In international garment shipping, the hanger is not a minor accessory. It directly affects garment shape, wrinkle level, space efficiency, and first visual impression at arrival. A wrong hanger can cause shoulder marks, stretching, creasing, or poor presentation at retail. A correct hanger protects the product, reduces rework, and supports brand value. The best hangers for garment shipping balance four factors: durability, garment protection, space efficiency, and cost control. Below are the five hanger types most commonly used in global apparel logistics, with clear guidance on when and why each one works.

=> Related Article: Tech Pack to Finished Garments: A Complete Production Timeline Guide (8–16 Weeks)

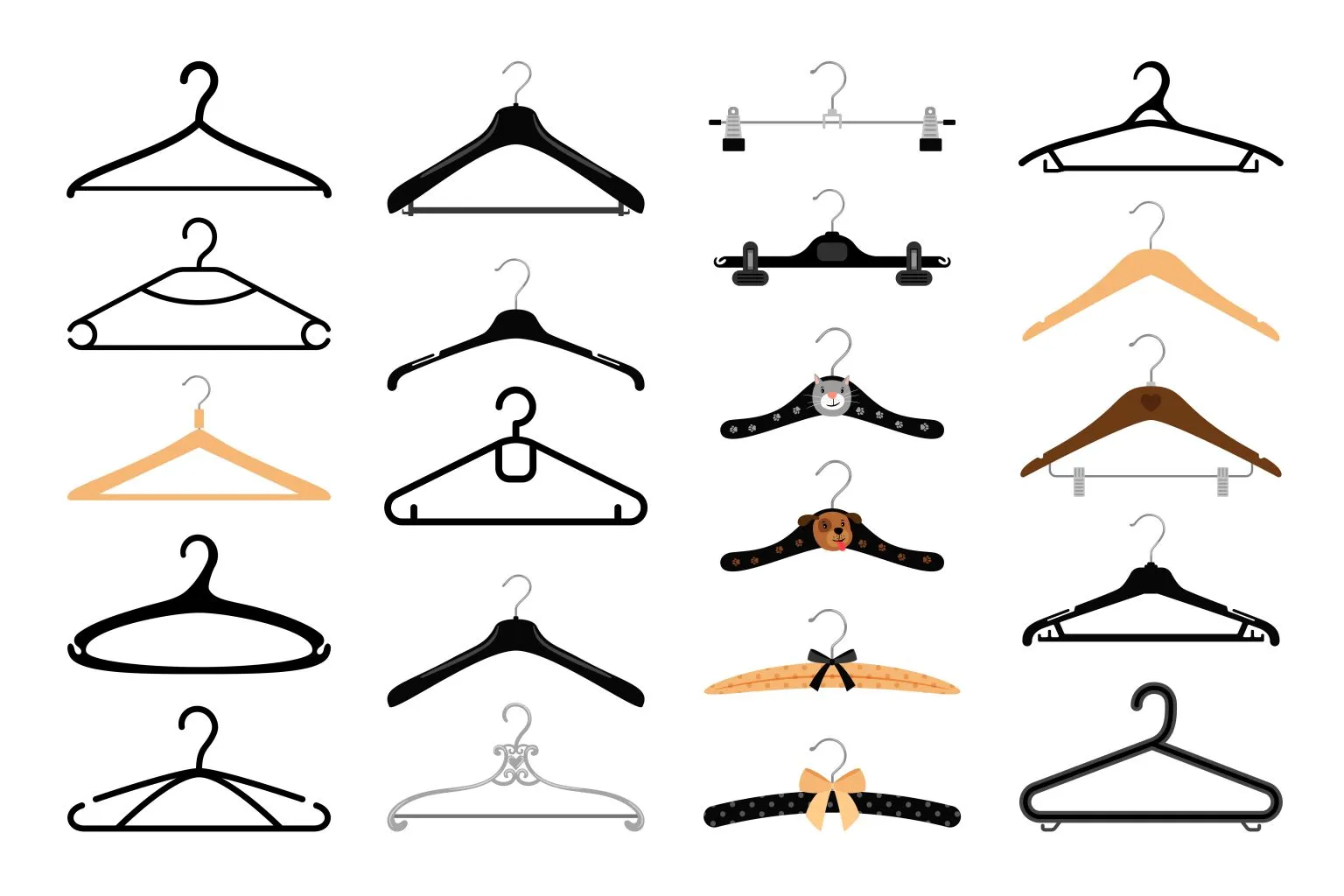

Top 5 Hangers for Garment Shipping

Plastic Hangers

Plastic hangers are the most widely used option in global garment exports. They are lightweight, affordable, and suitable for high-volume shipments. These hangers perform well during long sea freight because they resist moisture and do not rust. Their consistent shape allows efficient carton packing and stable stacking during transport.

Best use cases

- T-shirts and knitwear

- Polo shirts

- Casual blouses and tops

- Fast-fashion bulk orders

Advantages

- Low unit cost

- Lightweight, reducing freight cost

- Resistant to humidity

- Easy to source globally

Limitations

- Standard plastic is not eco-friendly

- Lower perceived value for premium brands

Recycled and biodegradable plastic hangers are increasingly used to meet sustainability requirements without changing packing systems.

What Can I Do With Old Plastic Coat Hangers

Old plastic coat hangers do not have to go straight into the trash. The first step is to check the recycling code on the hanger, remove any metal hooks or clips, and take them to a recycling or materials recovery center that accepts rigid plastics. If recycling is not available, old plastic hangers can be reused in practical or creative ways, extending their life and reducing waste.

=> Related Article: How Does a Prototype Sample Affect My Clothing Production Cost?

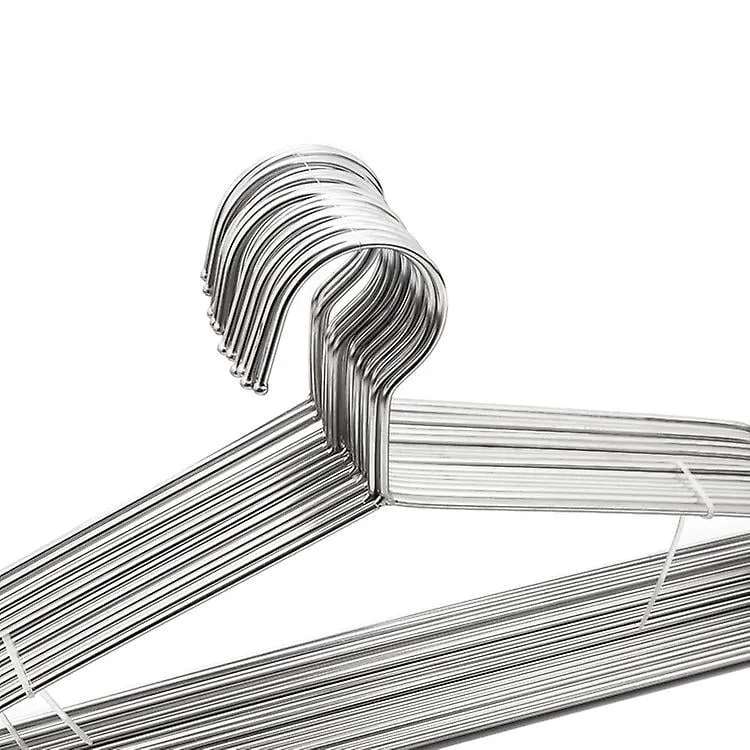

Metal Hangers

Metal hangers, especially wire hangers, are thin and space-saving. They are commonly used when shipment volume and carton density are critical. Because of their slim profile, metal hangers allow more garments per carton. This reduces shipping cost per unit, which is important for price-sensitive programs.

Best use cases

- Shirts and woven tops

- Lightweight blouses

- Dry-clean-only garments

- High-density bulk shipments

Advantages

- Very low cost

- Minimal space usage

- Easy to stack and bundle

Limitations

- Can bend under heavy weight

- Not suitable for coats or tailored items

- Lower protection for garment shape

Metal hangers work best when garments are light and price efficiency is the main priority.

Wooden Hangers

Wooden hangers are the preferred choice for premium and luxury apparel. They provide strong support and help garments maintain their intended shape throughout transit. Their wider shoulder design prevents sagging and deformation, especially for structured garments. Many high-end brands require wooden hangers to ensure products arrive retail-ready.

=> Related Article: How Do Tech Packs Improve Your Apparel Quality Control?

Best use cases

- Suits and blazers

- Coats and heavy outerwear

- Tailored jackets

- Luxury fashion shipments

Advantages

- Excellent shape support

- High perceived quality

- Strong and durable

Limitations

- Heavier, increasing freight cost

- Higher unit price

- Less space-efficient

For premium brands, the added cost is often justified by better presentation and reduced garment damage.

Padded Hangers

Padded hangers are designed for delicate fabrics that are easily stretched, creased, or damaged. The soft padding distributes weight evenly and eliminates pressure points. They are commonly used for special collections where garment condition is more important than packing density.

Best use cases

- Silk and satin dresses

- Lingerie

- Evening wear

- Delicate fashion pieces

Advantages

- Excellent protection for fragile fabrics

- Prevents hanger marks and stretching

- Maintains garment drape

Limitations

- Bulky, reducing carton efficiency

- Higher cost

- Not practical for large-scale shipments

Padded hangers are best reserved for low-volume, high-value garments.

Clip Hangers

Clip hangers are designed specifically for bottom garments. Instead of folding, garments hang vertically, reducing creases and saving preparation time at retail. The adjustable clips allow flexibility for different garment widths, making them suitable for varied product ranges.

Best use cases

- Trousers

- Skirts

- Shorts

- Sets shipped separately

Advantages

- Prevents fold creases

- Improves retail readiness

- Adjustable for different sizes

Limitations

- Clips must be well-padded to avoid marks

- Slightly heavier than wire hangers

Clip hangers are especially useful for brands that prioritize fast store setup and minimal steaming.

Conclusion / Final Words

Hanger selection directly affects garment condition, shipping efficiency, and brand perception. There is no single best hanger for all products. The correct choice depends on garment type, shipment volume, cost target, and brand positioning.

- Plastic and metal hangers support cost-efficient bulk shipping

- Wooden hangers protect structure and elevate premium apparel

- Padded hangers safeguard delicate fabrics

- Clip hangers keep bottom garments wrinkle-free and retail-ready

Choosing the right hanger is a practical decision with measurable impact on quality, cost, and customer satisfaction.

Our Contact Information – MEKONG GARMENT FACTORY

- Vietnam Phone: +84 947 729 829

- WeChat: +84 947 729 829

- WhatsApp: +84 947 729 829

- Email: hanh@kimmy.vn