Silk thread is one of the most “premium-feel” choices you can make for a garment especially when the product story is about elegance, comfort, and craftsmanship. It creates a smooth, refined stitch line that looks expensive on camera and feels gentle on skin. That said, silk thread is not a universal upgrade. If you use it in the wrong product category, you can pay more and still lose performance. This guide explains what silk thread is, how it’s made, where it shines, where it fails, and how brand owners can spec and approve it without costly surprises.

What Is Silk Thread?

Silk thread is sewing thread made from silk fibers produced by silkworm cocoons. In sewing and embroidery, it’s valued for:

- Natural luster (a soft glow, not a plastic shine)

- Smooth hand-feel against delicate fabrics

- Clean stitch appearance on luxury materials

Silk thread typically comes in two major types:

1) Filament Silk Thread (Continuous Filament)

Made from long, continuous silk filaments reeled from cocoons.

What you’ll notice:

- Smoother, more even surface

- More natural sheen

- Excellent for decorative stitching and visible topstitch when the brand wants a polished look

2) Spun Silk Thread (Staple/Spun)

Made from shorter silk fibers spun like cotton yarn.

What you’ll notice:

- Softer, slightly more “matte”

- Often easier to sew with on certain fabrics

- Great for seams on silk/linen blends where you want a refined look without overly glossy stitches

Many brands assume silk thread is always “best.” It’s not. It’s best when your product value is visual finesse + tactile comfort, not heavy-duty durability.

Key Properties of Silk Thread (What Matters in Production)

Silk thread isn’t just “prettier thread.” In production, it behaves differently from polyester or nylon—especially on delicate fabrics like silk, chiffon, organza, and premium linen. The key is to understand how silk reacts to tension, needle choice, machine speed, heat, sweat, and washing. When those factors are controlled, silk gives a clean, luxury stitch line. When they aren’t, you can get breakage, puckering, or weak seams despite paying more.

Smooth, Low Friction on Delicate Fabrics

Silk thread can reduce stitch harshness on thin fabrics and help the seam look cleaner—if machine setup is correct. Pushback: If tension, needle, or speed is wrong, silk can still cause puckering or fraying. It’s premium, not magic.

Strength: Good Among Naturals, Lower Than Synthetics

Silk is generally:

- Stronger than many natural threads

- Weaker than polyester and nylon in high-stress use

If your product gets pulled, stretched, or abraded often—silk thread may be the wrong choice.

Elasticity: Low to Medium

Silk thread is not ideal for:

- High-stretch knitwear

- Sportswear seams under repeated stretch

Moisture Absorption: Comfortable but More Sensitive

Silk absorbs moisture better than many synthetics, which supports comfort. But it also means: Sweat, chemicals, and harsh detergents can affect it faster

Sensitivity to UV and Harsh Chemicals

Long exposure to strong sunlight and harsh alkaline chemicals can weaken silk fibers. Brand risk: If your product is often worn outdoors in heat/sun (or requires aggressive washing), silk thread can become a durability liability.

Pros and Cons of Silk Thread

Silk thread can make a garment look and feel more premium, but it’s not a free upgrade. It delivers a refined stitch line and luxury hand-feel, yet it also comes with higher cost and stricter handling requirements. Before you spec silk thread for production, you should weigh the benefits against the real risks especially durability, care conditions, and where the garment will be worn.

Advantages

- Natural luxury sheen and deeper color appearance

- Refined stitch line on silk and premium wovens

- Excellent for: Hand embroidery, Decorative stitching, Buttonholes / couture finishing, High-end linings and edge finishing

Disadvantages

- Higher cost

- Lower performance than polyester/nylon for stress-heavy products

- More sensitive to sweat, sunlight, strong detergents, and alkaline chemicals

- Requires stricter QC and testing before mass production

Hard truth: If your customer wears and washes the item aggressively, silk thread may reduce product lifetime and increase complaints, no matter how premium it looks on Day 1.

How to Specify Silk Thread Correctly (Type, Size, Needle)

If you’re a brand owner, the most common mistake is asking a factory for “silk thread” without specifying type + size + application. Do this instead:

1) Choose the Type

- Filament silk: best for visible premium sheen and clean topstitch lines

- Spun silk: best for softer look/feel and many seam applications on luxury fabrics

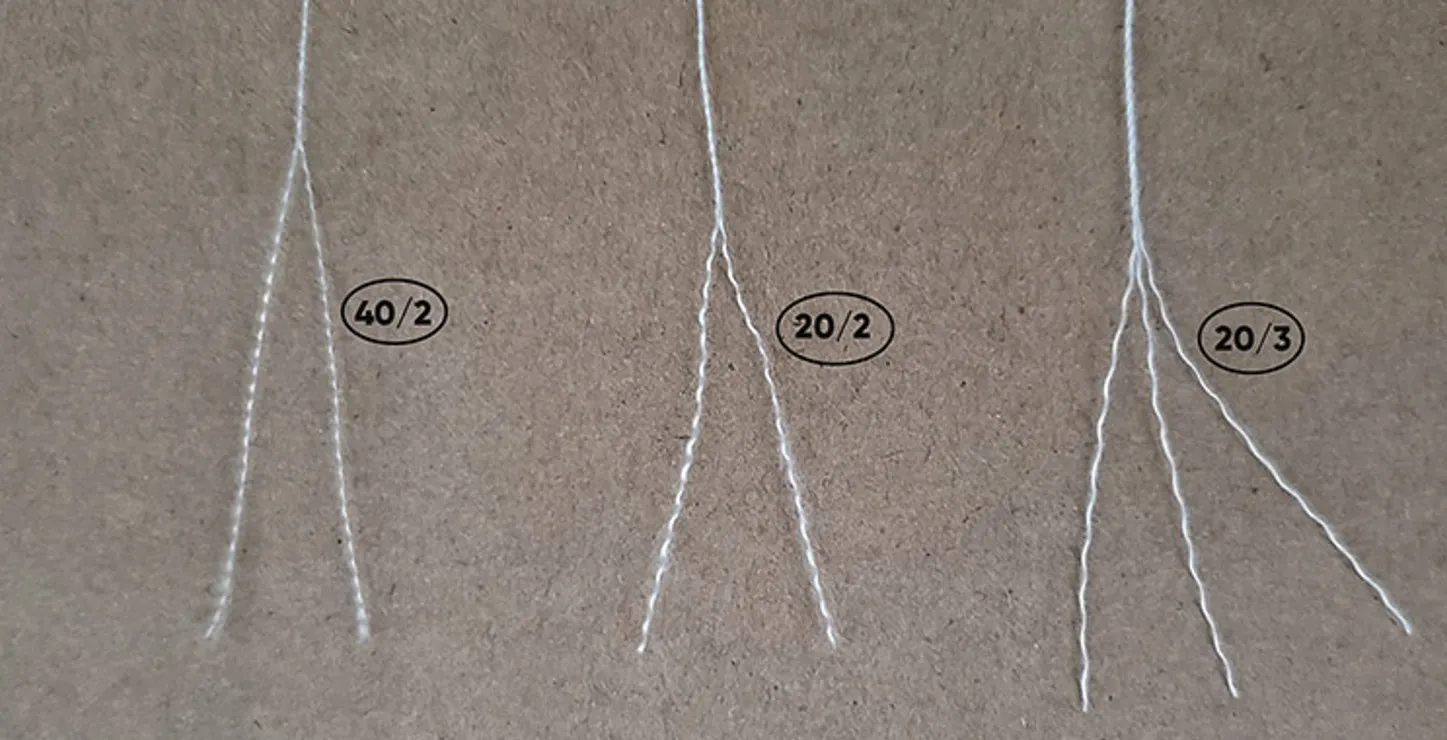

2) Thread Size (Practical Reference)

Sizing varies by supplier system, so treat this as guidance, not a strict conversion:

- Fine (for very light fabrics): chiffon, organza, thin silk

- Medium: regular silk, silk blends, taffeta, premium linen

- Thicker: decorative stitching, heavier embroidery looks

Don’t lock your spec to a single number without swatching. Two suppliers can label size differently. Always approve by real stitch sample.

3) Needle Selection

- For woven silk and delicate wovens: Microtex/Sharp needles give cleaner penetration and reduce snagging

- For silk knits or stretch fabrics: Ballpoint needles reduce yarn damage

4) Stitch Length Guidance

- Regular seams: 2.5–3.0 mm

- Decorative topstitch: 3.0–3.5 mm

Silk Thread vs Polyester, Nylon, Cotton, Core-Spun

Silk thread often sounds like the premium answer, but for many products, it’s the wrong choice. If your garment faces frequent washing, sweat, stretching, or abrasion, polyester, nylon, or core-spun can outperform silk while still looking clean. The goal isn’t to pick the most expensive thread—it’s to pick the one that delivers the best customer experience and lowest complaint rate. Here’s how they truly compare. Here’s how silk compares, from a brand decision standpoint:

- Silk: best for luxury appearance and refined hand-feel

- Polyester: best for durability and general apparel mass production

- Nylon: best for extreme strength and technical products

- Cotton: best for natural aesthetics and high-heat tolerance

- Core-spun: strong “hybrid” choice good durability with a more natural look

If you want a luxury look but still need strong performance, core-spun often beats pure silk in commercial reality.

| Thread type | Surface / look | Strength & abrasion | Stretch / elasticity | Wash & colorfastness | Heat / pressing tolerance | Best use cases | When to avoid |

|---|---|---|---|---|---|---|---|

| Silk (filament / spun) | Natural sheen, “quiet luxury” stitch line | Medium (good for natural fiber, weaker than synthetics) | Low–Medium | Good if cared for, more sensitive to harsh wash | Low–Medium (avoid harsh heat/chemicals) | Ao dai, couture, silk blouses, eveningwear, hand embroidery, premium finishing | Heavy stress seams, sportswear, outdoor/sweaty use, harsh wash programs, heavy denim/canvas |

| Polyester (PE) | Slight sheen to matte (depends on finish) | High (very reliable) | Medium | Very good (mass production friendly) | Medium (can gloss/melt at high heat) | Everyday apparel, industrial production, general seams, most categories | Ultra-high heat finishing, “all-natural” storytelling (some brands avoid) |

| Nylon | Often shinier | Very high (excellent abrasion) | High | Good | Medium | Bags, shoes, technical goods, heavy-duty stitching, bar-tacks | Lightweight luxury wovens (may look too shiny), high-heat processes |

| Cotton | Matte, natural | Medium | Low | Good with gentle wash | High (doesn’t melt) | Natural-look garments, quilting, heat-heavy finishing, heritage aesthetics | High-friction/abrasion products, heavy stress seams needing max strength |

| Core-spun (poly core + cotton/poly wrap) | More “natural” look than pure PE | Very high (strong + stable) | Medium | Very good | Good | Best “balanced” choice: fashion that needs strength + nicer look; premium RTW seams | If you need the true silk luxury hand-feel for visible decorative stitching |

Why Luxury Brands Like Silk Thread

Silk thread isn’t a durability upgrade so why do luxury brands still use it? Because luxury is often about sensory details: the glow of the stitch, how the seam sits on delicate fabric, and how the garment feels on skin. In the right application, silk thread supports craftsmanship and aesthetic control better than many synthetics. In the wrong application, it’s just higher cost with higher risk. Silk thread is chosen because it changes how a garment presents:

- Stitching looks finer and calmer (less harsh line)

- The thread blends beautifully into silk, satin, chiffon, organza, high-end linen/ramie

- Handwork (like couture finishing or embroidery) looks more “crafted,” less industrial

If your customer is paying for “luxury details,” silk thread is one of those details they won’t name, but they will feel.

Conclusion: Is Silk Thread Right for Your Brand?

Silk thread is a premium tool for premium storytelling. It delivers a softer, more luxurious stitch line and supports hand-finished details that elevate perceived value. But it costs more and doesn’t automatically improve durability especially in high-stress, high-wash, or sun/sweat-heavy use cases. If your product is built around elegance, softness, and refined craftsmanship, silk thread can be a powerful choice. If your product must survive rough daily wear, consider blending strategies (silk for visible finishing, stronger thread for stress seams) or alternatives like core-spun.