Labelling may seem like a small detail in apparel production, but it’s one of the most important compliance, quality-and-branding elements you’ll face. Proper labels help consumers understand what they’re buying, how to care for it, where it comes from and they protect you from legal risk. The rules vary by country and region, so if you intend to sell internationally you’ll need to know the major requirements in key markets. Below we’ll walk through the what, why, and how of garment labelling, with practical guidance for clothing brands and manufacturers.

Why Labelling Matters

Labels are more than decorative tags they carry legally required information, brand identity, care instructions, and fibre content. They build trust: your customer sees what the item contains, where it’s made, and how to maintain it. From a legal viewpoint, many jurisdictions hold brands and importers responsible if labels are missing or misleading. On the manufacturing side, labelling is also part of traceability, quality assurance, and after-sales service (returns, care). Knowing labelling standards early helps you set up accurate tech-packs and factory instructions.

Key Label Elements Across Major Markets

While the specifics differ from region to region, certain core elements appear repeatedly in labelling regulations. Here are the main ones to focus on:

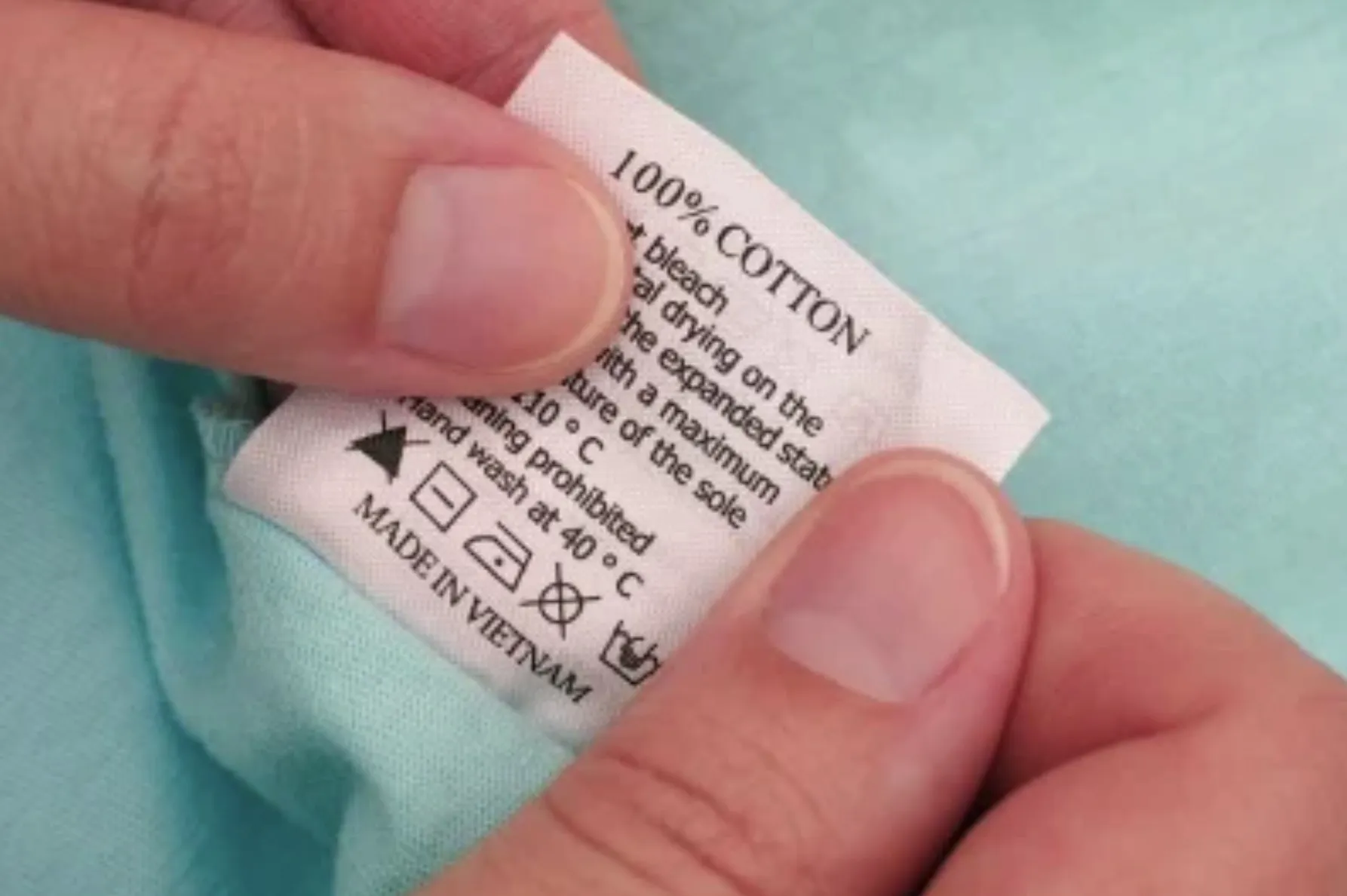

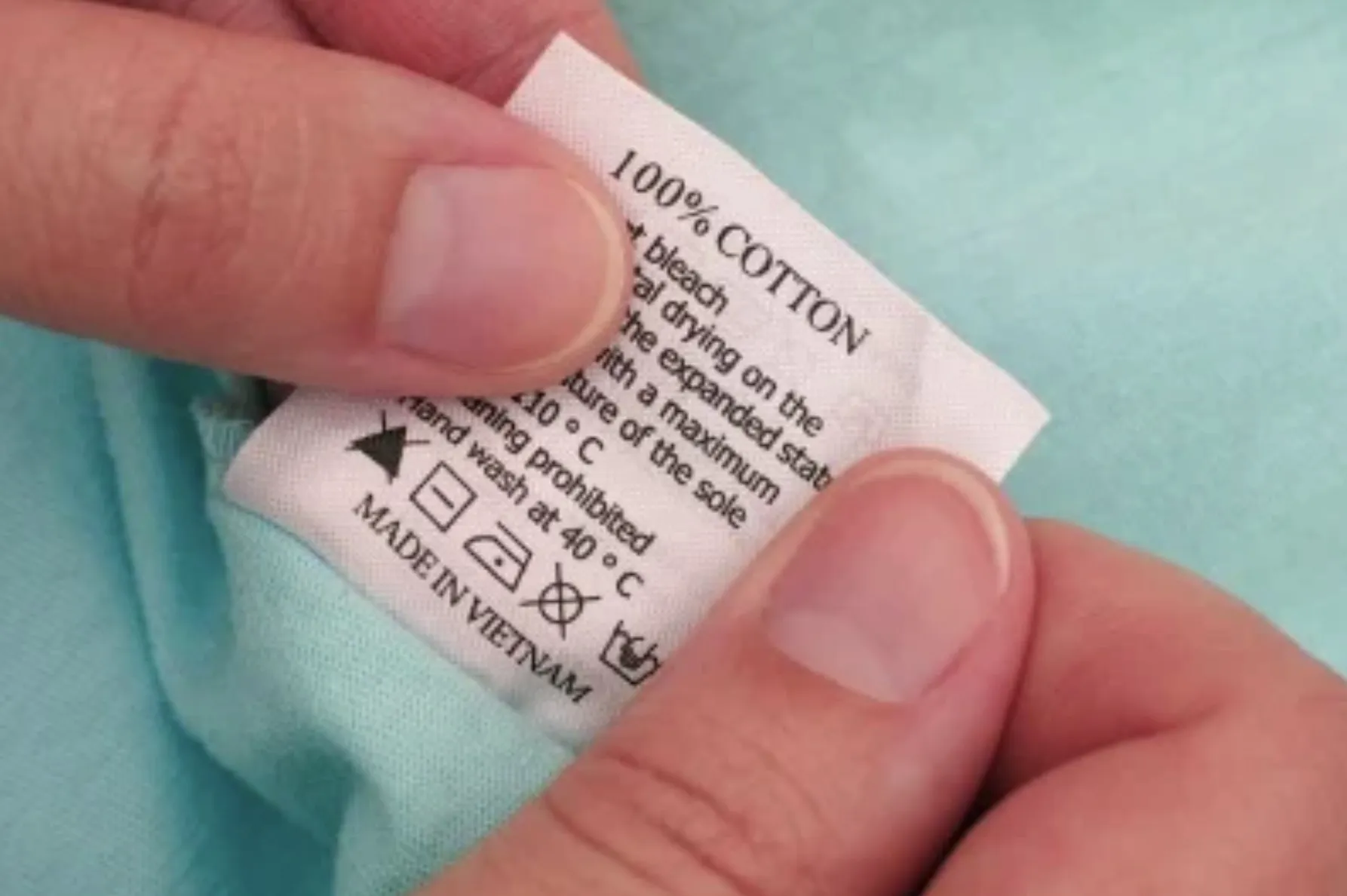

Fibre Composition

Every garment label starts with one crucial detail what the clothing is made from. Fibre composition isn’t just a technical note; it tells buyers the quality, comfort, and care expectations of the item. Governments require this information to ensure product transparency and prevent misleading marketing. Whether you’re using 100% cotton or a blend of polyester and spandex, each fibre must be listed accurately, in descending order by percentage, and using standard fibre names rather than brand terms. This helps consumers make informed choices and ensures fairness across the textile industry. You’ll almost always need to declare what fibres (textile materials) make up the garment. For example: cotton, polyester, wool, etc.

- In the U.S., the Textile Fiber Products Identification Act and the Federal Trade Commission (FTC) require clear labelling of fibre content.

- In the EU, every textile product must be labelled or marked to show its fibre composition whenever it’s placed on the market.

- The rule typically states: list each fibre in descending order by percentage, use generic fibre names (not trade names), include linings/trims if relevant, and exclude very small components (depending on jurisdiction).

Country of Origin

Where a garment is made affects everything from customs classification to consumer perception. The country-of-origin label is legally required in many markets to prevent false claims and promote supply-chain transparency. For example, “Made in Vietnam” or “Made in USA” must only be used if the majority of production actually happens in that country. Brands often overlook this detail, but mislabelling can lead to fines, shipment delays, or loss of trust. Always confirm origin documentation from your factory to ensure full compliance. Consumers and regulators want to know where a garment was made (or assembled).

- In the U.S., the “Made in …” label must be accurate: e.g., “Made in USA” only if virtually all manufacturing and materials are U.S.-origin. Otherwise you might say “Made in USA of Imported Materials”.

- In the EU, labelling the country of origin is not harmonised for all textiles, but fibre content is mandatory and authorities may check origin as part of conformity assessments.

Care Instructions

Care instructions protect both your brand and your customers. They guide users on how to wash, dry, iron, or dry-clean the garment properly to maintain its look and lifespan. Including clear, easy-to-understand instructions or internationally recognized care symbols prevents damage complaints and returns. In some countries, like the United States or Australia, care labelling is mandatory and governed by strict rules. The key is clarity use either written text or universal care icons, and make sure they remain readable even after many washes. How the consumer should wash, dry, iron, clean or otherwise maintain the garment is critical both legally (in many jurisdictions) and from a brand/care perspective.

- In the U.S., under the FTC’s Care Labelling Rule, manufacturers and importers must provide instructions for the regular care of textile garments.

- In Australia, for example, the mandatory standard for “Care labelling for clothing and textiles” requires either English written instructions or the 5 internationally recognised care symbols (or both).

- Within the EU, while care instructions might not always be strictly required by law for every product, failing to provide them could expose you under product liability.

Manufacturer/Importer/Brand Identification

Labels should clearly identify who made or imported the garment. This helps regulators trace the source if there’s an issue and allows customers to contact the responsible company. Depending on the country, you may need to include a registered company name, address, or identification number (such as the RN number in the U.S.). This level of transparency not only fulfills legal requirements but also strengthens your brand credibility. It tells the customer that your business stands behind its product quality. Regulators often require you to identify who is responsible for placing the garment on the market (manufacturer, importer or brand).

- In the U.S., textile products must carry the Registered Identification Number (RN) of the manufacturer, importer or marketer, or a combination of that + the name.

- For other regions, while requirements may vary, having clear brand/traceability info is considered good practice and may be mandatory.

Label Placement & Durability

It’s not enough to include the right information it must also be placed and attached correctly. Label placement affects both visibility and comfort, while durability ensures the text remains readable for the garment’s lifetime. Regulations in major markets require labels to be securely sewn or printed on, using materials that withstand washing and wear. Always check placement standards (like inside the neck or waistband) and test sample labels under real washing conditions. A faded or detached label can lead to compliance problems and poor customer experience. It’s not enough to include the right data you must attach it properly and ensure it remains legible for the life of the garment.

- In the U.S., the FTC states that required info must be “attached to the article at the time of importation” and remain until the garment reaches the consumer.

- In the EU, labels must be “firmly attached” and legible, and the text must be clearly separated (in layout) from other info.

Special Considerations for Specific Regions

If you’re exporting, remember that each region has its own labelling laws. The United States, European Union, Australia, and Canada all enforce different standards for fibre disclosure, care instructions, and language use. For example, EU labels must list fibre composition in all official languages of the destination country, while Australia requires English care instructions. Before production, confirm each target market’s specific regulations to avoid re-labelling costs or border rejections. Staying proactive saves both money and reputation.. When you’re selling internationally (or sourcing globally), you’ll want to tailor labels to comply with each market.

- United States: The FTC oversees textile labelling; fibre content, country of origin and manufacturer/marketing identity are core.

- European Union: Fibre composition labeling is mandatory; care instructions may be voluntary but advisable; language and durability matters.

- Australia / New Zealand: There are care-labelling specific mandatory standards (e.g., AS/NZS 1957:1998) that require English instructions and/or symbols.

- Canada: Under the Textile Labelling and Advertising Regulations managed by the Competition Bureau Canada, textile articles must carry certain fibre-content labeling when sold in Canada.

Practical Steps for Clothing Brands & Manufacturers

Labelling should be planned early not after production begins. Create a dedicated section in your tech pack that specifies every detail: label content, size, material, and placement. Choose durable label fabrics like satin or woven polyester, especially for garments that will endure heavy washing. Always test sample garments for label readability and comfort, then adjust if needed. Keep updated records of your labelling specifications, supplier information, and any certifications; these can be vital during customs inspections or audits. Here are actionable steps to ensure your garments are labelled correctly (and your supply-chain/compliance is set up for it):

- Create a label-spec sheet in your tech-pack: specify fibre breakdown, country of origin, care instructions (text + symbols), brand/manufacturer ID, size info, placement specs (which label piece, where on garment).

- Select durable label materials: labels must survive the life of the garment (wash, wear, abrasion). Poor quality labels = compliance risk + brand disappointment.

- Map regional requirements: For each target market, note any unique or additional requirements (language, symbol set, warning labels for children’s wear, etc.).

- Test sample labels: Stamp one of your garments, wash it, iron it, tumble-dry it (if applicable) to see if the label remains legible and intact.

- Maintain documentation: Keep records of label specs, suppliers, amendments. If regulators ever ask, you’ll want proof you followed the rules.

- Communicate with your manufacturer: Make sure your factory (or CMT partner) understands label placement, materials, required information. Provide them with your label spec sheet and review sample label before full run.

- Update when required: Regulations evolve especially around sustainability, origin-claims, care symbols. Stay current so you don’t ship non-compliant stock.

Common Pitfalls & How to Avoid Them

Even experienced brands sometimes get labelling wrong. Common errors include using trade names instead of generic fibre terms, misprinting the country of origin, or forgetting to list blended materials accurately. Others use low-quality labels that fade after the first wash, leading to customer complaints. Failing to update information when changing factories or materials is another major oversight. Always double-check final proofs before mass production — one small mistake can make an entire shipment non-compliant.

- Using trade names instead of generic fibre names – e.g., “Micro-polyester” vs “polyester” may trigger non-compliance.

- Omitting or misstating fibre percentages or non-textile parts – For example, not marking animal-origin non-textile components when required.

- Label falling off or becoming illegible after first wash – A costly brand mistake and compliance hazard.

- One-size-fits-all label for multiple markets – Sometimes fine, but if you ship to multiple jurisdictions with stricter rules you may need variant labels.

- Ignoring children’s wear specific rules – For example, flame-hazard warnings for nightwear, etc.

- Failure to update when regulations change – Some jurisdictions are tightening origin, sustainability, traceability claims.

Summary / Final Words

In the apparel world, labelling is far more than a hang-tag: it’s a legal obligation, a brand promise and a consumer service. For fibre content, origin, care instructions, and responsible identification, you must align with the applicable regulations of each market. Getting this right builds trust, avoids fines, and keeps your supply-chain smooth. For your next clothing collection, treat the label as part of your tech-pack, not an after-thought. Do it early, clearly, and correctly.