The length of a thread roll depends on the type of thread, purpose of use and manufacturing specifications. Typically, the length can vary from a few hundred metres to tens of thousands of metres. In garment sewing, the roll length is a key factor that directly affects efficiency and productivity. Depending on the use — from home sewing to industrial production each roll type has its own length and characteristics. In this article, we will explore the common types of thread rolls and the average lengths of each type, so you can choose the most suitable product.

3 Common Types of Sewing Thread on the Market

Domestic Sewing Thread: 300 – 500 metres.

Domestic sewing thread is designed for simple sewing needs at home. The length of each roll is typically moderate, around 300–500 metres, with an average of about 400 metres per standard roll.

- Common length: ~300–500 m.

- Feature: Used for home sewing machines or hand stitching. The core diameter is small, easy to store. Material is usually polyester or polyester-cotton blend, colour-fast and less prone to fuzzing.

- Example: One roll might be enough to sew about 6–8 standard garments for home use.

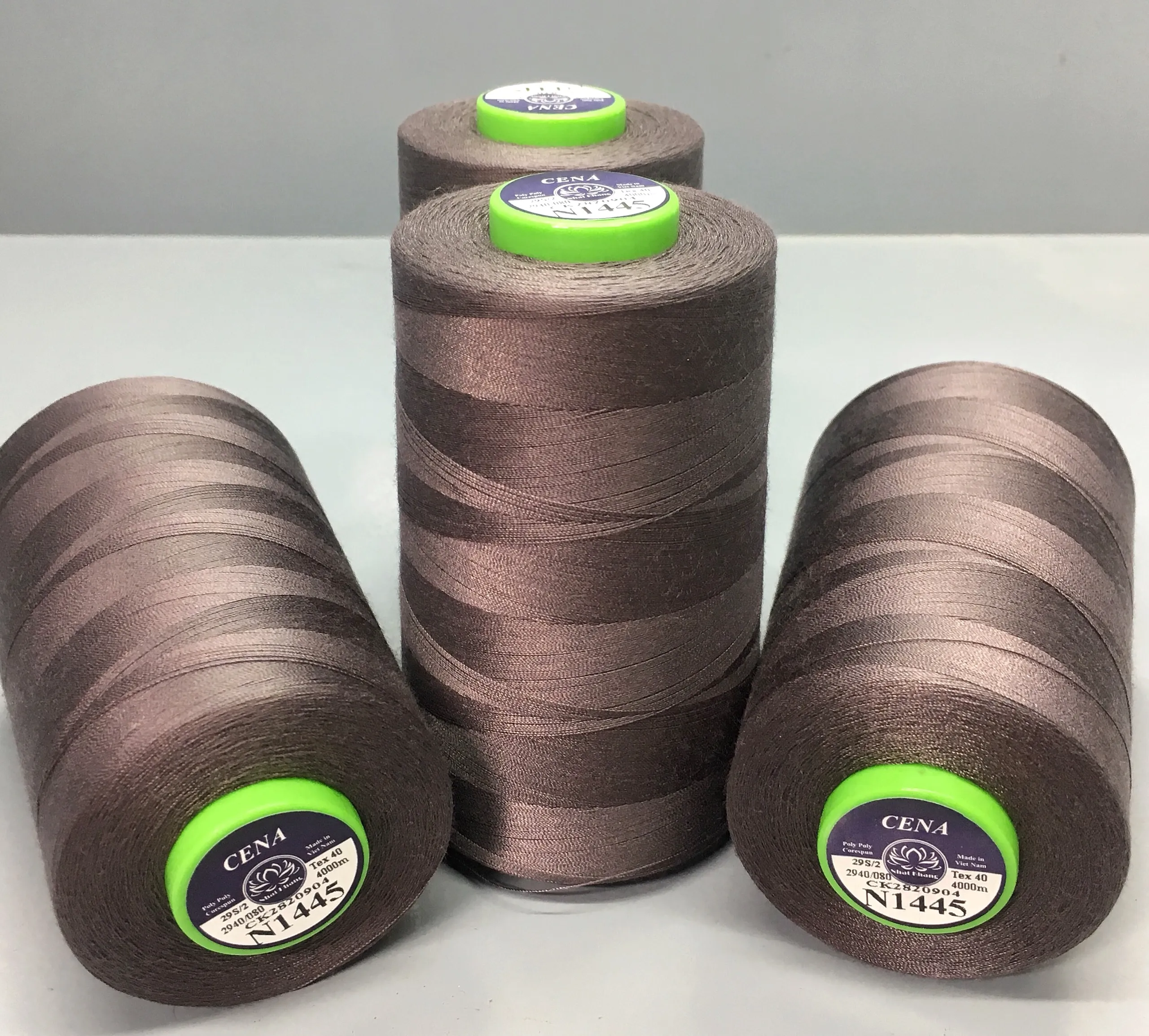

Medium-scale Industrial Sewing Thread: 2,500 – 5,000 metres.

This type of industrial sewing thread is used in small to medium garment factories, requiring good durability and stable performance. Each roll typically has a length of 2,500–5,000 metres, which reduces the frequency of roll changes and saves time in production. The thread is tightly twisted, can withstand continuous machine speed without breaking. This is a balanced choice between cost and productivity for batch production.

- Common length: 2,500–5,000 m.

- Feature: Used in small/medium factories for mass production though not requiring very large rolls. Many colour options. Suitable for high-speed industrial machines. High twist and strength to endure continuous usage.

- Example: A 5,000 m roll could sew more than 800 standard T-shirts.

Large-scale Industrial Sewing Thread: 10,000 – 20,000 metres.

This large-scale industrial thread is an “indispensable assistant” in export garment factories or continuous production lines. With lengths from 10,000 up to 20,000 metres (or more) per roll, this type helps minimise downtime for roll changes, thereby increasing machine efficiency. The core is often made of plastic or hard paper, ensuring the thread is wound tightly and does not tangle during use. This is the optimal solution for continuous production, meeting large‐volume orders in short time.

- Common length: 10,000–20,000 m (even more if using a special large core).

- Feature: For export factories, continuous production over many hours. Plastic or rigid paper core. The thread is wound tightly and evenly. Minimises roll changes, increases machine up-time.

- Example: One 20,000 m roll might be enough to sew over 3,000 pairs of jeans.

Factors That Affect the Length of a Thread Roll

The length of a thread roll is not only determined by production scale, but also influenced by factors such as the material of the yarn, the thickness of the thread and the weight of the roll. This explains why two “industrial” rolls might still differ in length depending on use (for example sneakers or backpacks use shorter rolls than light clothing). Understanding these factors helps users choose the right roll, avoid waste, and optimise efficiency.

- Purpose of use: Home → short roll; Industrial → long roll.

- Material: Polyester, nylon can be wound longer than pure cotton.

- Weight: Large industrial roll might weigh 350–500 g (e.g., 410 g for a 20,000 m roll).

- Thread thickness: Thinner thread → longer roll; Thicker thread → shorter length for same spool size.

Conclusion / Final Words

Choosing the right roll length of thread not only affects production efficiency but also impacts product quality and operating cost. For home sewing, a shorter roll makes it easier to manage colour changes and storage; whereas in industrial settings, a longer roll helps save time changing rolls and keeps the line running. Moreover, factors like thread material, thickness, and roll weight also play major roles in selecting the proper specification. Understanding the features of each type of thread roll will help you optimise your sewing process, save cost and improve productivity.