In the garment manufacturing industry, understanding the specifications for sewing threads is extremely important. These specifications help you choose the right type of thread for each product. In this guide, you will learn how to read and analyze values like “60/3”, “40/2”, “20/6”, “40/3”, etc…, and understand the fineness, strength and performance characteristics of each type of thread. This knowledge will improve your product quality and optimise your production process. Let’s explore the details.

Construction of Sewing Thread in the Garment Industry

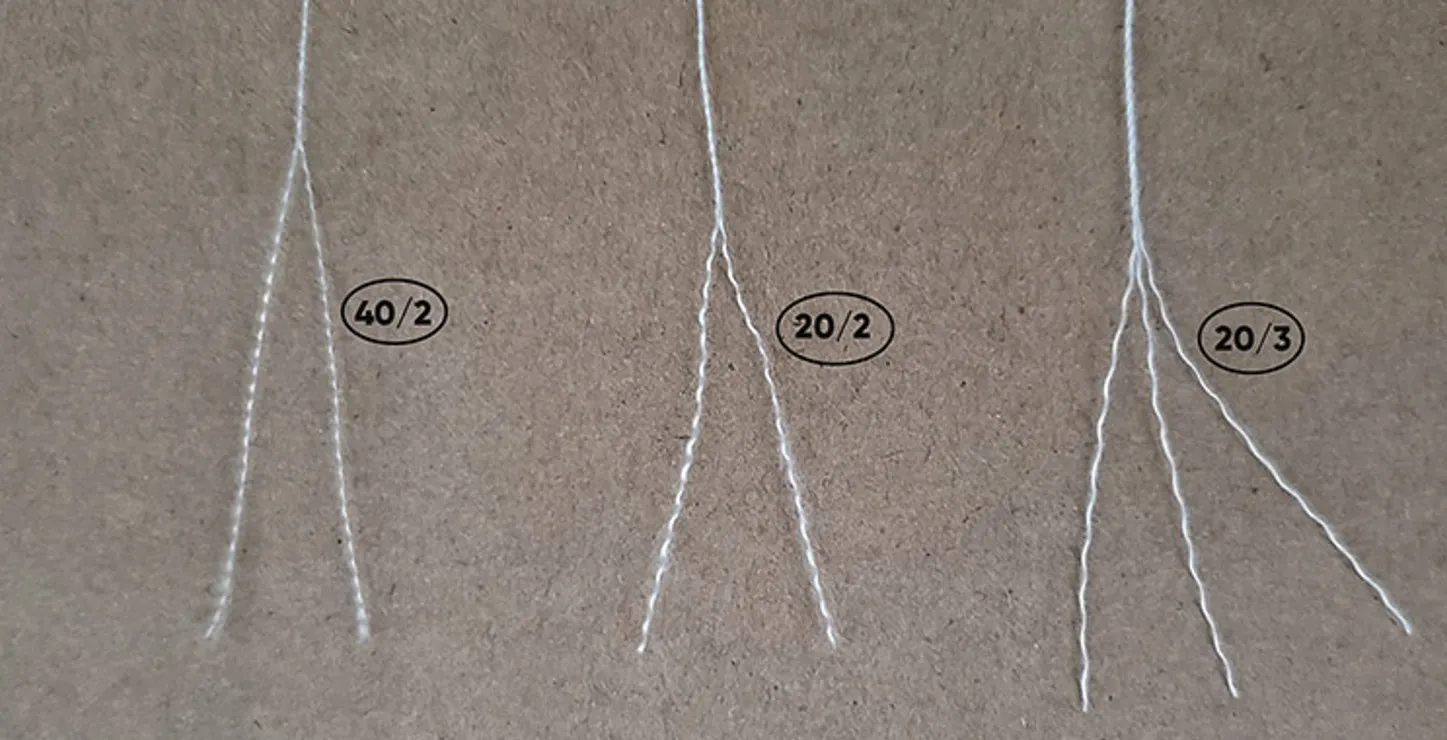

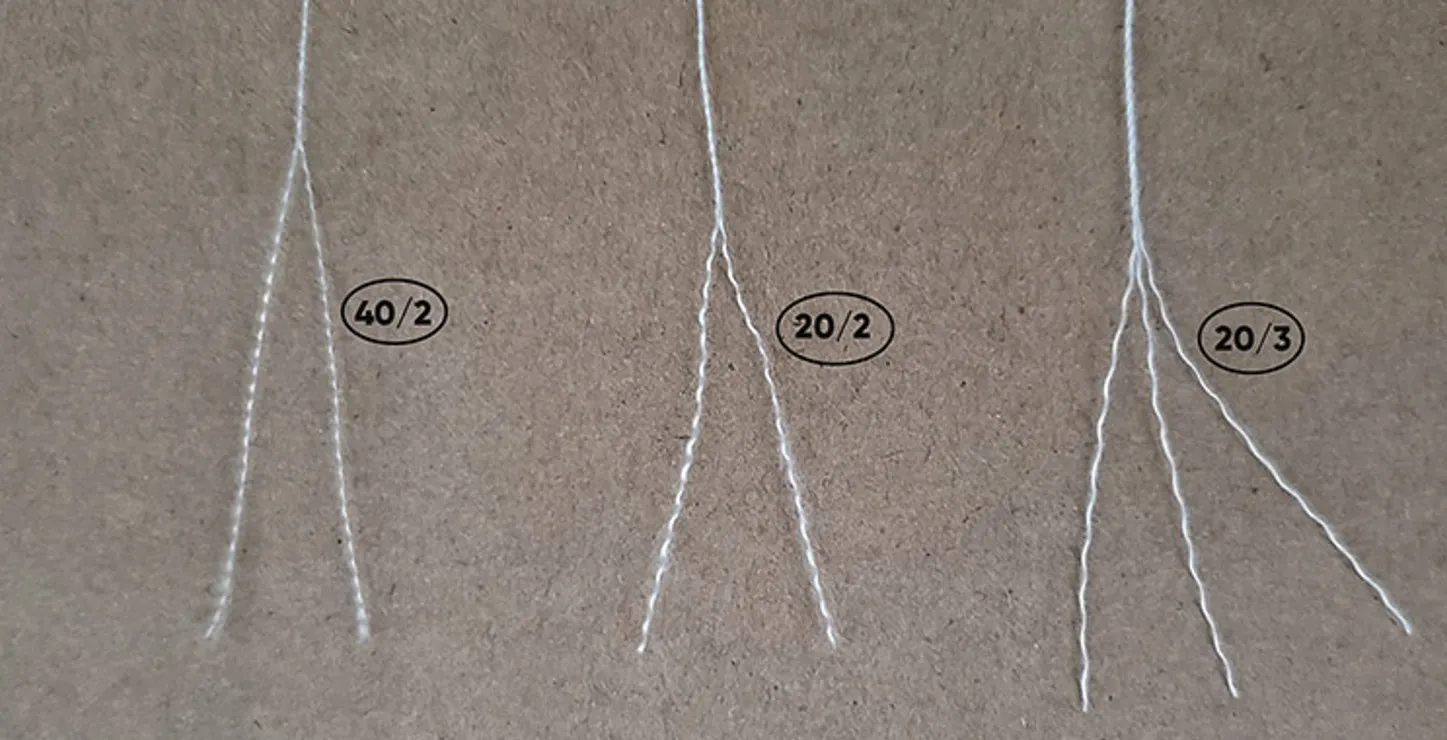

Sewing thread is made up of multiple single filaments twisted together. The number of filaments involved directly determines the strength and robustness of the thread. The thread’s construction doesn’t only affect strength—it also influences how well the thread works with different types of fabric. For example, a “40/2” thread means that two filaments (of a fineness rating of 40) are twisted together; this is a common type of thread in standard garment manufacturing. When choosing sewing thread, understanding its construction helps you make more precise decisions.

Threads that use a larger number of twisted filaments (i.e., a higher second number / “Y” in X/Y) tend to have better tensile strength and are suitable for products that require high durability. This is an important factor because it influences the final product quality—strong, well-made seams contribute significantly to both durability and appearance.

Below is a summary table of common thread specifications:

| Tex | Ne (Construction) | Tensile Strength (cN) |

Elongation (%) |

Length (m) | Singer Needle Size |

|---|---|---|---|---|---|

| 18 | 60/2 | 555 | 19 | 5000 | 9-10 |

| 21 | 50/2 | 730 | 19 | 5000 | 9-10 |

| 27 | 40/2 | 850 | 20 | 5000 | 11-12 |

| 27 | 60/3 | 889 | 20 | 5000 | 11-12 |

| 30 | 50/3 | 1150 | 20 | 5000 | 12-13 |

| 40 | 40/3 | 1355 | 20 | 3000 | 13-14 |

| 40 | 30/2 | 1277 | 20 | 3000 | 13-14 |

| 60 | 20/2 | 1889 | 21 | 3000 | 14-16 |

| 70 | 30/3 | 2085 | 21 | 3000 | 14-16 |

| 80 | 20/3 | 2875 | 21 | 2000 | 16-18 |

| 105 | 20/4 | 3850 | 22 | 2000 | 16-18 |

| 150 | 20/5 | 4799 | 22 | 2000 | 20-21 |

| 180 | 20/6 | 5975 | 22 | 2000 | 22-23 |

| 300 | 20/9 | 8588 | 22 | 600 | 23-24 |

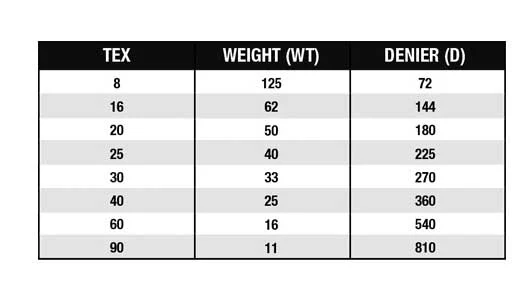

Tex – Thread Thickness

“Tex” is a unit used to measure the weight of a thread, indicating how many grams 1,000 metres of the thread weigh. When you see values like “18”, “21”, “30”, “40”, etc…, they represent the Tex value and hence the thickness of the thread.

- A lower Tex (e.g., 18, 21, 27, 30) means a finer, thinner thread, commonly used for garments requiring high precision, such as lightweight apparel, sportswear, or fine details.

- A higher Tex (e.g., 70, 80, 150, 300) means a thicker, heavier thread, used for products requiring higher strength like jackets, bags, or heavy-duty materials.

=> Read More: How the “Tex” System Measures Thread Thickness ?

Reference table for thread fineness by Tex:

- 10 – 24 Tex → Fine thread. Used for lingerie, lightweight fabrics, or embroidery.

- 30 – 40 Tex → Medium thread. Suitable for shirts, trousers, uniforms.

- 40 – 60 Tex → Slightly heavy thread. Used for jackets, jeans, heavier fabrics.

- Over 60 Tex → Very heavy thread. For backpacks, leather goods, industrial textiles.

For example, a 27 Tex thread means 1,000 metres of that thread weigh 27 grams.

Thread Construction (Ne – e.g., 40/2, 60/3)

A specification like “40/2” or “60/3” tells you about the thread’s structure:

- The first number (e.g., 40 in 40/2) represents the fineness of each single filament (a higher number means a finer filament).

- The second number (e.g., 2 in 40/2, or 3 in 60/3) shows how many single filaments are twisted together to form the finished thread.

Thus:

- Thread 20/X → Thick, large filaments — suitable for heavy-duty applications like shoes, bags, heavy fabrics.

- Thread 40/X → Medium filaments — used for general-purpose fabrics.

- Thread 60/X → Fine filaments — used for lightweight fabrics and precision stitching.

Examples:

- 20/6: Very thick thread, made by twisting six filaments of 20 fineness — used in shoes, backpacks, upholstery.

- 40/2: Common thread for normal garment manufacturing, moderately fine and reasonably strong — suitable for cotton, jersey fabrics.

- 60/3: Finer (filament fineness = 60) but three filaments twisted — used for thin fabrics or industrial mass production needing good seam strength.

This construction directly affects how durable and thick the thread is. For example, 60/3 will be stronger and have higher strength than 40/2 (even though the individual filament is finer) due to the twist of three filaments.

Tensile Strength – Unit: cN (centiNewtons)

The tensile strength of a sewing thread indicates the force it can withstand before breaking, measured in centiNewtons (cN). The higher the tensile strength figure, the more durable the thread is.

- High tensile strength: suitable for products that must bear heavy loads, like bags, jackets, protective gear.

- Lower tensile strength: acceptable for garments that don’t need high-load seams, like lightweight clothing or simple home textiles.

For example, a thread with tensile strength of 555 cN (for Tex 18) is relatively low. In contrast, a thread with tensile strength 2,085 cN (for Tex 60) can withstand much greater force.

Elongation at Break (%)

Elongation at break measures how much the thread can stretch (as a percentage of its original length) before it breaks. This is particularly important when sewing products that need flexibility or stretch, such as sportswear, underwear, or items that move a lot.

- If the elongation is 20%, it means the thread can stretch up to 20% of its original length before it breaks.

- Higher elongation values (20–22%) are better for garments requiring elasticity and movement.

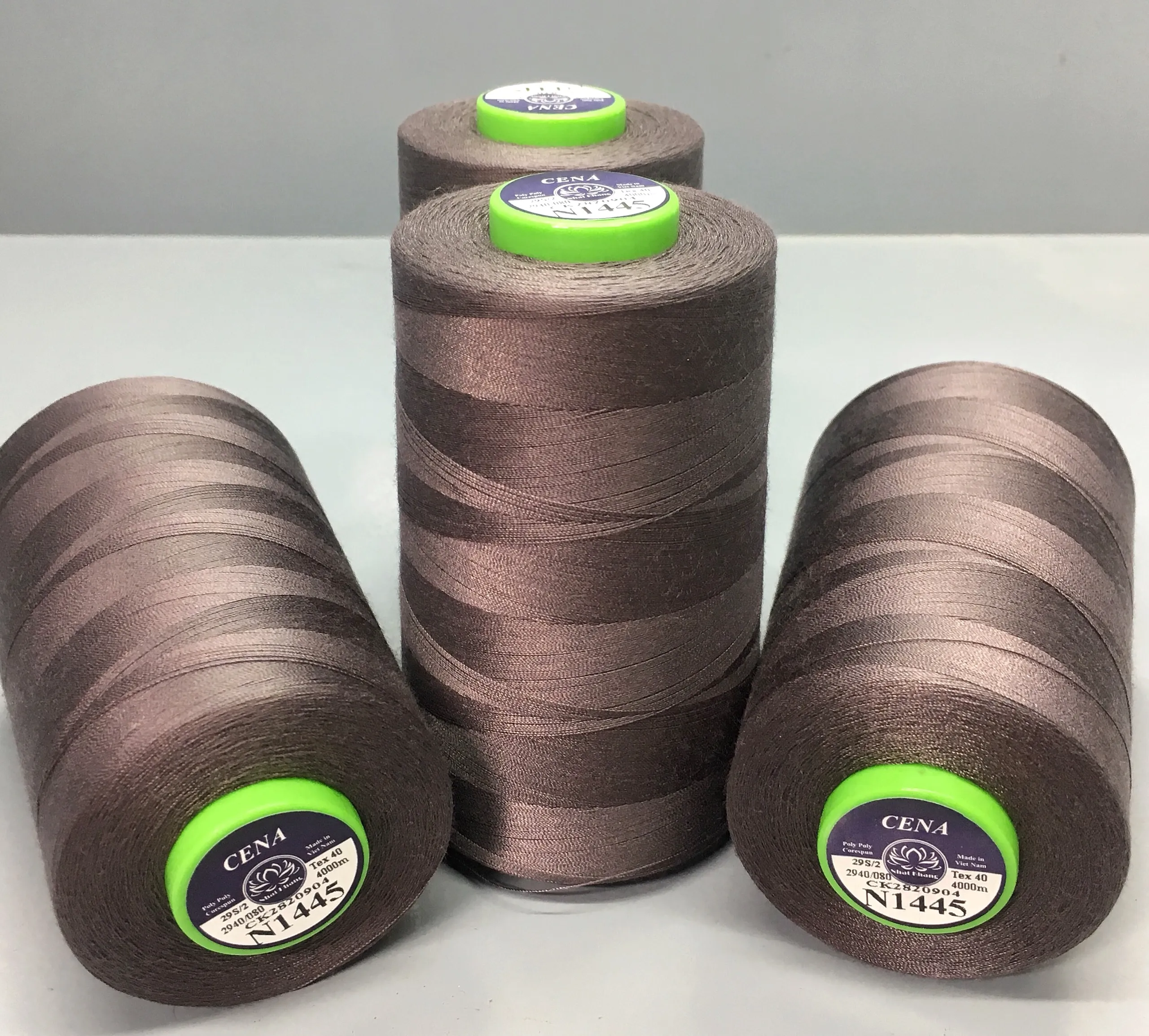

Length (m)

The length specification tells you how many metres of thread are contained in one roll or spool. This helps calculate how much thread you need for production.

- Some threads come in 5,000 m spools, others in 3,000 m or even 2,000 m depending on thickness and application.

- Choosing larger spools can reduce spool changes during production, saving time and reducing cost.

Singer Needle Size

Each type of thread corresponds to a particular size of machine needle, often referenced as the “Singer” needle size. Matching the correct needle size ensures smooth sewing, prevents breaks or skipped stitches, and gives a strong, clean seam. For example, depending on thread thickness and application, needle sizes might range from 9-10 up to 16-18.

How to Read Thread Specifications

At first glance, a label like “Tex 40 – 40/3 – 1355 cN – 20% – 3,000 m – Needle 12–13” may seem confusing. But once you understand what each number means, it becomes a simple language describing the thread’s entire performance. Let’s walk through an example for clarity. Imagine you are choosing thread to sew a sports jacket. You want a thread that is strong, flexible, and durable.

Suppose the specification is:

- Tex: 40

- Construction: 40/3

- Tensile Strength: 1,355 cN

- Elongation: 20%

- Length: 3,000 m

- Needle Size: 12-13

Here’s how you interpret it:

- Tex 40: This is a medium-thickness thread—appropriate for a jacket that needs durability but not overly thick seams.

- Construction 40/3: Three filaments of fineness 40 are twisted together, giving greater strength and better performance than a 40/2 type.

- Tensile Strength 1,355 cN: A reasonably high strength for apparel sewing—good for a jacket that might endure movement or mild stress.

- Elongation 20%: It can stretch up to 20% of its length before breaking—suitable for an active-wear jacket where there’s movement.

- Length 3,000 m: A spool size that gives enough thread without too frequent changes in production.

- Needle size 12-13: The chosen needle size matches the thread thickness and application—ensuring smooth sewing without damage.

Specific Examples of Common Threads

- Thread 40/2: In garment manufacturing, 40/2 is among the most commonly used threads. With fineness 40 and two filaments twisted, it provides moderate strength and is suitable for everyday apparel. Typical uses include cotton fabrics, knitwear, and other standard fabrics. If you need a reliable, all-round thread that balances strength and flexibility, 40/2 is an excellent choice.

- Thread 60/3: Next, 60/3 is ideal for products that need precision and quality in every stitch. With fineness 60 (so a finer filament) and three filaments twisted together, it is appropriate for light fabrics like chiffon or voile, and for industrial production where many seams must look perfect and still be strong. Because of its construction, extra care is needed in production (correct needle size, adjust thread tension) to avoid breakage or pull.

- Thread 20/6: For products requiring high durability and heavy load strength, 20/6 thread is indispensable. With fineness 20 (relatively thick) and six filaments twisted together, it offers optimal strength—ideal for footwear, backpacks, upholstery and other heavy-duty goods. If you are working with heavy materials or need seams that last, 20/6 is the go-to choice.

Notes When Selecting Sewing Thread

- The smaller the first number (fineness) in X/Y, the thicker the filament—and therefore the thread is bulkier and stronger, suited for heavy fabrics or heavy-duty items.

- The larger the first number, the finer the filament—and the thread is thinner and more suitable for lightweight fabrics and fine sewing.

- The larger the second number (the number of filaments twisted together), the stronger the thread will be for the same fineness number.

Conclusion / Final Thoughts

Understanding how to read and interpret sewing thread specifications doesn’t just help you choose the right thread for each product. It also enables you to optimise your production process, ensure seam durability and improve the aesthetics of your finished garments. Once you’re comfortable reading values like Tex, tensile strength, elongation, and needle size, you’ll be equipped to make accurate and effective thread selections—helping you produce high-quality garments.

FAQs Sewing Thread Specifications

In Short, What do the numerical values in thread construction, such as “40/2” or “60/3”, actually represent?

These numbers refer to the thread’s physical structure and composition. The first number (e.g., 40 or 60) indicates the fineness of the single filament; a higher number generally implies a finer, thinner filament. The second number (after the slash, e.g., 2 or 3) represents the number of these single filaments twisted together to form the final thread. Therefore, a “40/2” thread consists of two filaments with a fineness rating of 40 twisted together. A “60/3” thread comprises three filaments of fineness 60. This construction directly influences the thread’s thickness and durability, with a higher number of twisted filaments typically resulting in greater tensile strength.

In short, How is the “Tex” system used to measure thread thickness?

The “Tex” system is a standard unit of measure used to determine the weight and thickness of a thread. Specifically, it indicates how many grams 1,000 metres of that thread weigh. For instance, if a thread is labeled as “27 Tex,” it means that 1,000 metres of that specific thread weighs exactly 27 grams. Because this is a direct numbering system, the relationship is straightforward: the higher the Tex value, the heavier and thicker the thread is. Manufacturers use this value to categorize threads, ranging from fine threads (Tex 18 or 21) to much thicker options (Tex 60 or 80). => Read More: How the “Tex” System Measures Thread Thickness ?

Why is Tensile Strength (cN) a vital metric for product quality?

Tensile strength measures the maximum force a thread can withstand before it snaps, expressed in centiNewtons (cN). This metric is imperative for ensuring the longevity and durability of the final garment. A higher cN figure indicates a stronger thread capable of enduring significant stress. For example, a fine thread (Tex 18) might have a tensile strength of around 555 cN, whereas a heavy-duty thread (Tex 60) can withstand up to 2,085 cN. selecting a thread with adequate tensile strength prevents seam failure during the garment’s use.

How does “Elongation at Break” affect the suitability of thread for different garments?

Elongation at break is measured as a percentage and indicates how much a thread can stretch relative to its original length before breaking. This characteristic is particularly significant when manufacturing flexible items such as sportswear, underwear, or activewear. If a garment is designed to stretch with the wearer’s movement, the sewing thread must possess high elongation properties to expand along with the fabric. If the thread lacks sufficient elongation, the seams are likely to snap when the fabric is stretched, compromising the garment’s integrity.

How do I determine the correct Singer Needle Size for a specific thread specification?

The Singer needle size must be compatible with the thickness of the thread to ensure smooth production and high-quality seams. Using the wrong needle size can lead to thread breakage or skipped stitches. Generally, finer threads (like Tex 18-24) require smaller needles, such as sizes 9-11, to maintain precision. Conversely, thicker, heavy-duty threads (like Tex 60-80) require larger needles, typically sizes 16-18, to accommodate the thread’s diameter without friction. Matching the needle size to the thread specification ensures the production process remains efficient and the seam finish is clean.

Can you provide examples of thread specifications used for heavy-duty versus light-duty applications?

For heavy-duty applications like jeans, workwear, or jackets, manufacturers typically use threads with specifications such as Tex 60 or Tex 80. These might appear as “20/2” or “20/3” in construction, offering high tensile strength (e.g., 2,085 cN or higher) to withstand rough usage. In contrast, for light-duty applications like shirts, blouses, or lightweight fashion items, finer threads are selected. These generally fall in the Tex 18 to Tex 24 range, with constructions like “60/2” or “50/2,” and lower tensile strengths (around 555 cN to 800 cN) to ensure the seams are unobtrusive and delicate.

Aside from technical specifications, what other factors should be considered when selecting thread?

While specs like Tex and tensile strength are foundational, you must also consider the compatibility of the thread with the fabric material. The weight of the thread should align with the weight of the fabric; heavy fabrics require stronger threads, while delicate fabrics need finer threads to avoid puckering. Additionally, properties such as color fastness are imperative to ensure the thread does not fade or bleed during washing. Shrinkage is another factor; the thread should have a shrinkage rate similar to the fabric to prevent the seams from distorting after the garment is laundered.