In modern garment manufacturing, sewing thread is not just a minor accessory. It directly affects seam strength, sewing speed, fabric appearance, and even product lifespan. Among the many thread constructions available today, core-spun thread is one of the most widely used—especially in denim, workwear, and industrial sewing. At first glance, core-spun thread sounds like the perfect solution: strong, smooth, fast, and versatile. But in practice, its performance depends heavily on how it is made, where it is used, and what trade-offs the factory is willing to accept. This article breaks down what core-spun thread really is, how it works, where it shines, and where it quietly fails.

What Is Core-Spun Thread?

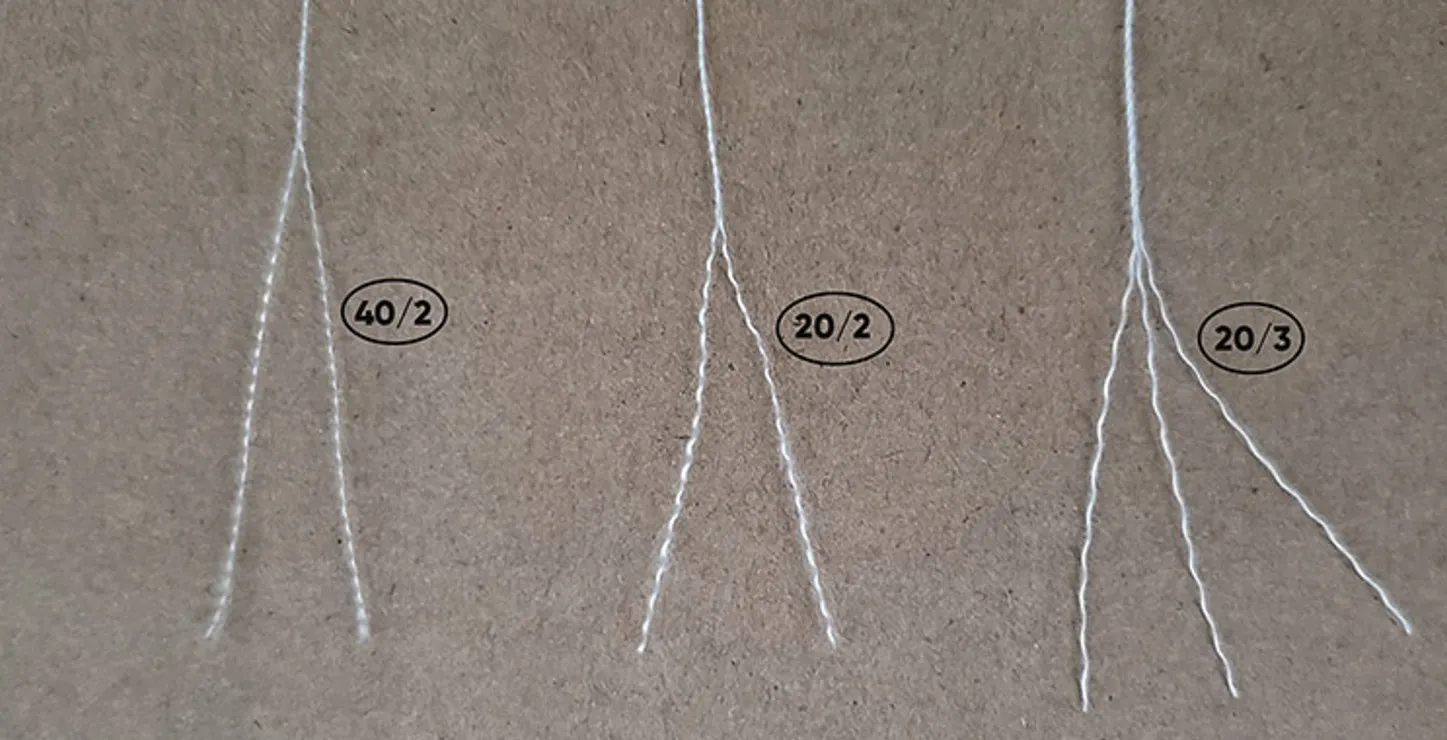

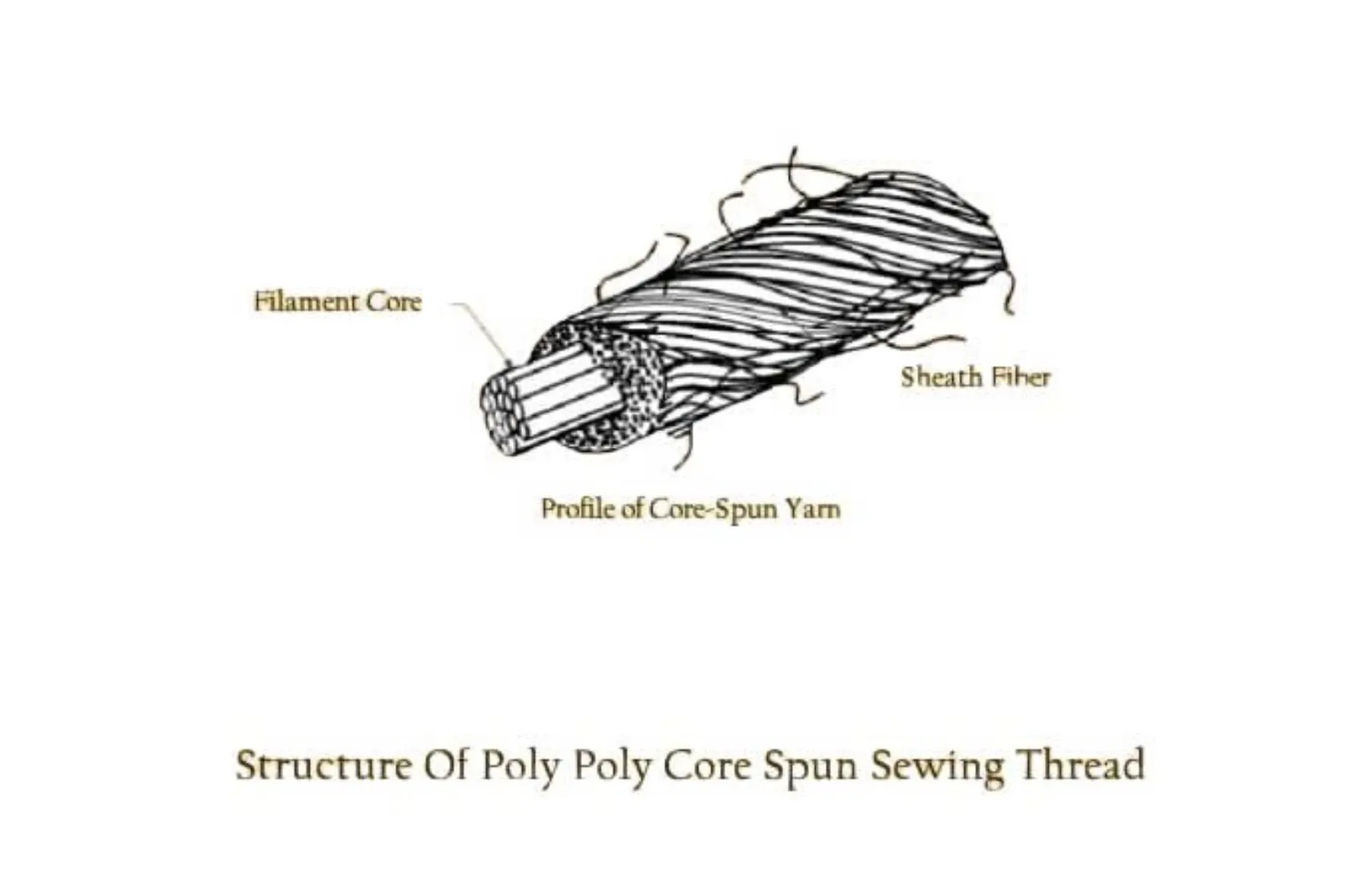

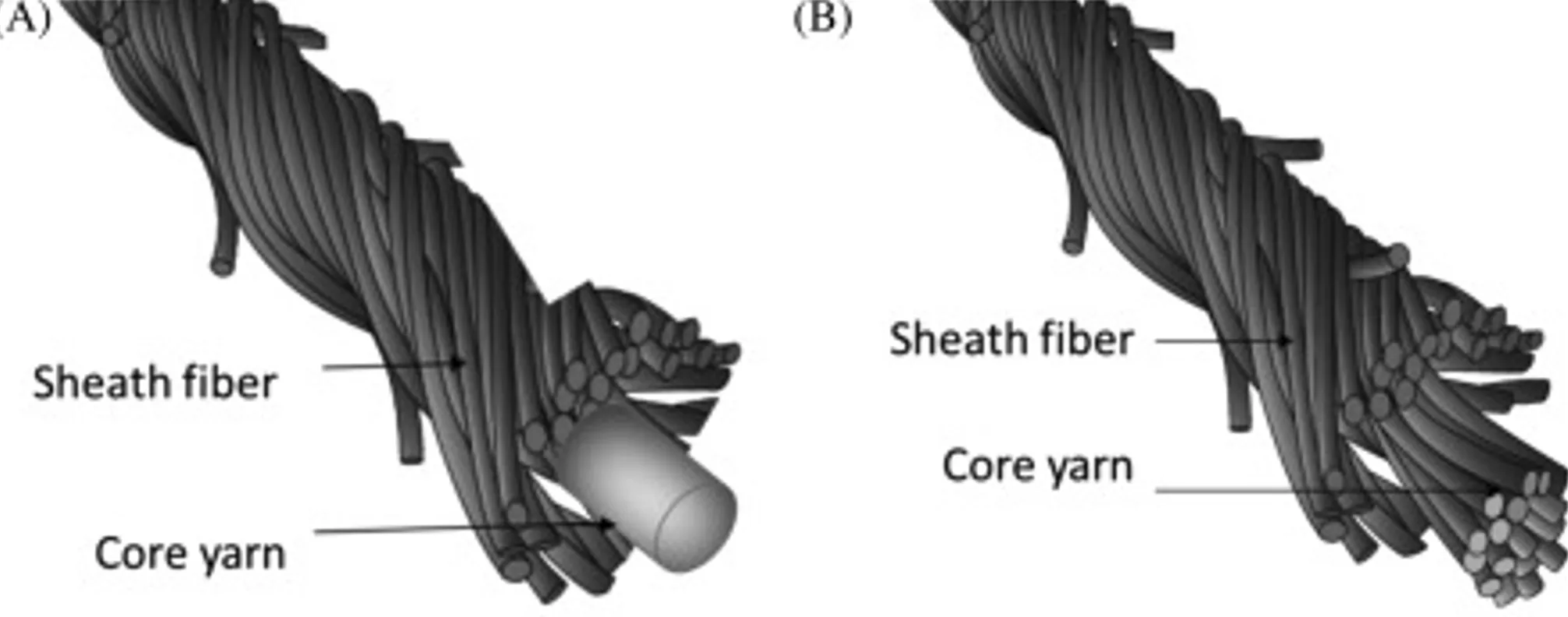

Core-spun thread is a sewing thread built from two parts: a strong filament core and a spun-fiber outer wrap. The core is usually polyester or nylon, made to carry the load and resist breakage. The outer sheath is made from staple fibers like cotton or polyester, giving the thread a softer surface and a more matte look. This design tries to combine strength with good stitch formation. In real production, it’s popular because it performs well across many garment types.

Core-spun thread is a hybrid sewing thread built from two different fiber systems:

- A continuous filament core (usually polyester or nylon)

- A spun fiber sheath wrapped around that core (polyester or cotton staple fibers)

The idea is simple:

- let the core handle strength,

- let the outer wrap handle sewing behavior and appearance.

This structure allows core-spun thread to behave like a spun thread on the surface while delivering the strength of a filament thread inside.

Construction Details: Why Structure Matters

1. Filament Core

Filament core-spun yarn is a strong, versatile yarn made by wrapping short staple fibers (like cotton, wool) around a strong, continuous filament core (like polyester, spandex) to combine properties, offering the comfort/look of the outer fibers with the core’s strength, stretch, and durability, ideal for high-performance apparel like denim, activewear, and sewing threads.

The filament core is the “engine” of core-spun thread. Because it is continuous filament, it delivers high tensile strength and stable performance along long stitch lines. This helps reduce sudden seam failure in stress zones like crotch seams or pocket corners. It also gives consistent elongation, which helps control seam balance. But core strength alone is not enough if the outer wrap is weak or uneven. The core is made from high-tenacity continuous filaments, most commonly polyester. Its role is to provide:

- High tensile strength

- Excellent load consistency

- Resistance to sudden seam failure

- Stable elongation under stress

This is why core-spun seams usually do not snap cleanly. Instead, they slowly abrade or fuzz before failure—an important safety feature in workwear. However, strength alone does not guarantee good sewing.

A spun thread used for sewing

2. Staple Fiber Sheath (Wrapper)

Staple fiber sheath core-spun yarn is a composite yarn with a strong filament core (like polyester or spandex) wrapped by staple fibers (like cotton or wool), combining the filament’s high strength and durability with the staple fibers’ soft feel, low lint, and good dyeability, creating high-performance threads ideal for sewing, denim, and activewear.

The staple sheath is what your needle and fabric touch during sewing. It adds grip, improves stitch formation, and reduces the slippery feel that pure filament threads can have. It also gives the thread a spun-like look, which matters for visible seams. The catch is that the sheath is often the first part to wear down under abrasion. If the wrapping is poor and the core shows through, you can get shine, heat issues, or seam damage. The outer sheath is spun from short fibers, either cotton or polyester. Its purpose is to:

- Improve needle penetration

- Reduce friction at high speed

- Create a matte, fabric-like look

- Improve stitch formation and loop control

But here’s the uncomfortable truth: The sheath is also the weakest part of the thread.

If the wrapping coverage is poor, the filament core can become exposed, causing:

- Needle overheating

- Thread shine

- Fabric cutting

- Premature seam abrasion

So not all core-spun threads are created equal.

Common Types of Core-Spun Thread

Polyester / Cotton (Poly-Cotton Core-Spun)

Poly/cotton core-spun uses a polyester filament core wrapped with cotton fibers. It is chosen when you want strength but still want a more natural, matte surface. It can look better on casualwear and visible stitching compared to fully synthetic wraps. However, cotton sheaths can abrade faster and may not love extreme sewing speeds. It’s a solid “balanced” choice, but not the toughest option in harsh conditions.

- Polyester filament core

- Cotton staple sheath

Strengths

- Soft hand feel

- Matte, natural appearance

- Good for visible seams

Limitations

- Lower heat resistance

- Cotton sheath wears faster

- Not ideal for extreme sewing speeds

Polyester / Polyester (Poly-Poly Core-Spun)

Poly/poly core-spun uses a polyester core and a polyester staple sheath. Factories often prefer it for high-speed lines because it handles heat better and tends to run cleaner. It’s also more resistant to moisture and many common wash conditions than cotton-wrapped threads. The downside is appearance: it can look more synthetic and may show shine on some fabrics. So it’s great for efficiency, but not always best for premium aesthetics.

- Polyester filament core

- Polyester staple sheath

Strengths

- High heat resistance

- Excellent for high-speed machines

- More durable sheath than cotton

Limitations

- Can appear synthetic or shiny

- Less “natural” aging over time

- Harder to distress or wash down

This type dominates industrial mass production, not fashion-driven heritage products.

Key Advantages (And the Hidden Conditions)

Strength and Durability

Yes, core-spun thread is strong—but that strength comes mainly from the filament core. If the sheath wears off early, the seam may still hold, but it will look damaged long before it actually fails. So strength ≠ long-term aesthetics.

Sewability at High Speed

The spun sheath improves:

- Lubricity

- Loop formation

- Needle cooling

But this only works when:

- Twist balance is correct

- Sheath coverage is uniform

- Tension is properly set

Poor-quality core-spun can sew worse than premium spun polyester.

Versatility

Core-spun thread works across many categories—but it is rarely the best option for extreme cases. It is a compromise thread, not a miracle thread.

Limitations You Should Not Ignore

Core-spun thread can fail in subtle ways that confuse QC teams. The most common issue is sheath abrasion, where seams look fuzzy or worn even though they are still strong. Another risk is poor wrap coverage, which exposes the filament core and increases heat and shine. Color mismatch can also show over time if sheath and core dye differently. These problems don’t always appear in-line—they often show after washing, wear, or rubbing tests.

- Sheath abrasion happens before seam failure

- Core exposure can damage fabric

- Color mismatch between sheath and core may appear over time

- Recycling difficulty due to mixed fiber construction

- Not ideal for vintage or washed aesthetics

Ignoring these leads to costly QA issues.

Common Applications (And Where People Get It Wrong)

In upholstery and heavy-duty products, seam failure can be a safety and warranty problem. Core-spun thread helps because the filament core maintains strength under load. It is often used in stress points where seam slippage or seam popping would be costly. Still, surface abrasion is a real issue in upholstery because of constant rubbing. Choosing the right sheath type and ticket size matters as much as choosing core-spun itself.

Denim and Heavy Garments

Core-spun thread is widely used in:

- Jeans assembly

- Workwear seams

- Stress points like crotch and inseam

However, many premium denim brands avoid core-spun for topstitching because:

- It does not fade naturally

- It lacks seam roping character

- It looks too clean after washing

So “perfect for denim” depends on the brand philosophy, not just strength.

Upholstery and High-Stress Seams

In areas where seam failure is unacceptable, core-spun performs well due to:

- Gradual wear behavior

- High load tolerance

- Stable stitch structure

But surface abrasion may appear early if cotton-wrapped.

High-Speed Industrial Manufacturing

Poly-Poly core-spun excels here:

- Better heat resistance

- Fewer thread breaks

- Higher machine efficiency

This is why factories love it even when designers don’t.

Final Verdict: What Core-Spun Thread Really Is

Core-spun thread is not “the best of both worlds.” It is a controlled compromise between strength, speed, and appearance.

Choose it when:

- Production speed matters

- Seam strength is critical

- Consistency is more important than character

Avoid it when:

- Authentic aging is required

- Sustainability is a priority

- Visual seam texture defines the product

Core-spun thread is an engineering solution, not an aesthetic one.