Canvas fabric is one of the most trusted materials in the textile world known for its strength, versatility, and natural beauty. Woven tightly from thick cotton, linen, or hemp yarns, it creates a dense and durable surface that can stand up to years of use. From ship sails and tents in ancient times to today’s jackets, tote bags, and home décor, canvas has proven its value across centuries. Its simple plain-weave structure may look ordinary, but it hides remarkable toughness and flexibility. Whether left natural, waxed for weather resistance, or dyed in rich colors, canvas remains a timeless fabric that blends practicality with style a true workhorse of modern manufacturing and design.

What is Canvas Fabric?

Canvas is a strong, tightly woven fabric known for its durability and heavy feel. It’s made using a plain weave structure meaning each yarn crosses over and under one by one which makes it sturdy and long-lasting. In the past, canvas was made from hemp or linen for ship sails and tents. Today, cotton canvas is most common, used for clothes, bags, and home products. Its classic rough texture gives it a timeless and natural look.

- The term canvas refers to a heavy-duty, plain weave (one over, one under) fabric, traditionally made from coarse yarns of natural fibres such as hemp or linen, and more recently cotton (or sometimes blends).

- Etymology: The English word “canvas” comes via Anglo-French canevaz or canevas, derived from the Latin cannapaceus (“of hemp”), ultimately tracing back to Greek κάνναβις (cannabis/hemp).

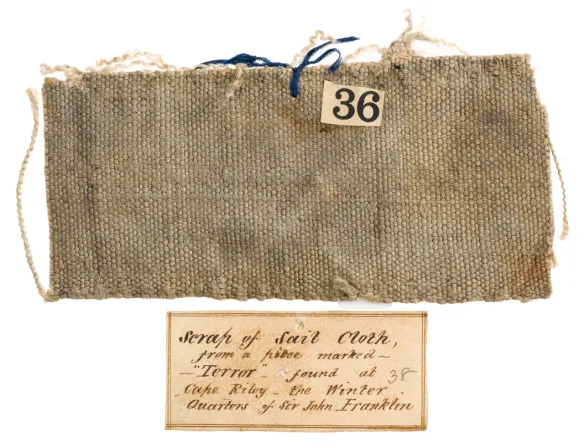

- Historically, canvas was used for sailcloth, tents, painting supports (artists’ canvases), and other applications requiring robustness.

- In modern textile/manufacturing environments, “canvas fabric” commonly refers to a medium-to-heavy weight cotton (or cotton-blend) plain-weave fabric used in bags, apparel (especially workwear/outdoor), upholstery, and industrial goods.

Canvas traces to hemp and linen used for sails and tents during the Age of Sail; by the Renaissance painters shifted from wood panels to canvas for larger oil works, and the 19th‑century Industrial Revolution brought cotton canvas into mass production. You can link the shift to cotton to inventions like the cotton gin (1793), which lowered raw cotton costs and made canvas widely available for upholstery, military gear, and commercial textiles. Artists such as Titian and Rembrandt popularised stretched canvas in the 16th–17th centuries, enabling larger formats, while brands like Filson (founded 1897) built reputations on waxed canvas for outdoor use. You should note that canvas was standard issue in early 20th‑century military tents and gear, demonstrating its long record in demanding applications.

Composition and Weave

The strength of canvas starts from its yarn. It’s usually made with thick cotton, linen, or hemp threads that are tightly interlaced. The plain weave design creates a balanced, dense surface that resists tearing and fraying. While most cotton fabrics use fine yarns for softness, canvas uses coarse yarns for toughness. This simple yet powerful weave gives canvas its signature rugged texture and long life.

Fibres / yarns

- While early canvas was made of hemp or linen, today cotton is the dominant fibre for canvas fabric.

- The yarns used are relatively coarse/strong rather than ultra-fine: in many cases “carded” rather than combed cotton is used, because smoothness isn’t the primary goal durability is.

- Some versions may blend with synthetics (e.g., polyester) or use special finishing for outdoor/industrial uses. Blends or coatings may complicate recycling, dyeing, compliance.

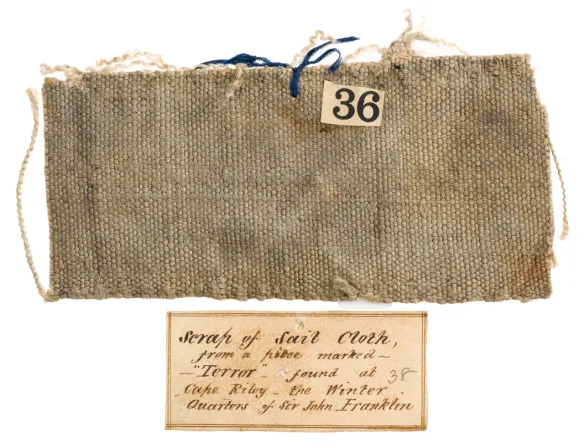

Weave

- The typical weave is a plain weave (warp over-under weft) which gives the textile a dense, tight structure.

- This is in contrast to fabrics like denim, which use a twill weave. The plain weave, combined with thicker yarns, provides opacity, weight and durability.

- There are variants: e.g., “duck” canvas (sometimes written “duck cloth”) refers to a type of canvas with tighter weave or heavier yarns.

Weight & density

- Canvas is often classified by weight (ounces per square yard or grams per square metre). Heavier weight = more robust & use for industrial/outdoor.

- Thread-count for canvas tends to be lower (because yarns are thicker). For example: thread count ~50-100 for many canvas fabrics.

Key Properties Canvas Fabric

Canvas stands out because it’s tough, sturdy, and weather-resistant. Its dense structure gives it great protection from wear, making it perfect for outdoor use. Even without treatment, canvas naturally resists water to some degree, and with coatings, it becomes nearly waterproof. Over time, canvas softens but doesn’t lose its strength, giving it a charming “worn-in” look. These traits make it ideal for both heavy-duty and fashionable uses.

You specify canvas for manufacturing or sourcing, these are the functional attributes you care about:

- Durability / abrasion resistance: The dense weave plus heavy yarns give canvas fabric excellent resistance to wear and tear compared with lighter fabrics.

- Strength / stiffness: It retains shape well, offers support in bags, upholstery, outdoor gear, apparel.

- Water resistance / weather-proofing: Untreated canvas has some natural resistance (due to tight weave), but for outdoor use many canvases are treated/coated (e.g., wax, PVC, other finishes) to increase water-resistance, wind resistance, and durability.

- Texture / appearance: Typically chunkier, more “rustic” or utilitarian in feel compared to fine cottons. That may or may not suit fashion/consumer apparel depending on design.

- Stability: Because of the structure, canvas tends to hold up well in applications that require dimensional stability (tents, bags, upholstery).

- Versatility: Because of its robust nature, canvas can undergo heavy treatments, printing, coatings, and still perform.

- Maintenance / ageing: For user-end (bags, outerwear) canvas acquires a patina, marks, which may add to aesthetic value rather than detract. On the other hand, for apparel you might require pre-wash/shrink control.

- Limitations: Because the yarns are coarse and structure heavy, the hand may be stiffer, less drapey, and the fabric may stretch slightly in use (depending on finishing). Some finishes/coatings may reduce breathability. For lighter apparel applications these factors must be weighed.

Types & Classification

Not all canvas fabrics are the same they vary by fibre, weave, and finish. Cotton canvas is soft and affordable, while linen and hemp versions are stronger and longer-lasting. “Duck canvas” is a smoother, tightly woven version often used for bags and shoes. Waxed canvas offers a vintage, water-repellent surface loved by outdoor brands. Each type serves a unique purpose, from fashion to industrial use.

Types by fibre

- Cotton canvas – the most widespread. More accessible cost, good performance.

- Linen canvas – higher cost, higher durability, smoother hand (preferred for fine art).

- Hemp canvas – very durable, strong, but less common (due to regulatory and cultivation limitations).

- Blended/Synthetic canvas – mix of cotton/linen with synthetics or coatings to enhance certain properties. This becomes more technical and may impact recyclability.

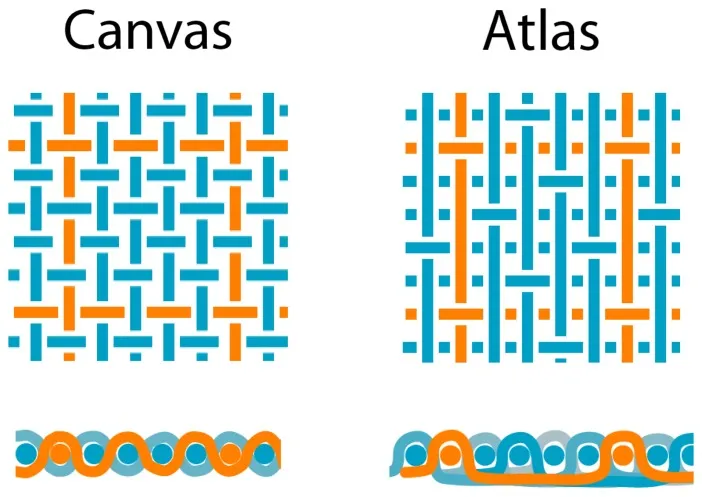

Types by weave / finish / classification

- Plain canvas – standard canvas, with standard weighting and plain weave.

- Duck canvas (duck cloth) – originally the Dutch word doek (cloth), used for tighter/weavier versions of canvas. In practice often used in heavy duty bags, outdoor gear, etc.

- Artist canvas – lighter weight versions of canvas designed for painting (stretched, primed with gesso) rather than bags or apparel.

- Coated / treated canvas – e.g., waxed canvas (for jackets or heritage outerwear), PVC-coated canvas (for tarps, tents) etc.

Weight classification

- Canvas is often sold based on weight. For example, in the U.S. it may be ounces per square yard. A higher ounce means heavier fabric. Some numbering systems run reversed (number 10 lighter than number 4) in certain “number duck” systems.

- For your factory sourcing, you might see spec like “12 oz cotton canvas, plain weave, 60″ wide, uncoated” or “18 oz PVC-coated cotton canvas, 54″ wide”. Specifying width, weight, finish, and fibre is crucial.

Uses & applications

Canvas is one of the most versatile materials ever made. It’s used in clothing, footwear, tote bags, upholstery, and even in tents and sails. In fashion, canvas gives a natural yet durable touch to jackets and shoes. For home decor, it adds a rustic charm to cushions and curtains. Because it’s easy to print and dye, designers love it for creative projects. Given your involvement with garment manufacturing, accessories, export supply chain, the following applications are relevant:

- Apparel / workwear / outerwear: Canvas is used for jackets (especially heritage or outdoor style), pants, vests, and uniforms where durability matters.

- Bags / accessories: One of the largest uses now: tote bags, backpacks, duffels, messenger bags, laptop sleeves. Canvas gives structural body, durability, prints well, supports hardware.

- Footwear / sneakers: Canvas uppers are common in casual sneakers due to the fabric’s structure and printability.

- Outdoor / industrial: Tents, tarps, awnings, sails historically, and modern rugged outdoor gear still use canvas (often coated).

- Home / upholstery / décor: Sofa upholstery, cushion covers, wall coverings, because canvas can handle abrasion and heavier use.

- Artist’s canvas: Stretching over frames for painting (less relevant to garment manufacturing but interesting in the textile eco-system).

In your sourcing context, for a garment factory you might be specifying canvas for bags or outerwear. Key is: choose weight, finish, coating, width, and cost trade-offs based on end use.

Summary / Final Word

In short, canvas fabric is a work-horse material in the textile and garment world: strong, durable, versatile. For your factory, supply-chain and export work, specifying and controlling canvas fabric means paying attention to fibre, yarn, weave, weight, width, finish, coating, and downstream finishing & compliance. Using the correct spec will help ensure product performance (durability, fit for purpose), manufacturing efficiency (cut/sew, machinery), and supply-chain clarity (cost, sourcing lead time, compliance).

FAQs About Canvas Fabric

In Short, What is Canvas Fabric?

Canvas is a strong, tightly woven plain-weave fabric historically made from hemp or linen and today most commonly made from cotton. It has coarse yarns and a dense surface that provide a heavy feel and a rugged texture, originally used for sails and tents and now used for clothing, bags, footwear, and home goods.

How is canvas constructed and what fibres are used?

Canvas is made with thick, durable yarns (cotton, linen, or hemp) interlaced in a plain weave where each yarn passes over and under one at a time. The fibre choice affects hand and strength: cotton offers softness and lower cost, linen and hemp offer greater tensile strength and longevity. Weight and density are controlled by yarn thickness and picks per inch.

What are the key properties of canvas fabric?

Canvas is durable, tear-resistant, and abrasion-resistant due to its dense plain weave and coarse yarns. It provides moderate natural water resistance and becomes highly water-repellent when coated or waxed. Canvas softens with use while retaining structural strength, accepts dyes and prints well, and performs strongly in outdoor and utility applications.

What types of canvas should I know about?

Types vary by fibre, weave, and finish: cotton canvas (soft, affordable), linen/hemp canvas (stronger, longer-lasting), duck canvas (smoother, tightly woven for bags and shoes), and waxed canvas (coated for vintage look and water repellence). Classification also includes differences in weight and finish—uncoated, coated, or laminated—for different end uses.

How does canvas weight and finish affect its applications?

Weight determines suitability: lighter canvas (for apparel and linings), mid-weight (tote bags, upholstery), and heavy-weight (outdoor gear, tents). Finishes and coatings add water resistance, stain repellence, or aesthetic effects (wax, PVC, or acrylic coatings). Choose weight and finish to balance durability, flexibility for cut-and-sew, and cost.

What are the main uses of canvas in garment manufacturing and accessories?

Canvas is used for outerwear, jackets, and workwear; footwear like sneakers and boots; bags and totes; upholstery, cushions, and curtains; and industrial items like tents and sails. In garment factories, canvas is selected for items needing structure and durability; it’s easy to print and dye, making it popular for branded and fashion pieces as well as functional goods.