In production, “thread” isn’t just about color or thickness it’s about structure: how the fibers are built into a sewing thread. That structure controls how the thread behaves under the needle, how it looks on the seam, and how well it survives washing, heat, and abrasion. Pick the wrong structure and you’ll see classic problems fast: skipped stitches, seam puckering, lint buildup, or seams that pop on stretch areas.

In this guide, we’ll break down the 5 most common thread structures spun polyester, core-spun, continuous filament, monofilament, and textured (wooly) then match each one to real garment uses (knits, denim, leather goods, invisible hems, activewear). The goal is simple: help you choose a thread structure that works with your fabric, not against it.

Common Types of Thread Structures

Manufacturers produce several distinct structural types to meet specific garment needs. The most frequently used categories include spun polyester, core-spun, and continuous filament threads. Spun polyester feels like cotton and is cost-effective, while continuous filament offers a smooth, glossy finish ideal for leather or heavy-duty fabrics. Selecting the correct type ensures that the thread’s texture complements the fabric rather than fighting against it, preventing issues like seam puckering.

- Spun Polyester is widely used for standard garments due to its low cost and matte finish.

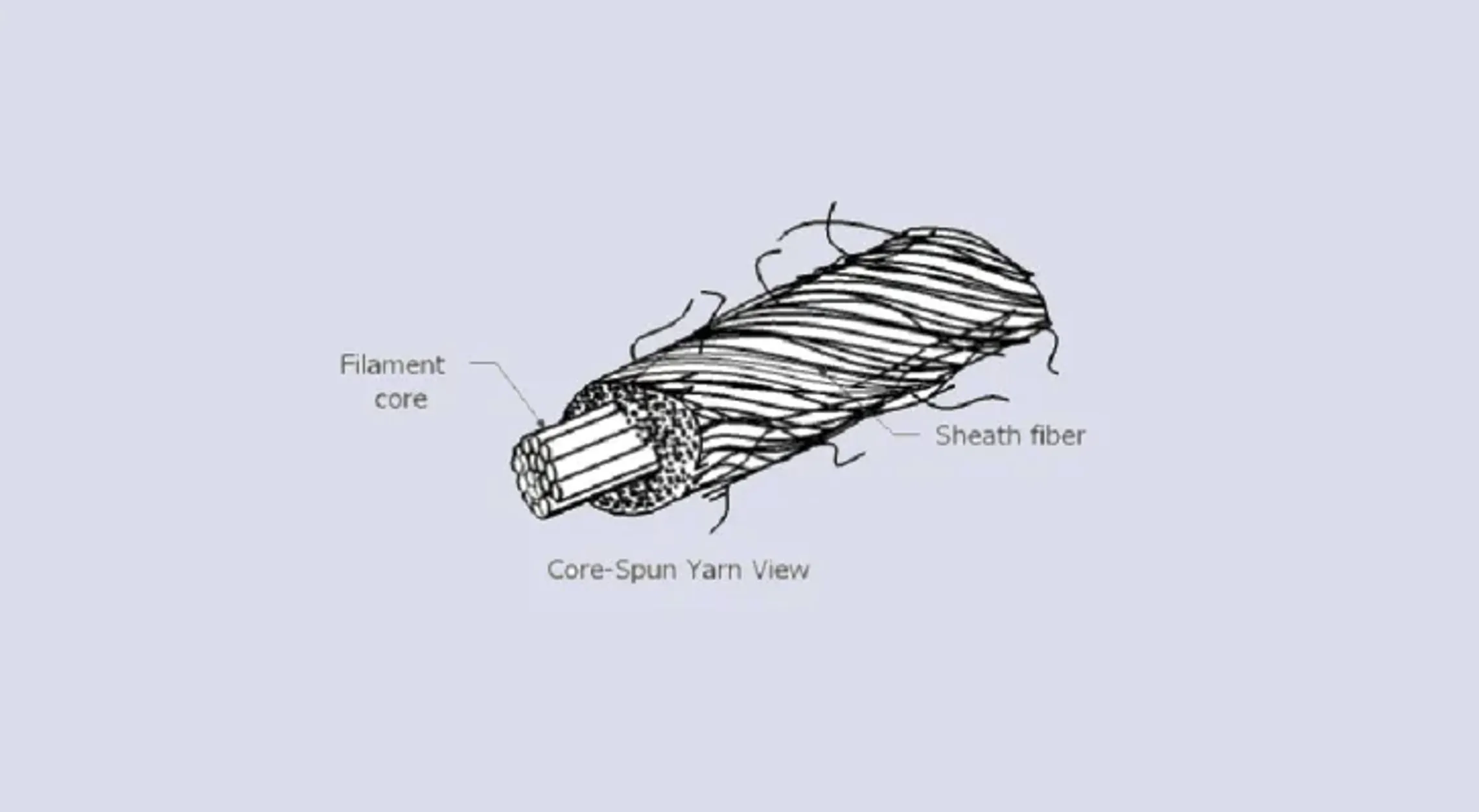

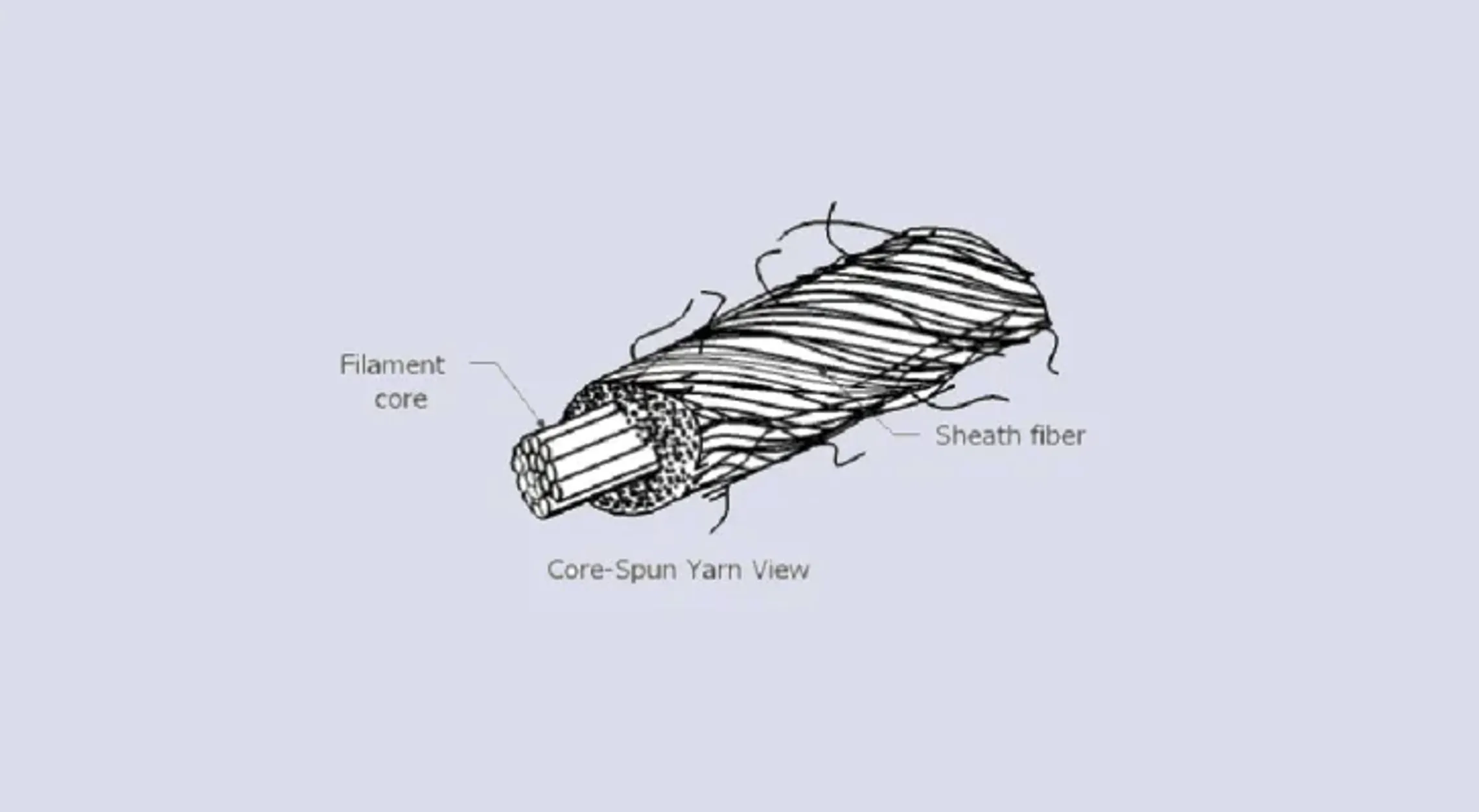

- Core-spun threads provide superior strength for denim and workwear applications.

- Continuous Filament eliminates lint buildup in the machine and offers high tenacity.

- Recognizing these distinctions allows you to match the thread’s physical properties to your specific manufacturing requirements.

=> Read More: Spun Polyester Thread: Best Cost-To-Performance Ratio for Standard, Non-stretch Garments.

| Thread Structure | Key Characteristic |

|---|---|

| Spun Polyester | Fuzzy surface, mimics cotton, cost-effective |

| Core-Spun | High strength core with abrasion-resistant wrapper |

| Continuous Filament | Smooth, glossy, zero lint, high tenacity |

| Monofilament | Single strand, transparent, stiff, low visibility |

| Textured (Wooly) | Soft, high bulk, excellent coverage for seams |

Garment Application & Recommended Structure

When dealing with heavy-duty applications like denim or workwear, core-spun threads are the superior choice because they combine a high-tenacity polyester core with a cotton or polyester wrapper. This wrapper protects the core from needle heat, significantly reducing breakage rates on thick layers. Conversely, for lingerie or swimwear, textured nylon threads provide the necessary softness against the skin and high elasticity to prevent seam cracking when the fabric stretches. Using a standard spun thread on high-stretch garments is a dangerous mistake that leads to immediate seam failure upon wearing.

| Garment Application | Recommended Structure |

|---|---|

| Denim / Jeans | Core-spun (Poly/Cotton) for wash effects |

| T-Shirts / Knits | Spun Polyester for general seams |

| Swimwear / Activewear | Textured Nylon for stretch and softness |

| Leather Goods | Continuous Filament Bonded Nylon |

| Blind Stitching | Monofilament for invisibility |

Final Words / Conclusion

Thread structure sounds like a “small detail,” but in real production it’s a big lever. When you match structure to fabric and use-case, you reduce the stuff that quietly destroys timelines: thread breaks, lint jams, seam puckering, and seams that crack the first time someone moves.

Before you lock a thread, do this quick sanity check:

- If it’s standard woven/regular seams: start with spun polyester (solid cost-to-performance).

- If it’s denim, thick layers, high stress: go core-spun for strength and durability.

- If you want smooth + strong and hate lint buildup: choose continuous filament (especially for heavy-duty and cleaner running).

- If stitches must “disappear”: monofilament works, but remember it can feel stiff don’t use it where comfort matters.

- If it’s stretch, activewear, swim: textured (wooly) nylon is the safer path using a standard spun thread here is asking for seam failure.