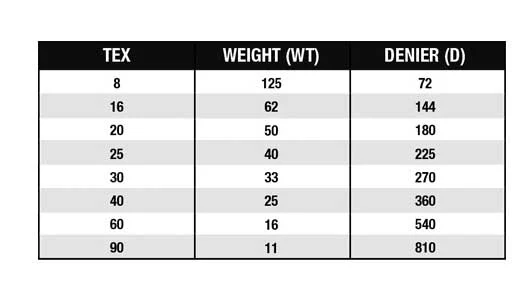

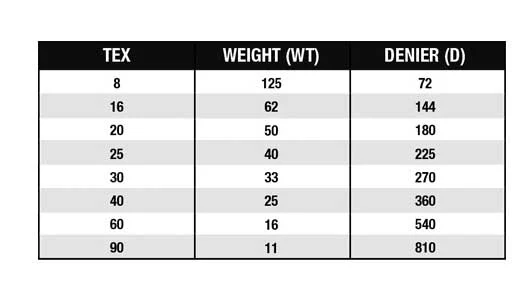

The Tex system provides a consistent, direct method to quantify thread mass, eliminating the confusion often caused by variable count systems. Simply put, the Tex value represents the weight in grams of 1,000 meters of thread. This universal standard allows you to compare different thread types regardless of their material composition. A higher Tex number indicates a heavier, thicker thread, while a lower number signifies a finer, lighter strand. This direct correlation makes it the preferred metric for technical specifications in modern garment manufacturing, ensuring you know exactly how much bulk you are adding to a seam.

=> Related Artiicle: Spun Polyester Thread: Best Cost-To-Performance Ratio for Standard, Non-stretch Garments.

Comparison of Thread Thickness:

Common Tex Value Classifications

Comparing thread thickness becomes straightforward when you utilize Tex values as your primary guide. You will typically encounter a range of numbers from Tex 18 for fine fabrics up to Tex 80 or higher for heavy-duty applications. Small increments in these numbers represent tangible differences in physical bulk and needle compatibility. Recognizing these distinctions ensures you do not accidentally pair a heavy denim thread with a delicate silk blouse, which would cause puckering or fabric damage. Your ability to distinguish between these values is fundamental to achieving the correct aesthetic finish.

=> Related Artiicle: 5 Types of Thread Structures: Spun Polyester, Core-Spun, Continuous Filament, Monofilament….

| Thread Category | Tex Range |

| Fine / Lightweight | Tex 16 – Tex 24 |

| Medium / General Purpose | Tex 30 – Tex 40 |

| Heavy / Heavy Duty | Tex 60 – Tex 105+ |

Detailed Application by Tex Value

To visualize this better, consider that a Tex 24 thread is standard for lightweight shirts, offering a balance of strength and unobtrusiveness. As you move up the scale, a Tex 40 serves as the workhorse for general apparel like trousers and knitwear, providing the necessary bulk to fill the needle hole without distorting the fabric. At the heavier end, Tex 80 or 105 is reserved for denim jeans and leather goods, where the thread must be prominent and withstand significant abrasion. Understanding these specific benchmarks allows you to predict how the thread will sit on the fabric surface before you even begin sampling.

| Tex Value | Typical Application |

| Tex 18 | Overlocking, blind stitching, very fine fabrics (silk, lining). |

| Tex 24 | Lightweight wovens, dress shirts, blouses. |

| Tex 40 | General sewing, casual wear, trousers, workwear. |

| Tex 60 | Heavy workwear, denim jeans, light leather. |

| Tex 80 | Heavy denim, leather goods, decorative topstitching. |

Impact of Tex on Thread Selection

Selecting the correct Tex value directly dictates machine performance and seam integrity. If you choose a thread with a Tex value too high for your fabric, you risk seam puckering and needle heat damage because the thread displaces too much yarn in the fabric weave. Conversely, a Tex value that is too low may result in snapped threads and weak seams that fail under tension. Your choice must align with the fabric weight to ensure the machine feeds smoothly and the stitch formation remains balanced throughout the production run.

=> Related Article: 12 Common Types of Industrial Sewing Threads Used in the Garment Industry

Beyond basic strength, the Tex value dictates your required needle size. A thicker thread (higher Tex) demands a larger needle eye to pass through freely; using a small needle with high-Tex thread causes shredding and frequent breakage due to friction. Additionally, the thread’s mass affects tension settings. You will need to adjust your machine tension to accommodate the diameter of the thread to prevent loops on the underside of the fabric. Matching Tex to needle size (e.g., Tex 40 with a size 90/14 needle) is the single most effective step to prevent costly downtime on the production line.

Thread Construction Labels Mean (e.g., 40/2, 60/3)

When you encounter specifications like “40/2” or “60/3,” the first number represents the yarn count (fineness), while the second indicates the ply, or how many single filaments are twisted together. A higher second number generally signals greater strength because more strands reinforce the thread structure. For instance, a “60/3” thread is formed by twisting three strands of size 60 yarn, making it stronger and more robust than a “40/2” option, even if the individual filaments are finer. This construction directly impacts the thread’s physical diameter and its ability to withstand abrasion.

- In a label like “40/2”: the “40” refers to the fineness (single-filament filament count if spun singly), and the “2” refers to two filaments twisted together (“plies”).

- Similarly “60/3” means three filaments of tex-60 (or similar base) twisted together. The twisting increases overall thread strength and thickness relative to a single filament.

- So a multiply thread gives more strength, durability which matters for heavy fabrics or high-stress seams.

Final Word / Conclusion

Choosing the right thread thickness is not just a technical detail it is one of the most important decisions in garment production. When you understand Tex values and how they relate to thread strength, durability, and appearance, you can match every seam to the fabric it supports. This helps your products look cleaner, last longer, and pass quality checks with fewer issues. Whether you are sewing delicate shirts or heavy-duty workwear, using the proper Tex level gives you more control and more confidence in your production. In the end, good thread choice is good manufacturing and it always shows in the final garment.