How to Get T-Shirts Manufactured in Vietnam

Vietnam has become one of the world’s most trusted apparel manufacturing hubs. From global fashion brands to fast-growing D2C labels, more and more companies are choosing Vietnam to manufacture t-shirts not because it’s the cheapest option, but because it offers a rare balance of quality, flexibility, and production discipline. If you’re a brand owner asking, “How do I actually get t-shirts manufactured in Vietnam — without losing control or burning cash?” this guide is for you. This is not a surface-level overview. It’s a factory-grounded breakdown of the real process, the decisions that matter, and the mistakes that quietly destroy margins and brand trust.

Why Vietnam Is a Strategic Choice for T-Shirt Manufacturing

Before talking about how, let’s challenge a common assumption. Many brands come to Vietnam expecting China-level scale with Bangladesh-level pricing. That expectation is wrong and dangerous. Vietnam excels because it offers:

- Strong cut-and-sew quality

- Skilled labor for knitwear and jersey

- Reliable compliance and export processes

- Better communication and transparency than many low-cost regions

Vietnam is not the cheapest place to make t-shirts. It is one of the best places to make consistent, export-ready, brand-grade t-shirts. If your brand depends on repeat buyers, sizing accuracy, and fabric feel, Vietnam makes sense.

Step By Step to Get T-Shirts Manufactured in Vietnam

Getting t-shirts manufactured in Vietnam isn’t just “find a factory and place an order.” It’s a controlled process from defining specs and fabric sourcing to sewing, printing, quality checks, and export. The brands that win treat this like a system, not a one-time task. Below is the step-by-step workflow Vietnamese manufacturers follow, plus the key decisions you must lock in at each stage to keep quality consistent and avoid costly mistakes.

Step 1: Define Your Product Clearly (Before Contacting Any Factory)

Most brand owners contact factories too early. They ask for pricing before they can describe the product clearly — and then wonder why samples come back “almost right” but never perfect. Before you message any factory in Vietnam, lock your t-shirt down like a real product, not an idea: fabric type, GSM range, fit, size chart, color standards, and branding method. If you can’t define these in writing, the factory will fill the gaps for you and the result will be inconsistent across bulk production.

Most brand owners rush this step and pay for it later. Before you speak to a Vietnamese manufacturer, you must lock down:

- Fabric type (100% cotton, cotton-poly, organic, recycled)

- Fabric structure (single jersey, interlock, rib)

- GSM range (and tolerance, usually ±5%)

- Fit type (standard, slim, oversized)

- Target market (domestic, US, EU, Japan)

Hard truth: Factories can’t “figure this out for you.”If your product definition is vague, your outcome will be inconsistent. A serious manufacturer in Vietnam will expect tech packs or at least clear references. If a factory says “don’t worry, we’ll handle everything”, be cautious.

Step 2: Fabric Sourcing and Knitting in Vietnam

Step 2 is where your t-shirt’s real quality is decided — before a single stitch happens. In Vietnam, the smartest brands don’t start by arguing about sewing price. They start by locking down fabric: yarn type, knitting structure, GSM range, and finishing. If you get this wrong, no amount of “good stitching” will save the final product from shrinkage, twisting seams, rough hand-feel, or inconsistent color. Vietnam’s t-shirt supply chain is strongest in knit fabrics, especially cotton and cotton blends.

What Actually Happens:

- Yarn sourcing (local or imported)

- Knitting (usually circular knitting machines)

- Pre-treatment: Bio-wash (for softness), Compacting (to reduce shrinkage), Heat setting (for blends)

Most quality issues start here, not in sewing. If you don’t specify shrinkage limits, color fastness, and hand feel expectations, you’re leaving quality to chance. Vietnamese factories are capable but they follow instructions, not assumptions.

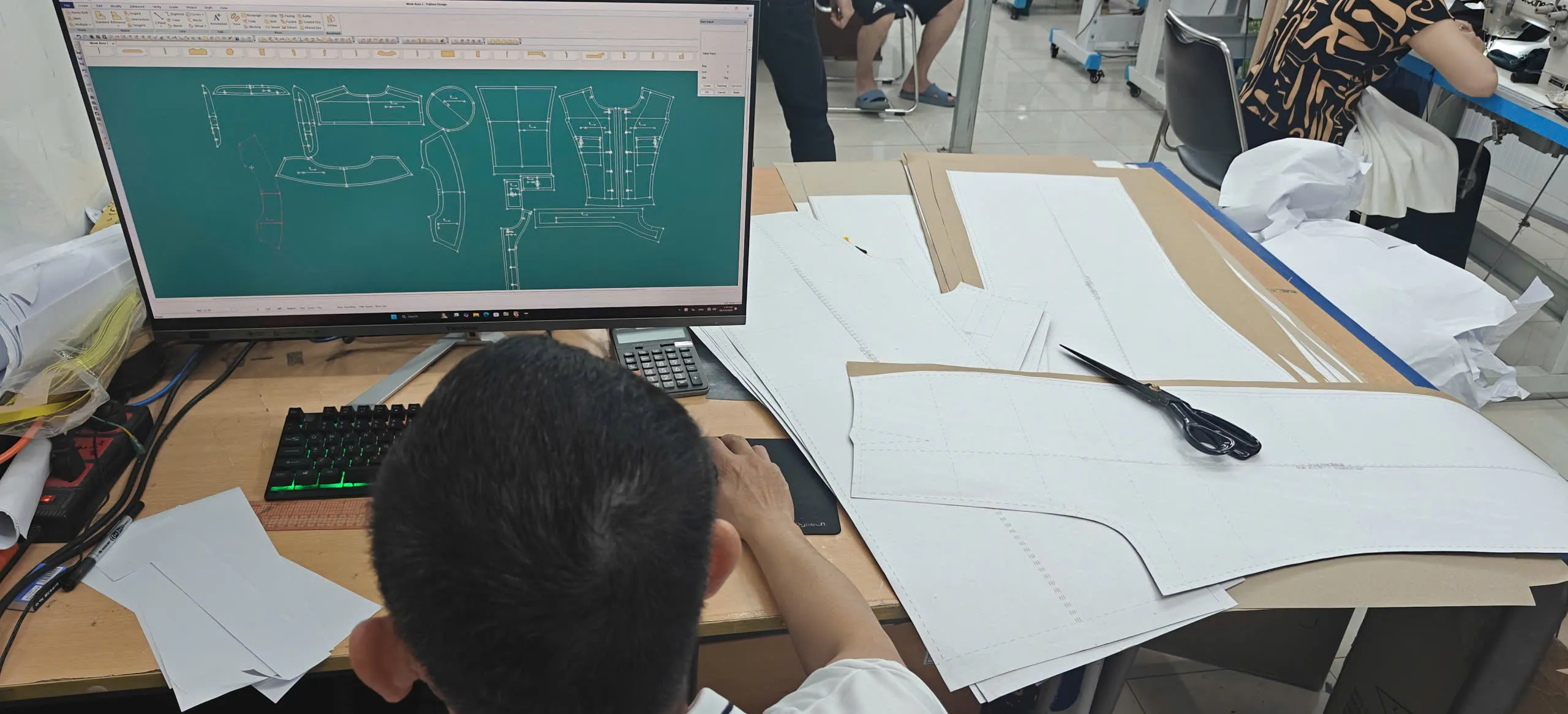

Step 3: Pattern Making and Fabric Cutting

This stage determines fit consistency and cost efficiency. Most t-shirt “quality problems” don’t start in sewing, they start in pattern and cutting. If your pattern isn’t right, every size will feel off. If your cutting isn’t consistent, bulk production will drift even when the sample looked perfect. Step 3 is where you lock in fit, control fabric waste, and protect your margins because cutting mistakes are expensive and almost impossible to hide.

Key Processes:

- CAD pattern development (size grading)

- Marker planning (fabric utilization)

- Layered cutting (manual or automated)

- A common mistake brand owners make is focusing only on samples.

- Bulk cutting exposes weak patterns fast.

Ask your factory:

- What tolerance do you allow per size?

- Do you cut in-house or outsource?

- How do you control shade variation between rolls?

- If they can’t answer clearly, that’s a red flag.

Step 4: Stitching – Where Brand Quality Is Won or Lost

Step 4 is where your t-shirt becomes a real product. Stitching and assembly determine how the garment feels on the body, how it survives washing, and whether it still looks good after months of wear. Many brands obsess over fabric and printing, then under-spec stitching — and that’s how necklines stretch, seams twist, and returns quietly pile up. In Vietnam, skilled stitching is available, but only if your construction standards are clear.

Standard T-Shirt Stitching Includes:

- Overlock for joining panels

- Flatlock for comfort areas

- Double-needle stitching for hems

- Neck rib attachment with reinforcement

- Shoulder taping for durability

Important: “Good stitching” is not subjective. It’s measurable:

- SPI (stitches per inch)

- Seam strength

- Consistency across sizes

Brand owners who don’t define stitching specs usually end up with:

- Wavy hems

- Loose necklines

- Inconsistent sleeve angles

Step 5: Printing and Branding Options in Vietnam

Step 5 is where a blank t-shirt becomes your product. Printing and branding add identity, but they also introduce the highest risk of inconsistency, delays, and rework if not planned correctly. Many brand owners choose print methods based on appearance alone, then struggle with wash durability, color variation, or scaling costs. In Vietnam, nearly every major print technique is available — the challenge is choosing the right one for your fabric, volume, and long-term brand strategy.

Vietnam supports nearly all mainstream t-shirt customization methods:

- Screen printing – best for scale

- DTG – small batches, high detail

- DTF – flexible and rising fast

- Sublimation – polyester only

- Puff print – popular in streetwear

- Embroidery – premium branding

Unpopular truth:

- DTG is often a poor long-term choice for scaling brands due to ink cost, wash durability, and speed limitations.

- A good Vietnamese manufacturer will tell you this not sell you whatever you ask for.

Step 6: Quality Control (Do Not Skip This)

Step 6 is the last line of defense between your factory and your customer. Once t-shirts leave the production floor, every defect becomes your problem not the manufacturer’s. Quality control, packing, and dispatch are where sizing errors, print flaws, and labeling mistakes are caught or missed. In Vietnam, strong QC systems exist, but only brand owners who insist on them benefit. Quality control is not optional, especially for export or private label brands.

QC Typically Includes:

- Visual inspection

- Measurement checks

- Print placement verification

- Label and packaging accuracy

- Random AQL sampling (for bulk)

Critical mindset shift:

- Your customer doesn’t see your factory.

- They see your logo.

- Skipping QC saves money today and costs reputation tomorrow.

Step 7: Packing, Logistics, and Export

Step 7 is where manufacturing becomes fulfillment. Packing, logistics, and export determine whether your t-shirts arrive sell-ready or create costly delays, damage, and compliance issues. Many brand owners underestimate this stage, assuming shipping is “just logistics.” In reality, incorrect packing methods, weak carton labeling, or export paperwork errors can undo months of careful production in a single shipment.

Vietnam is strong in export logistics. if your paperwork is correct. Final Stage Covers:

- Folding and tagging

- Polybag or bulk packing

- Carton labeling

- HS codes and documentation

- Freight coordination (FOB, CIF, DDP)

If you sell internationally, choose a manufacturer who understands export compliance, not just sewing.

What to Look for in a Vietnamese T-Shirt Manufacturer

Don’t choose based on price alone. That’s how brands get stuck. Evaluate Based On:

- Fabric control (in-house or trusted mills)

- Clear MOQ structure (not vague promises)

- Sampling discipline

- In-house printing & labeling

- Transparent timelines

- Communication quality

A good manufacturer will say no when your request risks quality. A bad one will say yes to everything and disappoint you later.

Final Thoughts: Manufacturing Is a Strategy, Not a Task

Learning how to get t-shirts manufactured in Vietnam is not about finding a factory. it’s about building a reliable production system that protects your brand as you grow. Vietnam rewards brands that:

- Plan clearly

- Respect process

- Choose partners, not just vendors

If that sounds like your approach, you’re already ahead of most.

Why Brand Owners Work with Mekong Garment

At Mekong Garment, we work with brand owners who want control, consistency, and long-term scalability, not shortcuts. We support:

- Private label t-shirts

- Small test runs with growth in mind

- Clear production specs

- Fabric-first decision making

- Export-ready quality standards

We don’t position ourselves as “the cheapest.”We position ourselves as a manufacturing partner who understands brand risk.