The Acceptable Quality Limit (AQL) is one of the most widely used tools in garment quality control. Brands, factories, and third-party inspection companies rely on it to decide whether a production batch should pass or fail. It sets a clear limit for how many defects are allowed in a sample before the entire lot is rejected. Because it’s simple and objective, AQL is the global “language” between buyers and manufacturers.

=> Read More: Should Use Third-Party Final Inspections When Ordering Garments in Vietnam?

What Acceptable Quality Limit (AQL) Means?

Overall, the number of defects allowed depends on what the supplier and buyer agree to and how much risk they are willing to accept. Items that could affect health or safety always use a lower AQL limit. Once both sides set the AQL standard, it becomes the fixed reference for all inspections and defines how many defects are acceptable in each shipment. AQL tells you the maximum percentage of defects that can be accepted in a shipment.

=> Read More: Defect Categories in Garment Inspection (Critical / Major / Minor)

In apparel production, defects are grouped into three levels:

1. Critical Defects (AQL – Acceptable Quality Limit 0%)

Critical defects are the most serious issues in garment inspections. They can make a product unsafe or completely unusable, so even one mistake is enough to fail a shipment. This factor sets the highest level of control and protects consumers from harm. Examples:

- Sharp metal objects left inside garments

- Flammable trims violating safety laws

- Wrong fiber content label that violates regulations

AQL for critical defects is almost always 0% — any critical defect means automatic rejection.

2. Major Defects (Common AQL: 2.5%)

Major defects affect how the product works, fits, or looks. These issues may not be dangerous, but most customers will reject the item if they see them. This factor helps keep quality stable and protects the buyer’s experience. Examples:

- Open seams

- Broken stitching

- Large stains

- Wrong measurements outside tolerance

For many buyers, AQL 2.5 is the standard pass/fail limit for major defects.

3. Minor Defects (Common AQL: 4.0%)

Minor defects are small issues that do not affect the way the garment is worn. Most people will not notice or care about them. This factor helps factories manage small variations without slowing down production. Examples:

- Slight misalignment of pocket

- Tiny stains under tolerance

- Small wrinkles

Typical AQL for minor defects is 4.0.

How AQL Works During Garment Inspection

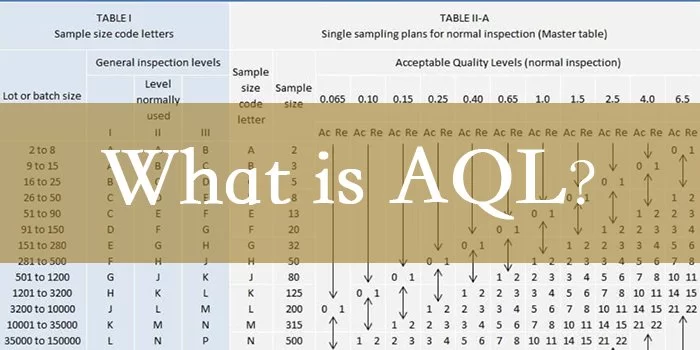

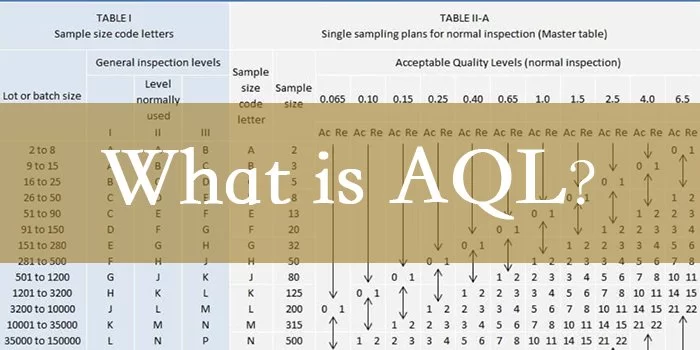

Inspectors don’t check 100% of the pieces. Instead, they use a sampling plan (most often ANSI/ASQ Z1.4 or ISO 2859-1) to select a specific number of units from the full batch.

Step-by-Step Process

- Choose Inspection Level – Most apparel brands choose “General Inspection Level II” (GII).

- Determine Sample Size – Based on carton quantity, production lot size, and inspection level.

- Check Each Sample – Inspectors look for critical, major, and minor defects.

- Compare Defect Count With AQL Table – Each sample size has an “Accept” and “Reject” number.

- Decision If defects stay within allowed limits → PASS !! If defects exceed limits → FAIL

Example (Using Your Data)

For AQL 2.5 on major defects: If the inspector finds 11 or more major defects in the sample, the batch fails.

Benefits of AQL in Garment Manufacturing

AQL plays a big role in keeping quality predictable when factories produce large orders. It gives both buyers and manufacturers a shared standard to follow. This factor helps reduce disputes, lower costs, and improve customer trust.

- Ensures Consistent Quality Across Large Orders: AQL keeps quality stable even when producing thousands of pieces across multiple lines or factories.

- Protects Both Buyer and Manufacturer: Buyers gain confidence in the product quality. Factories have a clear objective standard to follow, reducing disputes.

- Helps Control Production Cost: By catching problems early, factories can avoid expensive rework, fabric waste, and shipment delays.

- Creates a Common QC Language: AQL is a universal standard. Whether working with the U.S., Europe, Japan, or Korea, the AQL system remains the same.

Typical AQL Standards Used in the Garment Industry

Different product types and brand levels use different AQL limits. Understanding these common standards helps factories prepare for buyer expectations. This factor explains what levels are used most often in the garment world. Most global brands follow the combinations below:

| Defect Type | Common AQL Level | Meaning |

|---|---|---|

| Critical | 0.0 | Zero tolerance |

| Major | 2.5 | Visible functional or appearance issues |

| Minor | 4.0 | Small issues that do not affect use |

- Some high-end brands use: AQL: 1.0 / 1.5 / 2.5

- Fast-fashion brands often use: AQL: 2.5 / 4.0 / 6.5

Final Words / Conclusion

AQL is the backbone of garment quality control. It provides a fair, consistent, and measurable method to judge whether a shipment meets the buyer’s expectations. By using AQL the right way especially with good in-line QC, measurement control, and defect tracking factories can reduce rework, improve lead times, and keep quality stable across every production run.

FAQs About AQL – Acceptable Quality Limit

What is AQL in simple terms?

AQL is a limit that tells you how many defects are allowed in a sample before a shipment is rejected. Instead of checking every piece, inspectors look at a selected group and use that result to judge the whole lot. If the number of defects in the sample stays within the AQL limit, the order passes. If defects exceed the limit, the order fails. This system keeps inspections fast, fair, and predictable.

Does AQL measure the defect rate of the whole production?

No. AQL does not measure every item in the batch. Instead, it uses a small sample to estimate the quality of the entire order. This works because AQL follows statistical rules. It saves time and cost while still giving a reliable picture of overall quality. Even though it’s not perfect, it is trusted because the sampling method is consistent worldwide.

Who decides the AQL level?

Both the supplier and the buyer agree on the AQL before production starts. The choice depends on product type, market expectations, and safety concerns. For example, baby clothing or protective wear may need a stricter AQL because the risk is higher. Fast-fashion items may use a more flexible AQL. What matters is that both sides approve the level in advance to avoid disputes later.

Why is AQL 0% for critical defects?

Critical defects are not allowed because they can harm the customer or violate safety laws. Even one critical defect can cause injury, lead to returns, or cause legal issues for the brand. Examples include: Needles or sharp objects left in the garment, Highly flammable fabrics in kidswear, Incorrect fiber content that violates regulations! Because of the risk, the limit is always zero.

Is a lower AQL always better?

No. A lower AQL means fewer defects allowed, but it also increases pressure on sewing lines, QC teams, and production schedules. It may raise labor cost, slow down output, and force more repairs. AQL must match the product’s needs. For example, a medical gown requires a lower AQL than a basic T-shirt. The goal is to choose the right level—not the strictest level

Can AQL prevent all defects from reaching customers?

AQL reduces risk, but it cannot guarantee that every single defective piece is caught. It only checks a sample, not every unit. However, when combined with in-line QC, measurement checks, and final audits, AQL greatly lowers the chance of customers receiving faulty items. It’s a balance between quality, speed, and cost.

Do all garments in the batch get checked?

No. Inspectors check only a small sample based on lot size and inspection level. For example, a lot of 2,000 pieces may require only 125 samples. This method avoids the time and expense of checking thousands of units while still giving reliable results. The sample size is chosen using ISO 2859-1 or ANSI/ASQ Z1.4 tables.

Are measurements included in AQL inspection?

Yes. Measurement checks are a key part of AQL inspections because they affect fit and comfort. Wrong measurements are usually classified as major defects. Inspectors pick random pieces and measure key points like chest, waist, length, sleeve, and hip. If too many items fall outside tolerance, the lot can fail even if visual defects are fine.

Can AQL change during production?

AQL can change only if both the buyer and supplier agree. Once set, it becomes the standard for all inspections. Changing it midway can create confusion or disputes. Buyers might adjust AQL only when dealing with extremely sensitive products or new suppliers who need stricter controls.