Why an Estimate Without a Sample Is a Risk for Your Brand

You have a new design in hand. You send sketches, a tech pack, or even just reference photos to several factories. One reply stands out. The price is much lower than expected, and the delivery time sounds fast. It feels like a win. This is the exact moment many brands make a costly mistake.

They treat an estimate as a price, commit to production, and skip the sampling stage. What looks like a shortcut is actually a trap. An estimate without a physical sample is not a confirmed cost. It is a number built on assumptions, not proof. When those assumptions break, the brand pays the price in money, time, and reputation. An estimate without a sample is not a bargain. It is a risk multiplier.

Why Estimates Without Samples Are Fundamentally Unreliable

At its core, an estimate created without a sample is based on incomplete information. No matter how experienced a factory is, it cannot see how your design behaves in the real world until it is physically made.

Without a sample, the factory is guessing:

- How much fabric the design truly consumes

- How long the garment actually takes to sew

- Whether the design is stable, repeatable, and scalable

These guesses may be optimistic to win your order or conservative to protect the factory. Either way, the number is unstable. That instability always shows up later, when changes become expensive. In simple terms, you are buying a promise, not a product.

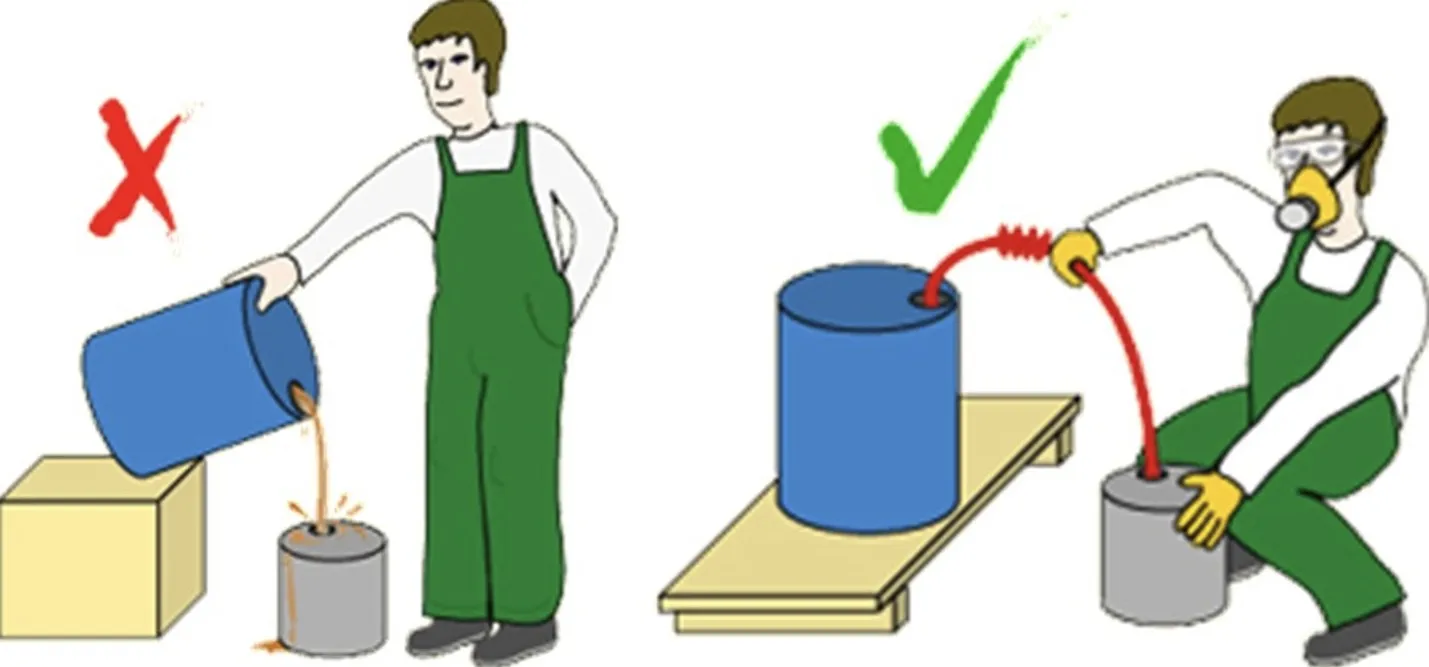

=> How Skipping the Sample Phase Inflates Total Landed Cost: The initial low estimate often looks attractive because the true costs are hidden. Those costs do not disappear. They simply surface later, when they are far more expensive to fix. Sampling is the cheapest place to fail.

=> How an Approved Sample Protects Quality and Compliance: An estimate is just a number. An approved sample is a physical contract. In professional manufacturing, the approved Pre-Production Sample (PPS) becomes the benchmark for all inspections.

The Sample as the “Golden Standard”

During bulk inspection:

- Finished garments are compared directly to the sealed PPS

- Deviations are measurable and enforceable

Without this benchmark:

- Factories can claim compliance

- Inspectors lack authority

- Brands have no objective grounds for rejection

Estimates vs. Samples

You often receive a neat estimate but without a sample you’re buying projections, not proof: estimates regularly shift by 10-40% once a physical sample is produced, because fabric waste, markers and actual SAMs reveal themselves only in three dimensions. When you commit on that number, you lock in assumptions-fabric yield, trim costs, sewing sequence-that routinely change after the first sample, turning a perceived saving into an unexpected cost driver.

The Importance of Sampling

Sampling forces reality onto the quote: a Pre‑Production Sample (PPS) sets the standard for inspections and confirms actual fabric consumption, trims, and SAM. You pay a small upfront fee-often 0.5-2% of an order-to avoid downstream losses that can exceed 5-20% through rework, price revisions or missed seasons for a 5,000+ unit production. That one physical garment protects your margin and timeline.

Common Misconceptions

You may believe a low estimate equals a final price, that lead times are fixed, or that digital markers fully replace hands-on testing. Those assumptions hide risk: factories use analogous styles to price jobs, and without a sample you lose visibility into real labor minutes, yardage, and makeability-so the “final” cost often changes after sampling.

For example, a shirt quoted at $4.00/unit can jump to $6.00/unit after a sample shows extra lining, longer assembly (SAM rising from 20 to 35 minutes), and a larger marker yield; on a 10,000 unit run that’s an unexpected $20,000 increase. When you skip sampling you trade small upfront certainty for the far larger risk of cost creep, timeline slippage, and damaged retail commitments.

What Critical Information Is Missing From a Sample-Less Estimate?

A quote created from sketches or a tech pack is an exercise in extrapolation. The factory must fill in gaps with assumptions, because many details only reveal themselves during physical construction. A sample-less estimate is built on a fragile structure of guesses. Below are the three biggest pillars of uncertainty.

Factor 1: Fabric Consumption and Material Cost

Fabric is usually the largest cost component in apparel. Small miscalculations here can quietly destroy margins. Without a sample, fabric cost is almost always wrong.

What the Estimate Assumes, The factory typically assumes:

- A standard fabric width

- Average waste percentages

- No pattern matching or directional cutting

These assumptions are based on “similar styles,” not your actual design.

What the Sample Reveals, Once a pattern is made and tested, reality appears:

- Bias cuts can increase waste by 20–30%

- Plaids, stripes, or prints require matching

- Large or irregular pattern pieces reduce marker efficiency

Until a marker is created and validated, real fabric usage is unknown. A digital marker helps, but only a physical sample confirms the truth.

Factor 2: Labor Time (SAM – Standard Allowed Minutes)

Labor cost is not about garment type. It is about construction detail. Two shirts can look similar and take radically different amounts of time to make.

What the Estimate Assumes, Factories often assign SAM values from databases:

- “Standard shirt”

- “Basic jacket”

- “Simple dress”

These values ignore the nuances that slow production.

What the Sample Reveals, During sampling, the sewing sequence becomes clear:

- Concealed plackets

- Specialized seam finishes

- Complex cuffs, collars, or facings

A design estimated at 20 minutes may take 35 minutes in reality. That difference compounds across thousands of units. Without a sample, labor cost is theoretical.

Factor 3: Makeability and Hidden Construction Complexity

Some designs look simple on paper but fight back when sewn. Makeability can only be tested in three dimensions.

What the Estimate Assumes, The factory assumes:

- Fabric behaves as expected

- Layers stack cleanly

- Standard machines are sufficient

What the Sample Reveals, Sampling exposes issues that sketches cannot:

- Fabric puckering at seams

- Interlining instability

- Zippers that refuse to lie flat

- Designs requiring special machines or skills

Sometimes the factory discovers it cannot make the product efficiently at all. At that point, prices change, timelines shift, or subcontracting becomes necessary.

Assumption vs. Reality: A Simple Comparison

| Cost Component | Estimate Assumption | Sample Reality |

|---|---|---|

| Fabric | 1.5 yards @ $3 = $4.50 | 2.1 yards due to bias cut = $6.30 |

| Labor | 25 minutes (standard shirt) | 38 minutes due to complex placket |

| Trims | Generic buttons = $0.50 | Custom buttons + mold fee |

| Feasibility | “Yes, we can make it” | Design needs revision |

Cost Creep Without Sampling

Post-Order Price Revisions, After committing, the factory produces a sample and announces:

- Higher-grade fabric required

- More labor than expected

- Additional trims or processes

At this stage, your negotiating power is weak. Time and momentum are already lost.

Quality Failure Costs, If you accept a lower standard to protect price:

- Returns increase

- Discounts erode margins

- Brand trust suffers

These losses are rarely tracked accurately, but they are real.

Delay Domino Effect, Without sampling, problems appear during bulk production:

- Line stoppages

- Rework

- Missed shipping dates

Missing a selling season is often the single most expensive failure a brand can experience.

Conclusion / Final Words

An estimate without a sample is a fantasy price for a product that does not yet exist. It is useful only as a starting point, never as a commitment. The physical sample is what converts:

- Assumptions into facts

- Guesses into data

- Risk into control

Investing in sampling is not an extra cost. It is the foundation of predictable margins, stable timelines, and brand-safe production. Brands that skip this step are not saving money. They are gambling.

Our Contact Information – MEKONG GARMENT FACTORY

- Vietnam Phone: +84 947 729 829

- WeChat: +84 947 729 829

- WhatsApp: +84 947 729 829

- Email: hanh@kimmy.vn