacks the soft hand-feel, drape, breathability of natural fibers (cotton, wool) or high-performance synthetic textiles. It’s mainly suited for functional, utilitarian uses, not fashion or comfort-focused garments.

Thus, while PE fabric is powerful for practicality, it’s seldom chosen for apparel when comfort or breathability matters.

Poor Heat Resistance

At elevated temperatures PE softens and deforms: LDPE typically melts around 105-115°C and HDPE around 120-135°C, so you cannot rely on standard PE fabric in applications that see sustained heat or open flames. In practice that limits use near ovens, hot industrial surfaces, or where sterilization requires high temperatures; coatings can help marginally, but they don’t convert PE into a high-temperature material.

Low Elasticity and Stretch Recovery

You’ll notice PE fabrics have limited stretch and poor elastic recovery compared with nylons or elastane blends, so they deform under shock loads and can show permanent elongation after heavy use. That makes them less suitable where energy absorption or repeated stretch is required, such as mooring lines or elasticated garments.

For example, nylon webbing commonly stretches 15-30% under load and returns close to its original length, providing shock absorption for lifting or towing; by contrast woven PE tarpaulins and coated sheets stretch far less and often retain some set. When you design gear that must absorb impact or maintain dimensional stability under cyclical loads, you should consider alternatives (nylon, polyester, or hybrid constructions) or reinforce PE with additional layers, webbing, or elastic components to avoid premature deformation or failure.

Non-Breathable Characteristics

Because PE coatings and films are importantly impermeable, you’ll find very low moisture vapor transmission-near zero compared with breathable membranes-so clothing or gear made from PE traps heat and sweat. That limits PE’s comfort use in everyday apparel and in activewear where ventilation matters.

In practical terms, breathable laminates like PTFE-based membranes can show MVTRs in the thousands of g/m²/24h, whereas PE laminates register negligible values; when you need moisture management (workwear, tents for intensive activity), you’ll either add vents, mesh panels, or choose a different fabric system to avoid condensation, clamminess, and reduced wearer performance.

Environmental Concerns Regarding Biodegradability

PE is highly resistant to biological degradation, so if you discard PE products improperly they can persist in the environment for decades and contribute to plastic pollution; while HDPE and LDPE are technically recyclable (resin codes 2 and 4), recycling rates vary and contamination often keeps them out of streams. You should plan end-of-life handling when specifying PE.

Operationally, that means you should design for recyclability-use single-polymer constructions, avoid mixed-material lamination, and label materials clearly-because additives, dirt, and adhesives often render PE fabrics hard to recycle. You can also evaluate take-back programs, mechanically recycled PE content, or look for certified recycled resins to reduce lifecycle impact when you must use PE for functional reasons.

Limited Appeal for High-End Textiles

PE lacks the soft hand, drape, and breathability consumers expect from luxury or fashion textiles, so you’ll rarely see it in high-end garments beyond technical components; its visual and tactile properties are utilitarian rather than premium. That confines PE to functional markets unless blended or finished extensively.

That said, there are niche exceptions: high-modulus polyethylene fibers (UHMWPE) appear in performance products like cut-resistant gloves, ballistic panels, and ultra-light ropes, but these address strength rather than comfort. When you aim for elegance, drape, or next-to-skin wearability, choosing cotton, silk, wool, or engineered performance synthetics will more reliably meet consumer expectations than plain PE fabric.

Conclusion / Final Words

Now you can see that polyethylene (PE) fabric offers durable, waterproof, and cost-effective solutions ideal for industrial, agricultural, and outdoor applications; you should weigh its poor heat resistance, low breathability, limited elasticity, and environmental persistence when selecting materials-Mekong Garment Vietnam provides practical PE options where performance and value trump comfort or high-end textile appeal, so base your choice on intended use, lifecycle, and disposal practices.

FAQS About Pros & Cons of Polyethylene Fabric ( PE Fabric )

In Short, What are the primary advantages of Polyethylene (PE) fabric

PE fabric combines a high strength-to-weight ratio with reliable water resistance, chemical and weather stability, and good tear/abrasion resistance. It is flexible in processing (woven, coated, laminated), cost-effective to produce, and adaptable across industries such as agriculture, packaging, construction, and outdoor equipment.

In Short, What common limitations should buyers consider when selecting PE fabric?

PE fabric has poor heat resistance and can soften under moderate to high temperatures, limited elasticity and stretch recovery under shock loads, and low breathability which makes it unsuitable for everyday apparel. It also lacks the hand-feel and drape of higher-end textiles and contributes to long-term plastic waste if not properly managed.

How durable and weather-resistant is PE fabric for outdoor use?

With proper coatings and UV stabilizers, PE fabric offers excellent resistance to water, mildew, chemicals, and many environmental factors, making it well suited for tarpaulins, covers, and outdoor gear. Durability against abrasion and puncture is strong but depends on weave, weight (gsm), and finishing.

What care and maintenance practices extend the life of PE fabric products?

Clean with mild soap and water; avoid harsh solvents that can damage coatings. Store items dry and out of prolonged direct sunlight when not in use. Repair small tears promptly with suitable patches or adhesives. Avoid prolonged heat exposure and sharp, concentrated impacts that can deform or puncture the material.

How environmentally friendly is PE fabric and what recycling options exist?

PE is a non-biodegradable thermoplastic; improper disposal contributes to plastic pollution. Many PE products can be mechanically recycled where collection and facilities exist. Choosing recycled-content PE, reducing single-use applications, and working with suppliers that offer take-back or recycling programs improves environmental outcomes.