Spun vs. Core-Spun Polyester Just as you specify threads for production, spun polyester is the industry workhorse you’ll choose for your production of light to medium fabrics because it reduces needle heat, offers cost-effective performance and resists chemical degradation, maintaining colorfastness through industrial laundering; however, using it on heavy denim or workwear is a dangerous mistake that can cause seam failure, so you should reserve higher-tenacity core-spun or filament threads for high-stress applications.

About Spun Polyester and Benefits

Definition and Characteristics

You will find that spun polyester serves as the industry workhorse due to its unique construction. It is created by spinning short staple fibers together, resulting in a hairy surface that mimics the texture of cotton while retaining the resilience of synthetic polymer. This fuzzy exterior provides excellent lubrication characteristics, effectively reducing needle heat during high-speed sewing operations. It is significantly more cost-effective than core-spun options, yet it maintains high color fastness and resistance to chemical degradation, ensuring your garments withstand repeated industrial laundering.

=> Related Article: 5 Types of Thread Structures: Spun Polyester, Core-Spun, Continuous Filament, Monofilament….

Manufacturing Process

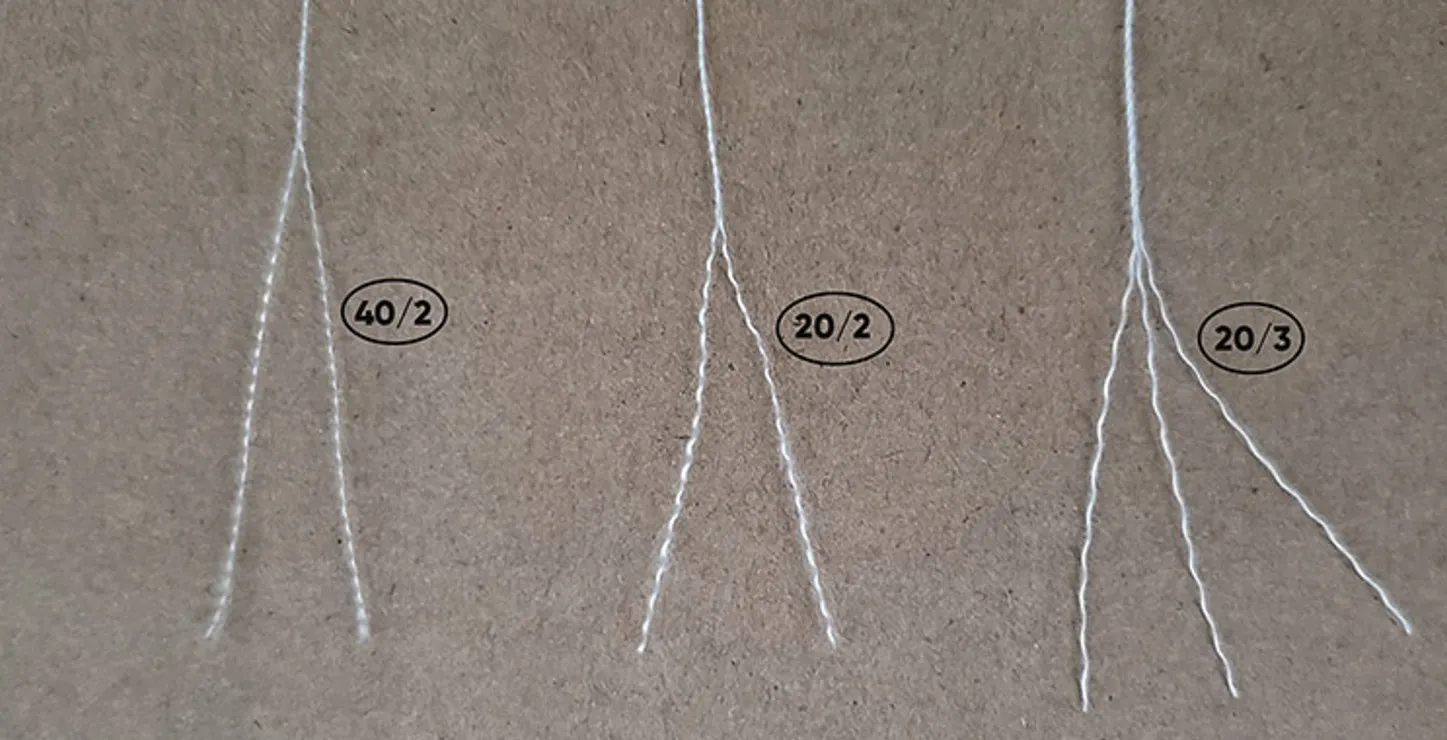

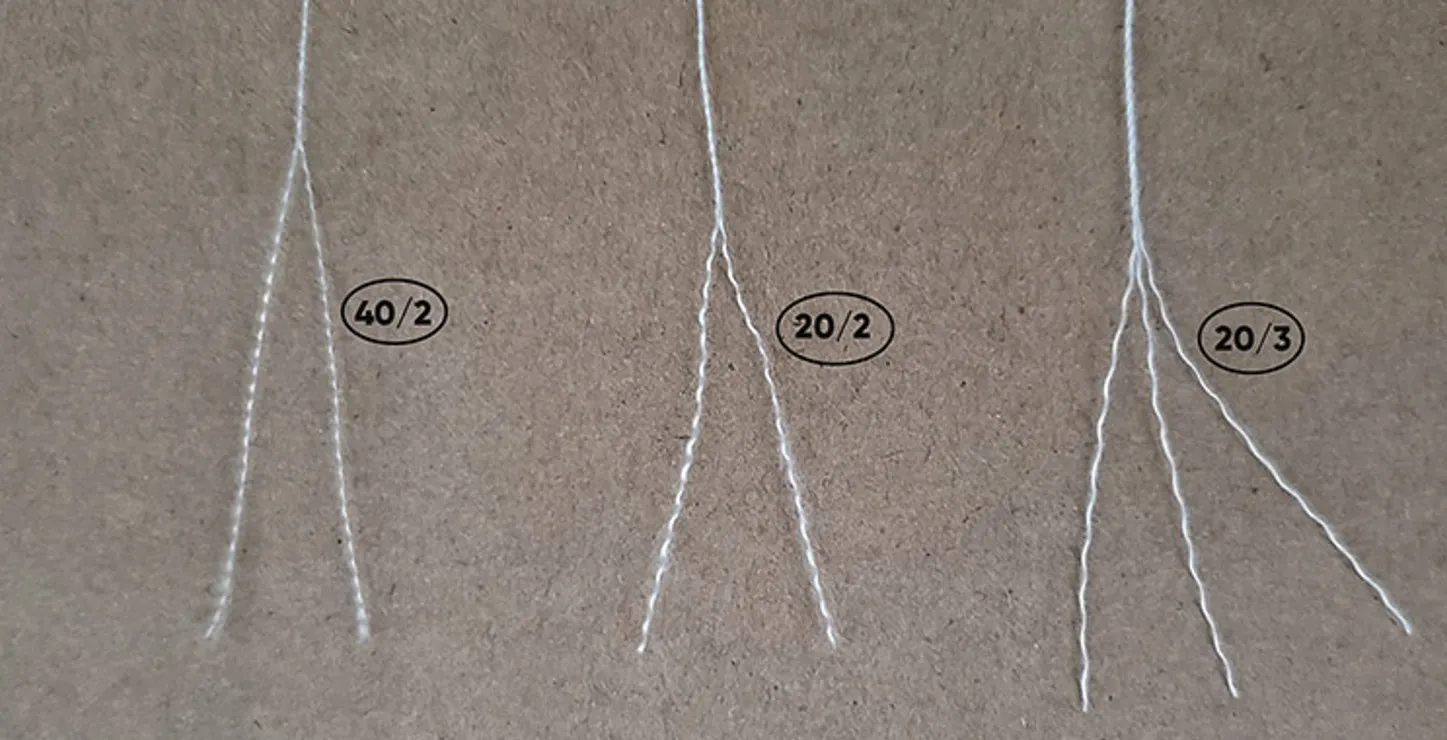

The flow begins with staple fibers (typically 32-38 mm) that are drawn, carded and combed, then spun-usually ring-spun or open-end-into yarns; you’ll see twist adjusted to trade off strength versus hairiness, followed by heat-setting and lubrication to stabilize dimensions and improve sewability. Ring-spinning and heat-setting largely determine final seam performance. Operational choices matter: you can specify solution-dyed staples for superior colorfastness or post-spin dyeing for flexible shades, and common apparel threads sit around 20-40 tex.

Benefits of Spun Polyester

- Cost-Effectiveness: You can cut thread spend significantly by specifying spun polyester: typical material cost is about 20-40% lower than core-spun for equivalent ticket sizes, and you’ll preserve premium lines for stress points. In Vietnam production runs where spun polyester covers roughly 80% of conventional garments, using it for side seams, hems and overlocking lowers per-piece cost while keeping overall defect rates low when machines are tuned correctly.

- Durability and Resilience: For light-to-medium apparel you’ll get reliable seam life because spun polyester resists abrasion and fiber migration; however it is physically weaker than core-spun, so you often increase one ticket number to match strength. Your operators will also benefit from reduced needle heat and smoother high-speed sewing due to the thread’s hairy surface. Field data from batch productions show spun polyester maintaining seam integrity through roughly 30-50 commercial launderings on shirts and blouses, with low fraying on overlocked edges. You should avoid it on heavy-duty workwear or safety garments where filament or core-spun tensile strength is required, and instead reserve spun polyester for applications where balanced cost and holding power matter.

- color fastness and Chemical Resistance: You’ll rely on spun polyester when color retention matters: it accepts disperse-class dyeing and exhibits high color fastness to industrial washing and dry cleaning, outperforming many natural-fiber threads. That chemical resistance makes it suitable for garments exposed to detergents, enzymes, and moderate alkalis used in commercial laundries. In production trials across Vietnamese OEM lines, matching polyester-dyed threads showed minimal shade change and negligible dye transfer after dozens of industrial cycles, and they tolerate routine bleaching agents better than cotton-based threads. Use spun polyester when you need stable color under repeated processing and retail care instructions.

=> Related Article: The Best Fabric for Hoodies: Top 10 Materials You Should Know

Applications in Garment Production

Due to its versatile nature, you should utilize this thread primarily for light to medium-weight fabrics. It performs exceptionally well on woven shirts, blouses, and knit tops where extreme seam strength is not the primary requirement. Manufacturers frequently rely on it for standard seaming and overlocking operations in mass production environments. However, applying this thread to heavy-duty denim or workwear is a dangerous mistake that often leads to seam failure under stress.

When sourcing for children’s wear or budget-friendly fashion lines, this structure offers the perfect balance between durability and cost. The protruding fibers help the thread grip the fabric, creating a stable seam that resists slippage on slick synthetic materials. While it lacks the high tensile strength of continuous filament, it provides adequate holding power for general apparel assembly, making it the standard specification for roughly 80% of conventional clothing items produced in Vietnam. You can confidently specify it for side seams, hems, and topstitching on garments that do not require high elasticity.

Comparison with Other Thread Types

Unlike continuous filament which appears glossy and smooth, spun polyester possesses a matte finish that blends seamlessly with natural fiber fabrics. It is physically weaker than core-spun threads of the same size, meaning you must often use a thicker ticket number to achieve comparable strength, which inevitably creates a bulkier seam profile. While core-spun threads utilize a filament core for added tenacity, spun polyester relies entirely on the friction and twist of staple fibers. This makes it less suitable for automated multi-directional sewing where tension varies rapidly. However, for standard straight stitching, the difference in breakage rates is often negligible if your machines are set correctly, allowing you to save on raw material costs by reserving premium threads only for stress points.

=> Related Article: How to Get a Great T-Shirt Print Even If You Can’t Design

| Feature Comparison | Spun Polyester Details |

| Surface Texture | Fuzzy / Cotton-like (Matte finish) |

| Relative Cost | Lowest (Most economical option) |

| Tensile Strength | Moderate (Lower than Core-Spun) |

| Needle Heat Resistance | High (Due to lubrication) |

| Ideal Application | General Wovens & Knits |

- Core-Spun Threads: Offer superior strength per diameter size but come at a higher premium.

- Continuous Filament: Provides a glossy look and high tenacity but can cause seam puckering on light fabrics.

- Spun Polyester: Delivers the best cost-to-performance ratio for standard, non-stretch garments.

Recognizing the trade-off between price and performance allows you to optimize your production budget without sacrificing garment integrity.

Spun vs. Core-Spun Polyester

- Spun: Shorter fibers spun into yarn; gives a natural look, good for general use.

- Core-Spun: Continuous filament polyester core wrapped with polyester fibers; extra strong, smooth, with a consistent look, best for heavy-duty applications.

Final Word / Conclusion

Spun polyester thread is a smart, reliable choice for everyday garment sewing. It offers a good balance of strength, smooth sewing, stable color, and affordable cost. Because it behaves much like cotton but lasts longer, many factories use it for most basic seams on light to medium fabrics. In short, if you need a thread that runs well on machines, holds up in regular washing, and keeps production costs under control, spun polyester does the job well. For higher stress seams or heavy fabrics, you may need stronger options, but for daily apparel production, spun polyester remains a trusted and practical solution.