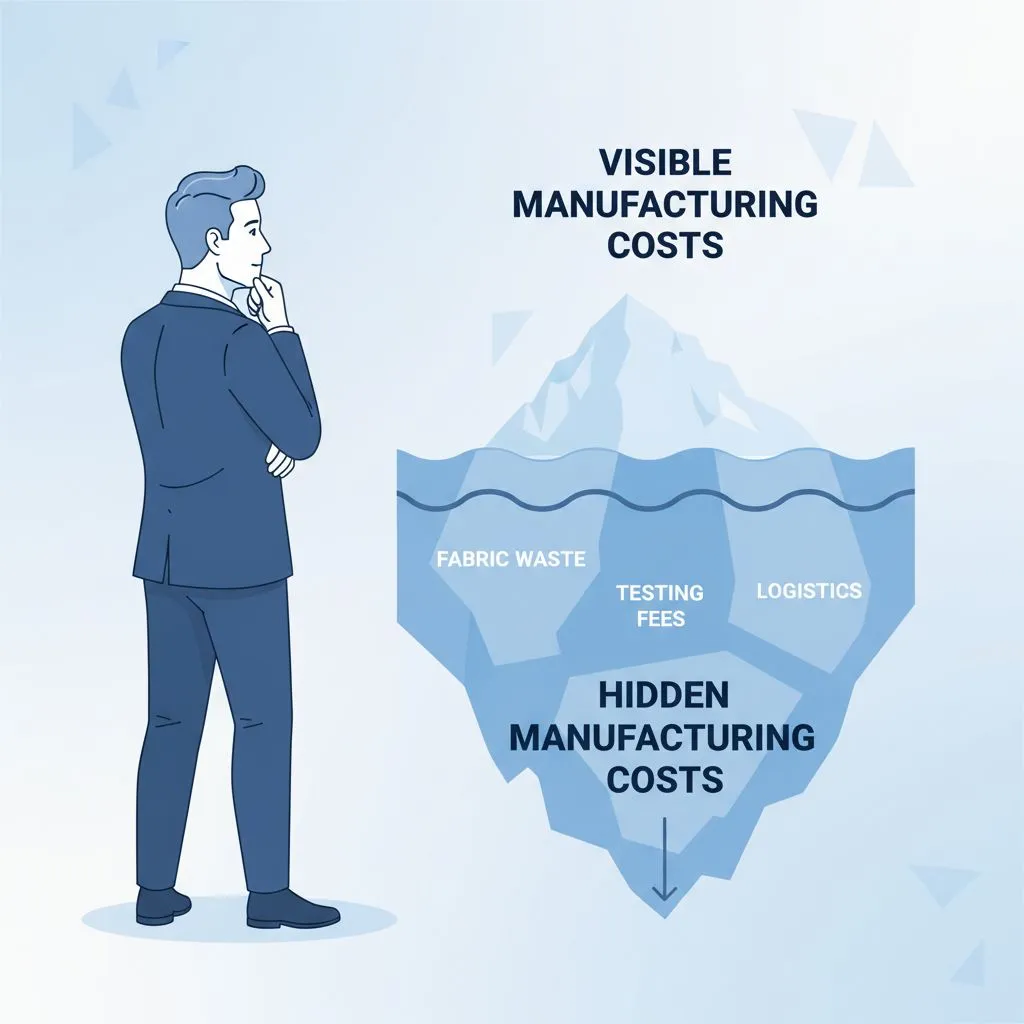

+6 Hidden Costs in Garment Manufacturing in Vietnam?

You get a quote. The unit price looks great. You start to picture profit. Then reality taps the shoulder. The unit price is often only the factory making cost. Your true cost is the total landed cost. That includes development, waste, tests, quality checks, shipping fees, and import charges. These “hidden” costs are not magic. They happen for one simple reason: The quote did not define the full scope. So the factory priced what you asked for, not what you assumed. Let’s make the full cost visible, with real numbers and a checklist you can use today.

Why “Hidden Costs” Happen (and why it’s partly your fault)

Many extra costs are not “hidden.” They are unspecified.

If your quote says only:

- fabric type (maybe),

- unit price,

- MOQ,

- lead time,

…then it is normal for extra charges to appear later. A factory cannot guess:

- how many sample rounds you need,

- what tests your market requires,

- what defect rate you accept,

- who pays for customs,

- what packaging details you want.

So the cure is not “find a cheaper factory.” The cure is: turn the quote into a complete cost map.

The 6 Biggest Hidden Cost Buckets

Pre-production development costs

Before a single piece is cut, you pay for the work that makes production possible. Patterns, grading, and tech pack cleanups often sit outside the factory’s unit price. Sampling also grows fast because most styles need more than one fit revision. If you don’t set a sampling plan upfront, “free sample” can turn into paid rounds. These costs feel small at first, but they quietly stack into a serious starting bill.

Common items:

- Pattern making

- Grading (sizes)

- Tech pack cleanup

- Sample rounds (proto, fit, size set, PP sample)

- Lab dips and strike-offs (prints, embroidery)

Why it surprises brands: Many factories offer a “free first sample,” then charge for revisions. And most styles need revisions. How to control it: Put a sampling schedule in writing.

- How many rounds are included?

- Cost per extra round?

- Cost per size set?

Testing and certification fees

Testing is the price of entering real markets, not an optional extra. Many brands assume the factory will include lab fees, but most quotes only cover manufacturing. Fabric and product tests may be required by your buyer, your product category, or local law. Certifications can also add fees for audits, paperwork, and repeat testing. If you skip this budget line, you risk delays, blocked shipments, or expensive rework later.

Examples:

- Children’s sleepwear in the U.S. must meet flammability rules under 16 CFR 1615/1616, with defined fabric and garment testing steps.

- Certifications like OEKO-TEX STANDARD 100 involve costs tied to the license, audit, and lab/admin testing (exact price depends on product scope).

Why it surprises brands: Factories quote manufacturing. They do not quote your market access work unless you ask.

How to control it? Ask

- What tests are required for my product category in my target country?

- Who pays lab fees?

- What happens if fabric fails?

Fabric waste and marker efficiency

Fabric cost isn’t just “price per meter.” What matters is how much fabric your patterns actually consume in cutting. Complex shapes, many sizes, and poor marker efficiency can raise waste fast. Brands often budget with an optimistic waste rate, then get shocked when actual usage is higher. Even a small jump in waste can add a lot per unit when fabric is your biggest cost. This is why consumption and waste assumptions must be written into your costing sheet.

Key idea: you rarely use 100% of the fabric you buy.

- Marker efficiency depends on pattern shape, sizes, and nesting.

- Complex designs can raise waste a lot.

Why it surprises brands: Many quotes assume a “normal” waste rate. But your style may not be normal.

How to control it: Require two numbers in the costing sheet:

- Fabric consumption per size (meters or yards)

- Assumed waste % (marker loss)

If the factory will not share this, your quote is not transparent.

Trim MOQs and extra inventory

Trims look cheap until you meet supplier minimums. Buttons, zippers, labels, and hangtags often come with MOQs that don’t match your garment order size. You may pay for 10,000 units of a trim to produce only 1,000 garments. That “extra inventory” becomes a hidden cost sitting on your shelf, tying up cash. Smart trim choices and clear MOQ planning prevent this silent budget leak.

Trims include:

- buttons, zippers, snaps

- woven labels

- hangtags, polybags

- thread colors

Trim suppliers often have their own MOQs. That can force you to buy far more than your order needs. Why it surprises brands: Your garment MOQ might be 1,000 pcs, but a custom trim MOQ might be 10,000 pcs.

How to control it: Ask for “MOQ overage cost” up front

- “If trim MOQ is higher than my order, show me the overage cost and what I receive.”

Quality control and inspection costs

Quality is not free. It costs money or it costs pain. Third-party pre-shipment inspections often price by “man-day,” commonly in the hundreds of dollars per day depending on scope and region. Why it surprises brands: Some brands skip inspection to save money. Then defects cost far more than inspection would have.

How to control it: Write down

- Quality standard (AQL level)

- Who pays for rework?

- What happens if the shipment fails inspection?

Logistics, surcharges, and import fees

Shipping is not just “ocean freight.” Shipping is a chain of fees, not one number. Freight is only the headline, while terminal handling, fuel surcharges, documentation, and last-mile delivery hide in the fine print. Importers also face customs bonds, brokerage charges, duties, and port fees depending on the Incoterm. These costs hit at the worst time, right when your goods arrive and cash is already tight. If you don’t model landed cost early, logistics can turn a “profitable” order into a cashflow trap.

You may see:

- terminal handling charges

- peak season fees

- fuel surcharges

Example: Bunker Adjustment Factor (BAF) is a fuel-related surcharge used in ocean shipping.

If you import into the U.S., two common government fees include:

- Merchandise Processing Fee (MPF): the ad valorem rate is 0.3464%, and CBP sets a minimum and maximum that can change with inflation.

- Harbor Maintenance Fee (HMF): often described as 0.125% of the cargo value for ocean imports.

Why it surprises brands: The factory quote usually ends at the factory gate (or at best FOB). Many import fees are on you, not them.

How to control it: First, lock the Incoterm:

- EXW, FOB, CIF, DDP, etc.

Second, ask your forwarder for an “all-in estimate” with a list of typical add-on charges.

A Simple “True Cost” Formula (use this, not unit price)

True landed cost per unit = (Manufacturing + Development + Testing + QC + Freight + Duties/fees + Packaging + Finance fees) ÷ Units. If you only track “unit price,” you are flying at night with sunglasses.

Hidden-Cost Checklist

Pre-production:

- Pattern + grading fees

- Sample rounds (how many included?)

- Size set sample cost

- Print/embroidery setup (screens, digitizing)

- Lab dips / color approvals

Testing and compliance:

- Fabric tests (shrink, colorfast, pilling, flammability if needed)

- Product safety testing (market-specific)

- Certification costs and audits

Production:

- Fabric consumption + waste %

- Trim MOQs and overage cost

- Rework policy and reject allowance

Quality:

- Inline + final QC plan

- Third-party inspection fees

Logistics:

- Terminal/handling charges

- Fuel/peak surcharges (BAF, etc.)

- Insurance

- Customs broker fees

- MPF/HMF (if U.S. import)

Money and risk:

- Currency risk (what FX rate is assumed?)

- Bank fees (wire fees, LC fees)

- Paymnt terms (deposit and balance timing)

Final Reality Check (Conclusion)

Hidden costs in garment manufacturing are rarely “mystery fees.” They usually appear when the quote doesn’t define the full scope, the quality standard, or who pays for what. Once you plan for pre-production, testing, waste, trim MOQs, quality control, and logistics, your “unit price” becomes a true landed cost you can trust. The goal is not to eliminate every extra cost, but to make them predictable, budgeted, and negotiated upfront. Use a detailed costing sheet, confirm the Incoterm, lock a sampling and testing plan, and put your QC rules in writing (AQL, inspection steps, rework responsibility). When you run production with clear terms and transparent partners, you protect your margins, reduce delays, and avoid the painful surprise of paying twice for the same order. If a factory is “cheapest,” it may be because:

- they excluded key items,

- or they plan to charge later,

- or they are cutting corners you will pay for later.

Low unit price can be a decoy. Clear scope is profit.

FAQs About Hidden Costs in Garment Manufacturing

In Short, What do “hidden costs” mean in garment manufacturing in Vietnam?

Hidden costs are expenses outside the factory’s quoted unit price that together form your true landed cost. They include pre-production development (patterns, grading, sampling), lab testing and certification, extra fabric waste, trim MOQs and leftover inventory, third‑party inspections and rework, and logistics surcharges, duties and port fees. These items often arrive after the quote because the quote covered only manufacturing, not the full scope needed to ship compliant, finished product to your market.

Why do hidden costs appear even when the factory quote looks competitive?

Most factories price what you explicitly ask for. If your RFQ does not define sampling rounds, testing requirements, waste assumptions, trim MOQs, QC rules, or the Incoterm, the factory will not include those charges. The result: extra invoices when gaps in scope are filled. The fix is to convert a simple quote into a detailed costing map that assigns responsibility and lists quantities, tests, and processes up front.

What are pre-production development costs and how should I control them?

Pre-production costs cover pattern making, grading, tech‑pack cleanups, and multiple sample rounds. Many factories offer a “free first sample” but charge for revisions, and most styles need several fit changes. To control this: define a sampling schedule and payment terms in writing (number of prototypes, who pays for revisions, lead times), include development line items in the costing sheet, and decide whether patterns/grading are charged as one‑time fees or amortized across the order.

How do trim MOQs create hidden inventory costs, and how can I avoid them?

Trim suppliers (buttons, zippers, labels, hangtags) often have minimum order quantities that exceed your garment order. If a custom zipper MOQ is 10,000 pcs but your order is 1,000 garments, you pay for surplus trim inventory that ties up cash. To avoid this, choose standard trims with lower MOQs, negotiate “MOQ overage cost” or shared inventory arrangements up front, ask the factory to quote trim MOQ implications, or pool trims across styles/orders to spread the cost.