Heat Transfer Vinyl (HTV) Printing: Pros, Cons and Benefits

Heat Transfer Vinyl (HTV) printing is one of the most talked-about apparel decoration methods out there. It sounds simple: cut vinyl, press it to a shirt, boom, custom tee. But for brand owners, the real question isn’t “what it is”, it’s “should I use it for my brand?” Today we cut through the marketing hype and give you a grounded, experience-based look at HTV printing: how it works, where it shines, where it struggles, and how it compares to other methods.

=> Read More: T Shirts Manufacturing Vietnam | Mekong Garment Factory

T-Shirt Printing Methods Comparison:

- Screen Printing for T-Shirts: What It Is, Pros, Cons, Costs, and When to Use It

- Direct-to-Garment (DTG) Printing for T-Shirts: Pros, Cons, and What Brands Must Know

- Direct-to-Film (DTF) Printing for T-Shirts: Pros, Cons

- What Is Heat Transfer Printing for T-Shirts: Pros, Cons, Benefits,…

- Sublimation Printing for T-Shirts: Pros, Cons and Guide for Brand Owners

- Puff Printing for T-Shirts: Pros, Cons, Benefits and Guide for Brand Owners

- Heat Transfer Vinyl (HTV) Printing: Pros, Cons and Benefits

- What Is Embroidery for T-Shirts? A Brand Owner’s Guide

What Is Heat Transfer Vinyl (HTV) Printing?

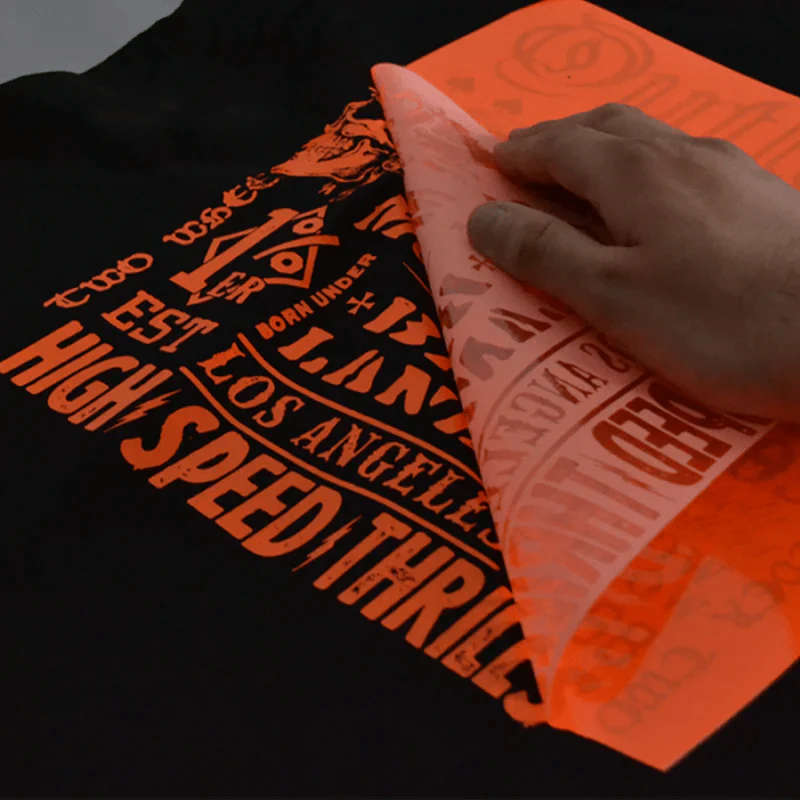

Heat Transfer Vinyl (HTV) printing is a garment decoration method where a pre-colored vinyl film is cut into a design and then bonded onto a T-shirt using heat and pressure. Unlike ink-based printing, HTV sits on top of the fabric as a thin layer, making it a practical option for simple logos, names, and small custom runs. Understanding how HTV works—and how it differs from screen printing, DTF, or DTG—helps brand owners choose the right method for quality, cost, and scalability.

At its core, HTV is not “printing ink”, it’s a plastic film cut into shapes that get bonded to fabric using heat and pressure. The process flow is:

- Create or import a design

- Cut it from colored vinyl sheets

- Weed out excess material

- Heat-press the vinyl onto the garment

- Remove the carrier sheet once it cools

Because every color is a separate cut and layer, HTV works very differently from screen printing, DTF, or direct-to-garment methods. The devil is in the details, and that’s where many brands trip up.

Best Fabrics for HTV

HTV can bond well to many T-shirt fabrics, but results aren’t equal across all materials. Fabric surface, heat tolerance, and stretch all affect adhesion, durability, and how the design feels when worn. Before you commit HTV to a product line, it’s smart to match the vinyl type to the fabric, so you avoid issues like edge lifting, scorching, or cracking after wash. HTV works well on:

- Cotton & cotton blends classic choice

- Polyester & sports fabrics with correct temp control

- Smooth surfaces textured fabrics can reduce adhesion

Avoid HTV on delicate knits or fabrics that can’t tolerate required press temperatures.

Pros and Cons of Heat Transfer Vinyl (HTV) Printing

Heat Transfer Vinyl (HTV) is popular because it’s simple to produce and works well for small runs, personalization, and bold designs. But HTV isn’t a “one-size-fits-all” solution. Before choosing it for your T-shirt line, you need to weigh the real trade-offs especially around fabric feel, design complexity, production speed, and cost at scale. Below are the key pros and cons to help you decide if HTV fits your brand’s product and margins.

Pros: When HTV Makes Sense

- Low Startup Cost: HTV doesn’t need screens, ink systems, or high-end printers. A cutter and a heat press are enough to get moving. That’s great for small runs and prototypes. A low startup cost doesn’t guarantee low total cost. Labor adds up fast once you’re past the first dozen shirts.

- Highly Customizable at Small Scale: Names, numbers, initials, limited editions, HTV lets you personalize easily. For brands doing personalized drops or small batch runs, this is a real advantage. However, if your brand plans to scale personalization to hundreds of SKUs per week, this advantage shrinks because each unit still demands manual weeding and pressing.

- Wide Range of Special Effects: Matte, gloss, glitter, puff, holographic, HTV offers effects that many other methods don’t. These can help a brand stand out visually. Special effects are great until they compromise wearability or comfort. Not every customer wants puff vinyl on a lightweight shirt.

- Durable If Applied Correctly: When heat, pressure, and time are dialed in, HTV can last 30–50 washes without peeling. But that durability is highly dependent on process discipline. Slight temperature drift or uneven pressure and the lifetime drops sharply.

Cons: The Hard Truths

- Limited Detail: HTV struggles with fine lines, gradients, and photographic imagery because each color is a cut layer. This is not the right method if your brand’s identity depends on detailed art or photo-real graphics.

- Adds a Noticeable Layer: Even “soft” vinyl sits on top of the fabric. Customers will feel it. This is not ideal for luxury apparel where hand feel is part of the value proposition. If your design philosophy prioritizes garment feel, HTV is often a compromise, not a solution.

- Labor Intensive: Weeding and layering each color is manual, and each step introduces cost and inconsistency. In contrast, screen printing scales better because labor is concentrated in setup, not in every garment.

- Temperature Sensitivity: Too hot = vinyl warp, shrink, or blister. Too cool = adhesive doesn’t bond fully. This makes HTV less forgiving than some competitors.

HTV vs Other Methods

Heat Transfer Vinyl (HTV) can look great on a T-shirt, but it’s not always the best choice for every design or order size. The “right” printing method depends on what you’re making: simple logos, full-color artwork, special effects, or large production runs. In this section, we’ll compare HTV with other popular methods so you can choose based on cost, durability, feel on fabric, detail level, and scalability not just what looks good in a photo.

| Printing Method | Best Use Case | Design Detail Level | Feel on Fabric | Cost Efficiency by Volume | Production Scalability |

|---|---|---|---|---|---|

| Heat Transfer Vinyl (HTV) | Names, numbers, simple logos, small custom runs | Low to medium (solid shapes, limited colors) | Noticeable vinyl layer on surface | Low cost for small runs, high labor cost at scale | Low to medium |

| Screen Printing | Logos and graphics for bulk orders | Medium (not ideal for photos) | Soft, ink absorbs into fabric | Very cost-effective for large quantities | High |

| DTF (Direct-to-Film) | Full-color artwork, complex designs | High (photos, gradients, fine details) | Medium (thin printed layer) | Good balance for small to large runs | Medium to high |

| DTG (Direct-to-Garment) | Detailed designs on small orders | High (photo-quality on cotton) | Very soft | High cost per piece | Low |

| Sublimation | All-over prints on polyester | Very high (vivid, permanent color) | No feel (ink becomes part of fabric) | Very efficient for large polyester runs | High (polyester only) |

Practical Tips for Brand Owners

HTV results can vary a lot from one factory or operator to another. Small changes in heat, pressure, fabric type, or vinyl quality can turn a “durable print” into peeling edges after a few washes. These practical tips focus on what brand owners care about most: consistent quality, fewer rejects, and repeatable production so your HTV orders come out clean across every batch.

- 1. Always test before scaling. Color, temperature, pressure, and fabric all interact.

- 2. Pre-press garments. This removes moisture and wrinkles to improve bonding.

- 3. Match vinyl type to wear goals. Glitter and special effects look great, but not at the expense of comfort.

- 4. Standardize your press settings. Make a calibration reference and use it every time.

- 5. Consider customer perception. HTV feels different from “ink.” Be honest in your product descriptions.

When HTV Is the Right Choice

HTV makes sense when your brand:

- Wants customization without big screen setup costs

- Is testing designs before larger screen or DTF production

- Values special visual effects

- Has small to moderate production volumes

When You Should Look Elsewhere

HTV might not be the best choice when your brand:

- Needs high detail graphics

- Requires premium soft hand feel

- Is targeting large runs with tight cost control

In many cases, a hybrid approach (HTV for names/logos, screen printing for art, DTF for full-color pieces) gives the best balance of quality, cost, and flexibility.

Final Thought: Don’t Choose HTV by Default

HTV isn’t “bad”, it’s a tool with defined strengths and limits. As a brand owner, your job is to match tools to goals, not assume one method fits every need. If your brand’s identity depends on detail, comfort, and consistency, take a hard look at alternatives like screen printing or DTF for your core line, and use HTV strategically for personalization and effects.