Polypropylene fabric gives you a lightweight, moisture-repellent material made from thermoplastic resin, valued for chemical resistance and low cost across sportswear, medical and industrial uses; however, you must account for poor heat resistance, UV sensitivity and environmental disposal impacts when specifying it for your products.

What is Polypropylene Fabric?

Polypropylene (often abbreviated PP) is a synthetic thermoplastic polymer belonging to the polyolefin family. When this polymer is turned into textile form, we call it polypropylene fabric either in woven, knitted or non-woven form. In simple terms: polypropylene fabric is made from PP resin (the same raw plastic used in many packaging and industrial parts) that has been spun or formed into fibres or sheets, and then processed for textile uses. It has some distinctive features that set it apart from polyester, nylon or cotton.

| Property | Description |

|---|---|

| Density / Weight | Very low among synthetics → lightweight fabrics |

| Moisture behaviour | Wicks/lets sweat pass through, non-absorbent |

| Thermal insulation | Good for cold gear due to low conductivity |

| Chemical resistance | Resistant to many acids/alkalis, inert polymer backbone |

| Dyeing / finishing | Difficult – needs special treatments or pigmented fibre |

| Thermoplastic behaviour | Lower melting point – process care needed |

| UV / outdoor durability | More vulnerable unless stabilised |

| Environmental profile | Derived from fossil feedstock; recycling less common |

How Polypropylene Fabric Is Made

The process starts with turning petroleum-based propylene gas into polypropylene resin through controlled polymerisation. Manufacturers melt this resin and shape it into fibres, films, or non-woven sheets depending on the final use. Since the polymer melts at a lower temperature than other synthetics, careful heat control is important during production. These fibres are then bonded, woven, or knitted to create different types of polypropylene fabrics.

Polymer Production

- The basic monomer is propylene (C₃H₆), derived from petroleum or natural gas feedstocks.

- Through chain-growth polymerisation (often via Ziegler-Natta or metallocene catalysts), propylene is converted into polypropylene resin (long polymer chains).

- The resin is pelleted, combined with stabilisers, fillers or additives as needed.

Fibre / Fabric Formation

Once you have polypropylene resin, you can convert it into fabric in a few ways:

- Spun or extruded fibres: Melt the resin, extrude it into filaments or staple fibres, then draw, cut or spin. (Less common than for polyester/nylon.)

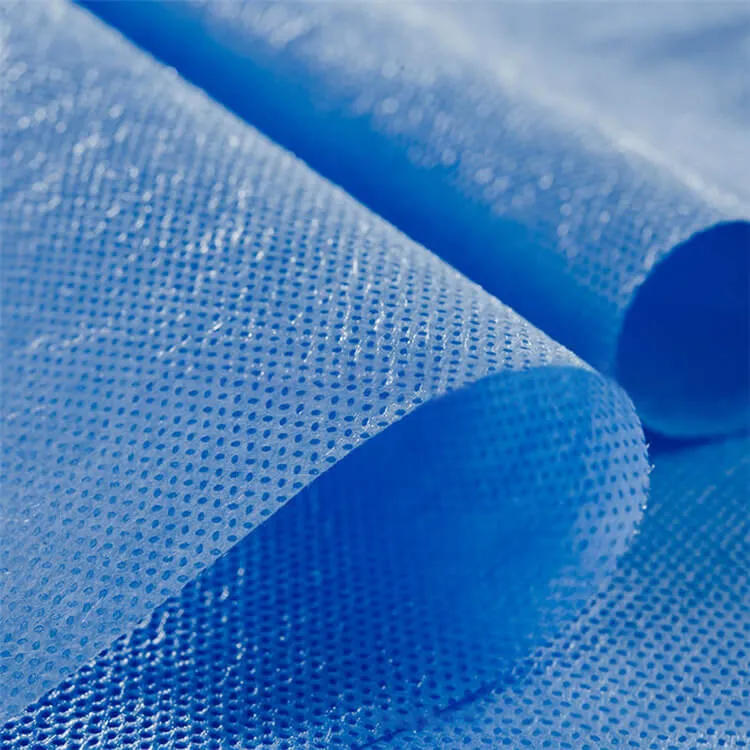

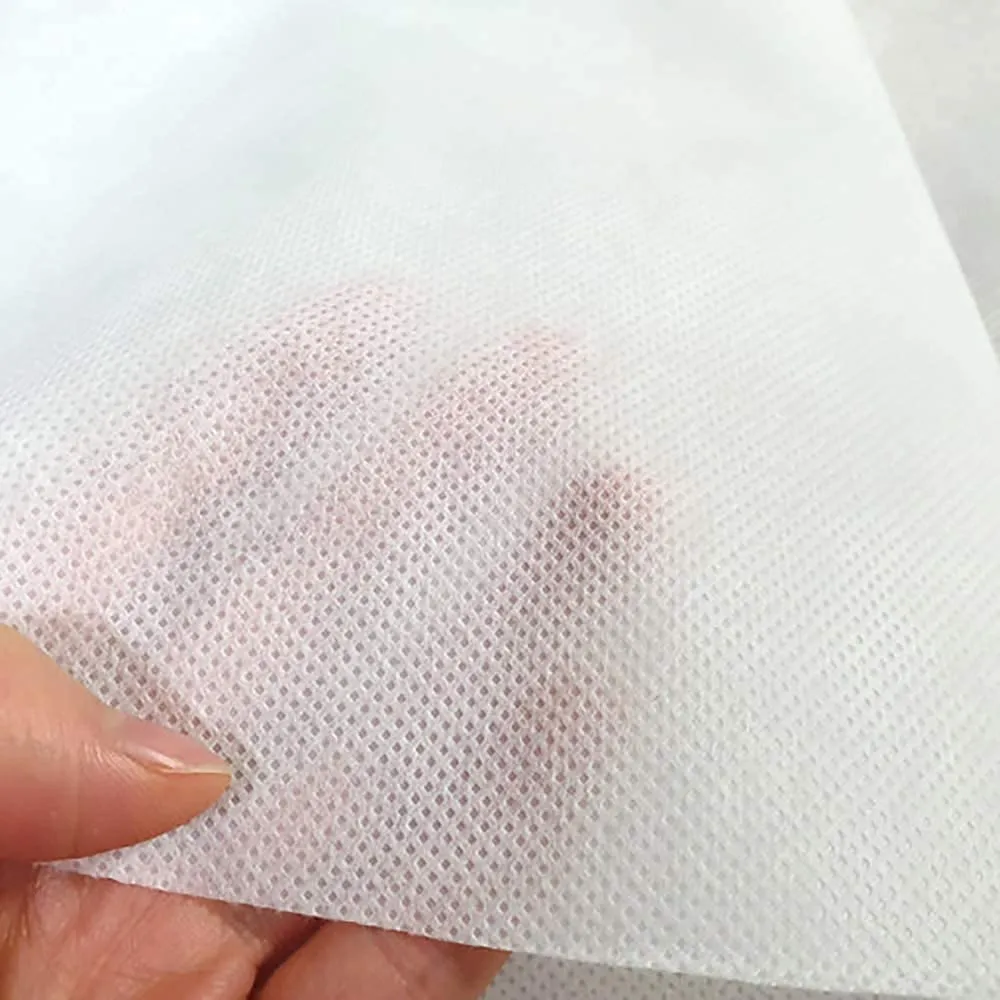

- Non-woven formation: In many cases, polypropylene fabric is non-woven meaning the fibres are laid out in a web and bonded rather than woven or knitted.

- Woven or knitted fabrics: Some PP fibres are woven or knitted into fabrics, though dyeing and finishing are more restricted with PP.

Processing & Finishing

- Since polypropylene has a relatively low melting point compared to some synthetics, processing temperatures must be controlled (to avoid melting, distortion).

- Dyeing is challenging: PP fibres are hydrophobic and resist absorbing dyes. Often they are pigmented at the melt (dope-dye) rather than dyed afterwards.

- Fabric finishing (coatings, laminates, treatments) may be limited because adhesion to PP surfaces is more difficult (e.g., latex or epoxy don’t stick well).

Types of PP Polymer for Textiles

- Homopolymer polypropylene: A simpler PP, but less used in high-end textile fibers due to rigidity.

- Copolymer polypropylene: Mixed with ethylene or other monomers to improve flexibility, impact resistance.

- Fibre grades tend to use those versions that optimise properties for textile use (lighter weight, good wicking).

Properties of Polypropylene Fabric

Polypropylene fabric is known for being incredibly light, fast-drying, and resistant to many chemicals. Its fibres push moisture away instead of absorbing it, helping the wearer stay dry and comfortable. The material also offers good insulation because it transfers heat slowly. However, it has limits too, such as weaker dyeing ability, lower heat resistance, and sensitivity to sunlight unless treated. Here are the major attributes and also limitations of polypropylene fabric, particularly in the context of garment/textile use.

Advantages:

- Lightweight: PP has one of the lowest densities among synthetic polymers (approx. 0.895–0.93 g/cm³) which helps make very lightweight fabrics.

- Excellent moisture transfer / hydrophobic: PP fibres won’t absorb moisture; instead moisture (sweat) passes through and can evaporate quickly. That makes them good for base layers or performance garments.

- Low thermal conductivity: Because of its structure, PP has lower thermal conductivity than many synthetics, which can make it more comfortable in colder conditions.

- Resistance to many chemicals / acids / alkalis: PP is non-polar and chemically inert in many contexts, so fabrics can be used in more demanding environments.

- Abrasion / insect / pest resistance: The polymer nature means fewer issues with mildew, pests, insects (compared to natural fibres).

Limitations / Considerations:

- Dyeing difficulty / colour limitations: Because PP is hydrophobic and non-polar, dyeing it is harder. Usually colour is added during fibre production (pigmented) rather than dyed afterward.

- Lower melting point / thermal sensitivity: PP melts at a relatively low temperature (approx 130-171 °C depending on crystallinity) which means high-temperature washes or finishes risk damage.

- UV degradation: PP is susceptible to ultraviolet (UV) damage unless stabilised; outdoor exposure can degrade it more quickly than some other synthetics.

- Odour retention: In intimate garments (next-to-skin use) PP may retain body odours–a known issue especially with undergarments.

- Environmental concerns: Being fossil-fuel derived, non-biodegradable (in standard form), and less recycled than some plastics, careful attention needed if aiming for sustainability.

Where (and Why) Polypropylene Fabric Is Used

This fabric appears in many industries because it is strong, clean, and economical to produce. In clothing, it is often used for base layers, socks, and outdoor gear that need quick-drying performance. Outside apparel, it is common in medical masks, filters, shopping bags, and geotextiles. Its mix of durability and low weight makes it a popular choice for both disposable and long-lasting products.

Garment / Apparel Use

- Base-layer / thermal underwear: Because of the lightweight and moisture-transfer properties, PP is used for garments worn next to the skin, especially in cold-weather or performance contexts.

- Sports/training wear: Also for sweat-wicking layers, though it has been somewhat superseded by newer polyester blends.

- Undergarments & socks: In some cases, though odor retention is a factor to manage.

- Outdoor utilitarian gear: Tents, backpacks, ripstop fabrics (PP content) where weight and durability matter.

Non-Apparel Textile Use

- Non-woven fabrics: Many use-cases: filters, medical disposables (masks, gowns) because PP non-woven webs are common.

- Packaging / bags / tarpaulins: Woven PP fabrics (often for sacks, geotextiles) thanks to low cost, durability.

- Upholstery / carpet / mats: PP used in carpets, mats, upholstery for stain/soil resistance and colourfastness.

Why Choose PP Fabric in Your Supply-Chain Context

For your garment operations/supply-chain vantage point:

- If you need ultra-lightweight layers (e.g., for export sportswear or cold-weather apparel), PP offers a viable option.

- For cost-sensitive heavy-duty fabrics (bags, sacks, geotextiles) PP may be more economical than other synthetics.

- If your export customers emphasise durability, chemical resistance or easy-care attributes, PP brings value.

- But if colour variety, high dyeability, premium finish, or eco-profile are priorities, you’ll need to weigh PP’s limitations (dyeing, finishing, environmental).

Conclusion / Final Words

In summary: polypropylene fabric is a specialized synthetic textile option. It offers compelling advantages (lightweight, moisture-transfer, chemical resistance) that make it useful in certain apparel and industrial applications. At the same time, it presents challenges (dyeing, finishing, environmental footprint) which you must manage carefully especially in a garment / supply-chain context like yours where customer demands, export standards, sustainability and performance all matter. Before selecting PP for a product line, especially for an apparel export scenario, you’ll want to weigh:

- Will the performance / cost benefits outweigh the dye/finish limitations?

- Can you source textile-grade PP with the right specifications and finish treatments?

- How will customers view the fibre choice from a sustainability/marketing viewpoint?

- Are processing and care instructions aligned with your production setup and user use-cases?

FAQs About Polypropylene Fabric

What is polypropylene fabric and how does it differ from polyester, nylon, or cotton?

Polypropylene fabric is a textile made from polypropylene (PP) resin, a thermoplastic polyolefin. It can be produced as woven, knitted or non-woven material. Compared with polyester and nylon, PP is lighter, has lower moisture absorption (it pushes moisture away rather than wicking by absorption), and offers better chemical resistance. Versus cotton, PP is much faster-drying, less absorbent and more dimensionally stable, but has lower dye uptake and different thermal behavior.

How is polypropylene fabric manufactured from raw materials to finished textile?

Manufacturing begins with polymerisation of propylene into polypropylene resin. The resin is melted and processed into fibres, films or non-woven sheets by melt-spinning, extrusion or bonding methods. Fibres are then drawn, textured if needed, and converted into yarn for weaving or knitting, or bonded into non-woven webs. Careful heat control is required because PP has a lower melting point than many other synthetics; finishing steps can include calendaring, lamination, coatings or treatments for UV or flame resistance

What grades or types of PP polymer are used for textile applications?

Textile producers select PP grades by melt flow rate, molecular structure and additive packages. Typical choices include homopolymer and copolymer grades tailored for spinning performance, strength and elongation. Additives such as UV stabilisers, antioxidants and antistatic agents are often included. Different grades produce fibres suited for non-woven disposables, high-performance knitted sportswear, or durable woven technical textiles.

What are the primary advantages of polypropylene fabric for apparel and industrial uses?

Advantages include very low fabric weight, rapid drying, limited moisture absorption, good chemical and stain resistance, and reasonable tensile strength for its weight. PP provides thermal insulation by transferring heat slowly, offers cost efficiency in production, and is suitable for both disposable products and longer-life technical textiles used in sportswear, medical supplies and geotextiles.

What limitations or handling considerations should garment makers and buyers be aware of?

Polypropylene has limited dyeability with conventional aqueous dyes and requires solution or specific dye systems; it has lower heat resistance and can deform at elevated temperatures, so processing steps like ironing and high-temperature finishing must be managed. Untreated PP is susceptible to UV degradation over time. Environmental concerns include recyclability and lifecycle footprint, so sourcing, end-of-life options and regulatory compliance need attention.

In which apparel and non-apparel products is polypropylene fabric commonly used?

In apparel, PP is used for base layers, thermal underwear, socks, liners and outdoor gear where low weight and quick drying matter. Non-apparel uses include medical masks and disposables, filtration media, shopping bags, geotextiles, furniture components and industrial packaging. Its versatility makes it common across disposable products and durable technical applications.

Why might a garment supply-chain choose polypropylene fabric and what steps should they take before specifying it?

Supply-chains choose PP for weight-sensitive, fast-drying, chemically resistant or low-cost applications. Before specifying PP, assess required performance (dyeing method, UV stability, heat tolerance), select an appropriate polymer grade and finishing treatments, verify supplier capability for consistent melts and fibre formation, and plan testing for colour fastness, tensile performance and regulatory standards. Mekong Garment Vietnam can advise on grade selection, finishing options and production controls to meet export and performance needs.