Polyester vs. Nylon Sewing Thread: What’s Different, and When to Use Each

Polyester and nylon threads can look similar on a cone, but they behave differently once you stitch, wash, press, and wear the garment. If you pick the wrong one, seams can pucker, melt, lose strength, or break under stress. If you pick the right one, your seam stays smooth, strong, and stable for a long time. Below is a clear, factory-friendly way to choose without guessing.

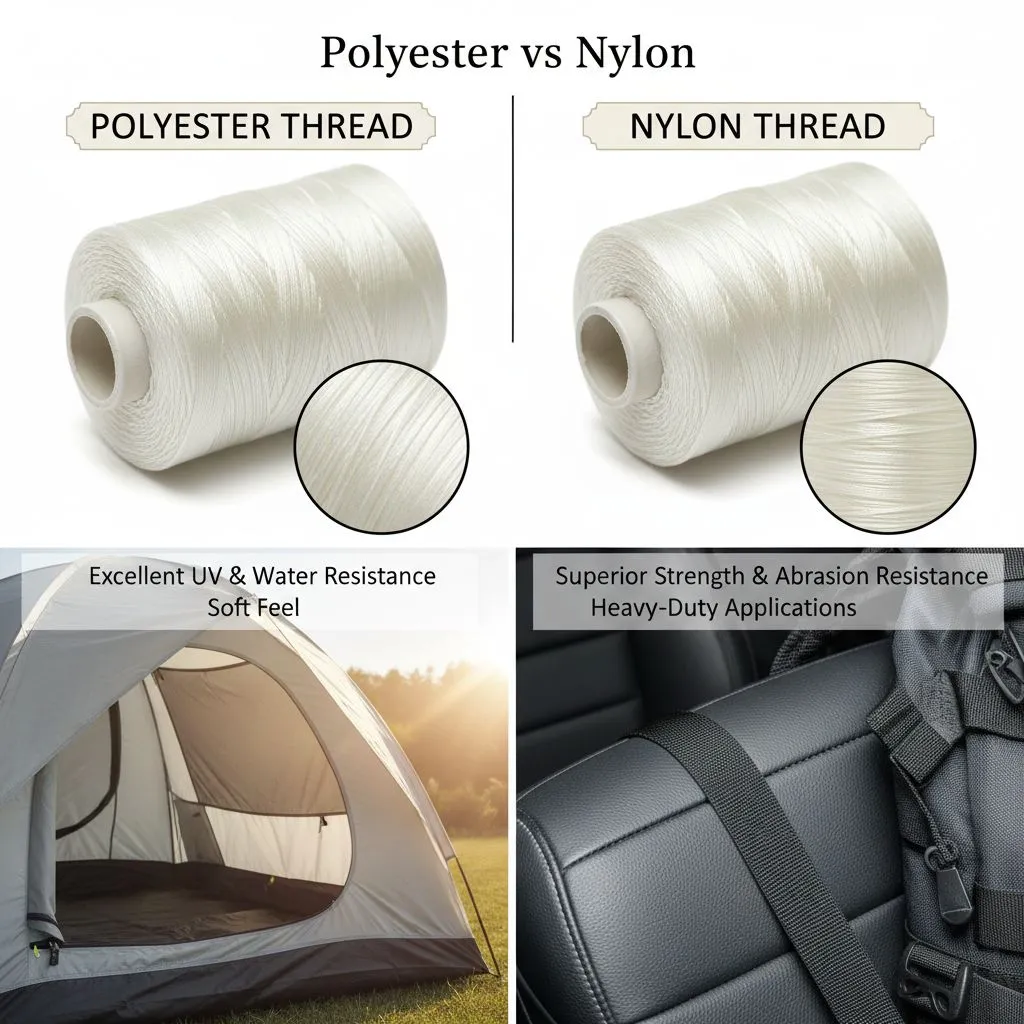

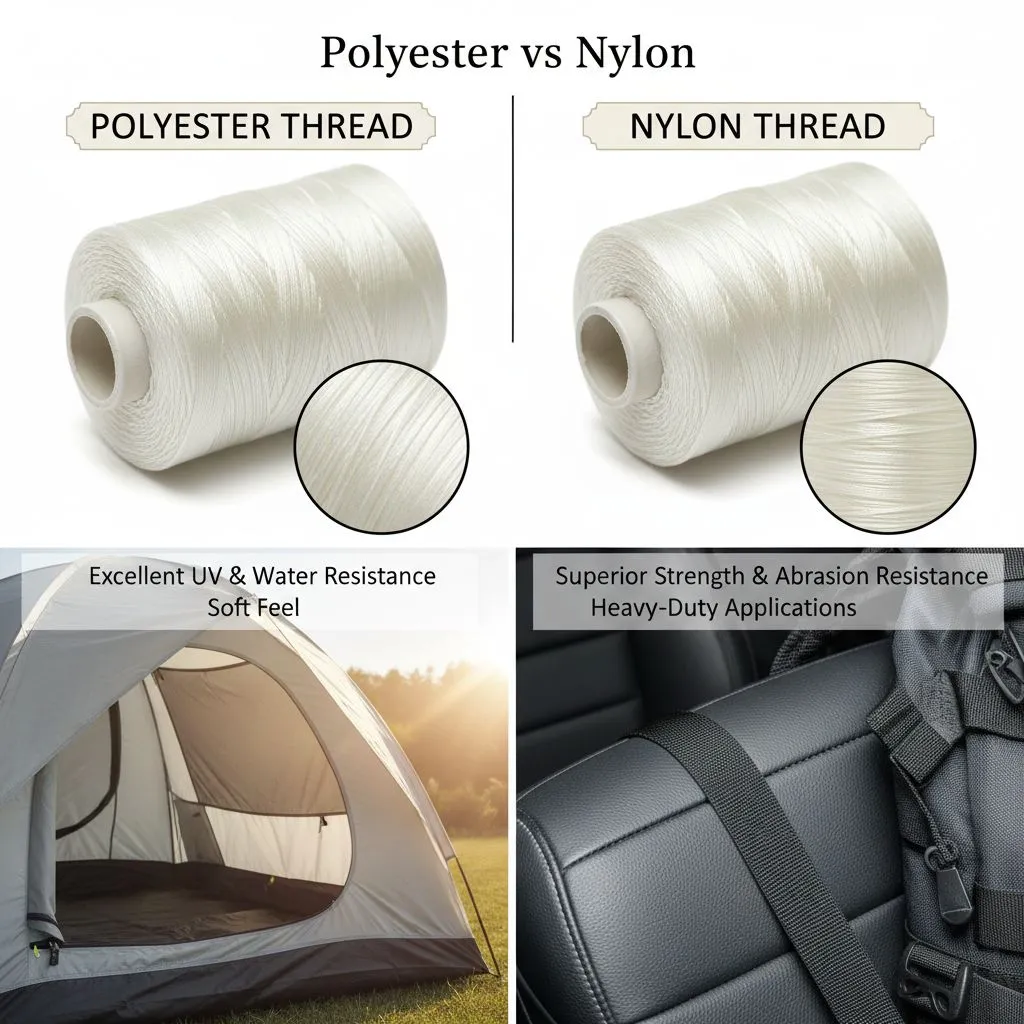

What’s Different: Polyester vs. Nylon Sewing Thread

Quick Compare: Polyester vs Nylon Sewing Thread

| Factor | Polyester | Nylon |

|---|---|---|

| Strength | High | Very high |

| Stretch | Low–moderate | High |

| Seam stability | Excellent | Medium |

| Abrasion resistance | Good | Excellent |

| UV resistance | Excellent | Moderate |

| Heat tolerance | Better | Lower |

| Shrinkage | Very low | Low |

| Moisture absorption | Very low | Higher |

| Seam appearance | Clean, flat | Can be wavy |

| Production risk | Low | Higher if overused |

What each thread “is” (fiber + structure)

Polyester thread is made from polyester fiber (PET) and is built to stay stable in shape. That stability is why it’s a “default” thread in many garment factories. Nylon thread is made from polyamide fiber and is naturally tougher and springier. That spring can be a big win—or a hidden problem—depending on the fabric and finishing.

Key differences:

- Polyester: more dimensionally stable, lower stretch, good “set” in seams.

- Nylon: higher toughness + elasticity, better “give” and recovery.

If you only think “nylon = stronger,” you’ll overuse it. Strength is great, but if the seam stretches more than the fabric, you can get waviness, seam grin, or shape change.

Strength and stretch behavior (how seams act under stress)

A seam fails in real life because of repeated pulling, not one single hard tug. Polyester usually has enough strength for most apparel seams, and it doesn’t keep stretching over time. Nylon is often stronger and more elastic, so it handles shock loads and flexing better. But that same elasticity can make seams look less crisp on stable woven fabrics.

Practical meaning:

- Choose polyester when you want clean, stable seams (shirts, woven outerwear, uniforms, most knits).

- Choose nylon when the product needs high flex + recovery (bags, straps, heavy-duty items, some performance gear).

Abrasion resistance (rubbing, scraping, friction)

Abrasion is what happens when thread rubs on fabric, skin, hardware, or the ground—again and again. This is why some seams break even when the thread “tested strong” at the start. Nylon usually wins on abrasion resistance, especially in harsh use. Polyester is still good, but it’s typically not the top choice for constant rubbing zones.

Use nylon more often for:

- Bags, backpacks, luggage seams

- Webbing, straps, belt loops, tactical/workwear zones

- Items that drag, scrape, or see hardware contact

UV + weather resistance (sunlight and outdoor aging)

Sunlight can quietly weaken thread until it snaps months later. If your product sits in sun—outdoor workwear, awnings, marine gear UV resistance matters a lot. Polyester is generally the safer pick for UV exposure. Nylon can degrade faster in strong UV unless it’s specifically UV-stabilized.

Rule of thumb:

- Outdoor + sun = polyester first, unless you have a UV-stabilized nylon spec you trust.

Chemical and moisture behavior (sweat, detergent, oils, cleaning)

Thread doesn’t just face water it faces detergent, softener, sweat salts, oils, and sometimes industrial washing. Polyester tends to hold up well across many everyday chemicals and washes. Nylon is tough, but it can be more sensitive to certain chemicals and can absorb more moisture than polyester. That moisture uptake can slightly change how seams feel and behave.

Factory reality check: If the garment will be heavily laundered (uniform programs), polyester is often the safer “repeatable” choice.

Heat tolerance and finishing (pressing, fusing, garment dye)

Heat is where many thread choices get exposed fast—pressing, tunnel finishing, fusing, and hot drying. Polyester generally tolerates higher finishing temperatures than nylon in typical apparel workflows. Nylon can soften or deform sooner, especially if the process runs hot or inconsistent. If your finishing is aggressive, thread heat performance matters as much as seam strength.

When polyester is safer:

- Heavy pressing, hot dryers, strong fusing schedules

- Styles where seam imprint or distortion is unacceptable

Saying “polyester tolerates higher temperatures” is true in practice but don’t treat it as unlimited. Bad press settings can still damage polyester thread, especially fine ticket sizes.

Seam appearance and “hand” (how it looks and feels)

Seams are judged by the eye first: straight, flat, no puckers, no waviness. Polyester’s lower stretch helps seams stay neat on stable woven fabrics. Nylon’s elasticity can sometimes create subtle seam waviness on light or crisp fabrics. On the other hand, nylon can feel smoother and more forgiving in some heavy constructions.

- Choose polyester when: You need sharp seam lines (shirts, tailored looks, crisp woven fabric)

- Choose nylon when: The product is thick, rugged, and movement-heavy (gear, heavy-duty, high abrasion)

Best-use guide (fast selection by product)

Most factories don’t have time for long debates—so use a simple matching method. Start with the fabric type, then the stress level, then the finishing heat. If two options look “fine,” pick the one that reduces risk in your finishing and end-use. Here’s a clean map you can apply quickly.

Polyester thread is usually best for:

- Shirts, blouses, dresses (woven)

- Outerwear and general apparel production

- Most knitwear seams where stability matters

- High-heat finishing, fusing, heavy laundering programs

- Outdoor items where UV exposure is a concern

Nylon thread is usually best for:

- Bags, backpacks, straps, webbing

- Heavy-duty items with abrasion + repeated flex

- Products needing “give” and shock resistance

- Areas that get dragged, scraped, or hit hardware

A Simple Decision Checklist:

If you want fewer seam problems, decide in the same order every time. First: what will the customer do to it? Second: what will your finishing line do to it? Third: does the fabric stretch, or is it stable? This checklist prevents the common mistake of choosing thread only by “strength.”

Pick polyester if most answers are YES:

- High heat pressing/fusing/drying

- Outdoor UV exposure

- Crisp seam appearance is critical

- Fabric is stable (woven) and you want low seam stretch

- Heavy laundering is expected

Pick nylon if most answers are YES:

- Constant abrasion/rubbing

- Heavy-duty use, gear, straps, webbing

- Repeated flexing and shock loads

- You need extra elasticity and recovery

Conclusion / Final Words

Polyester thread is the workhorse: stable, UV-strong, wash-friendly, and usually safer under hot finishing. Nylon thread is the toughness specialist: stronger, more elastic, and often better when abrasion and flex are the real enemies. The mistake is thinking one is “better” in all cases. Choose based on end-use stress, finishing heat, and fabric behavior—and your seams will look better and fail less.

Our Contact Information – MEKONG GARMENT FACTORY

- Vietnam Phone: +84 947 729 829

- WeChat: +84 947 729 829

- WhatsApp: +84 947 729 829

- Email: hanh@kimmy.vn