8 Common T-Shirt Printing Methods: Pros, Cons, and How to Choose the Right One

For About t-shirt printing method is not just a design decision. It affects cost, durability, production speed, fabric choice, and how professional your brand looks after 10 washes. Many people pick a printing method based on trends or what a supplier recommends. That’s risky. Each technique has clear strengths and very real limits. Choose the wrong one, and you’ll face peeling prints, faded colors, unhappy customers, or wasted budget. This guide breaks down all major t-shirt printing types, compares them honestly, and helps you choose the right method for your actual business goal, not marketing hype.

=> Read More: T Shirts Manufacturing Vietnam | Mekong Garment Factory

Overview T-Shirt Printing Methods Comparison

| Printing Method | Best For | Durability | Setup Time | Fabric Compatibility | Cost |

|---|---|---|---|---|---|

| Screen Printing | Bulk orders, bold designs | Very High | High | Most fabrics | Low for bulk |

| DTG Printing | Small runs, detailed art | Moderate | Low | 100% cotton | Moderate |

| DTF Printing | All-purpose, colorful prints | High | Moderate | Almost all fabrics | Moderate |

| Heat Transfer | Photos, short runs | Low | Low | Wide range | Low |

| Dye Sublimation | All-over prints | Very High | Moderate | Polyester only | High |

| Puff Printing | 3D logos, streetwear | High | High | Cotton & blends | Moderate–High |

| HTV | Personalized items | High | High | Wide range | Low |

| Embroidery | Logos, uniforms | Very High | High | Heavier fabrics | High |

=> Important reality check: Durability depends heavily on ink quality, curing process, and factory skill—not just the method name.

About T-Shirt Printing Methods

The most commonly used t-shirt customization techniques today include:

- Screen Printing

- Direct-to-Garment (DTG) Printing

- Direct-to-Film (DTF) Printing

- Heat Transfer Printing

- Dye Sublimation Printing

- Puff Printing (special effect)

- Heat Transfer Vinyl (HTV)

- Embroidery

Not all of these are equal and some are often misused.

Screen Printing

What is screen printing? Screen printing (also called silkscreen printing) uses a mesh screen and stencil to apply ink layer by layer onto fabric. Each color requires a separate screen. It is one of the oldest and most reliable printing methods and still dominates bulk production.

Best applications

- Large quantity orders

- Bold logos and graphics

- Promotional and corporate t-shirts

- Special effects (puff, metallic, glitter)

Pros:

- Extremely durable when cured correctly

- Lowest cost per unit at high volumes

- Works on cotton, polyester, and blends

- Supports many special ink effects

Cons:

- High setup cost for small orders

- Not ideal for complex, multi-color artwork

Important Notes:

If you’re printing under 50 pieces, screen printing is usually a bad financial choice no matter how “premium” it sounds.

Direct-to-Garment (DTG) Printing

What is DTG printing? – DTG uses inkjet technology to print water-based inks directly onto the fabric, similar to a paper printer.

Best applications:

- One-off or small batch orders

- Highly detailed designs

- Photorealistic artwork

- Print-on-demand businesses

Pros:

- Excellent detail and color gradients

- Soft hand feel

- No screens or setup fees

Cons:

- Lower durability than screen or DTF

- Poor results on polyester

- Slow for bulk production

=-> Notes: DTG looks amazing on day one—but cheap DTG jobs fade fast. Pretreatment quality matters more than most sellers admit.

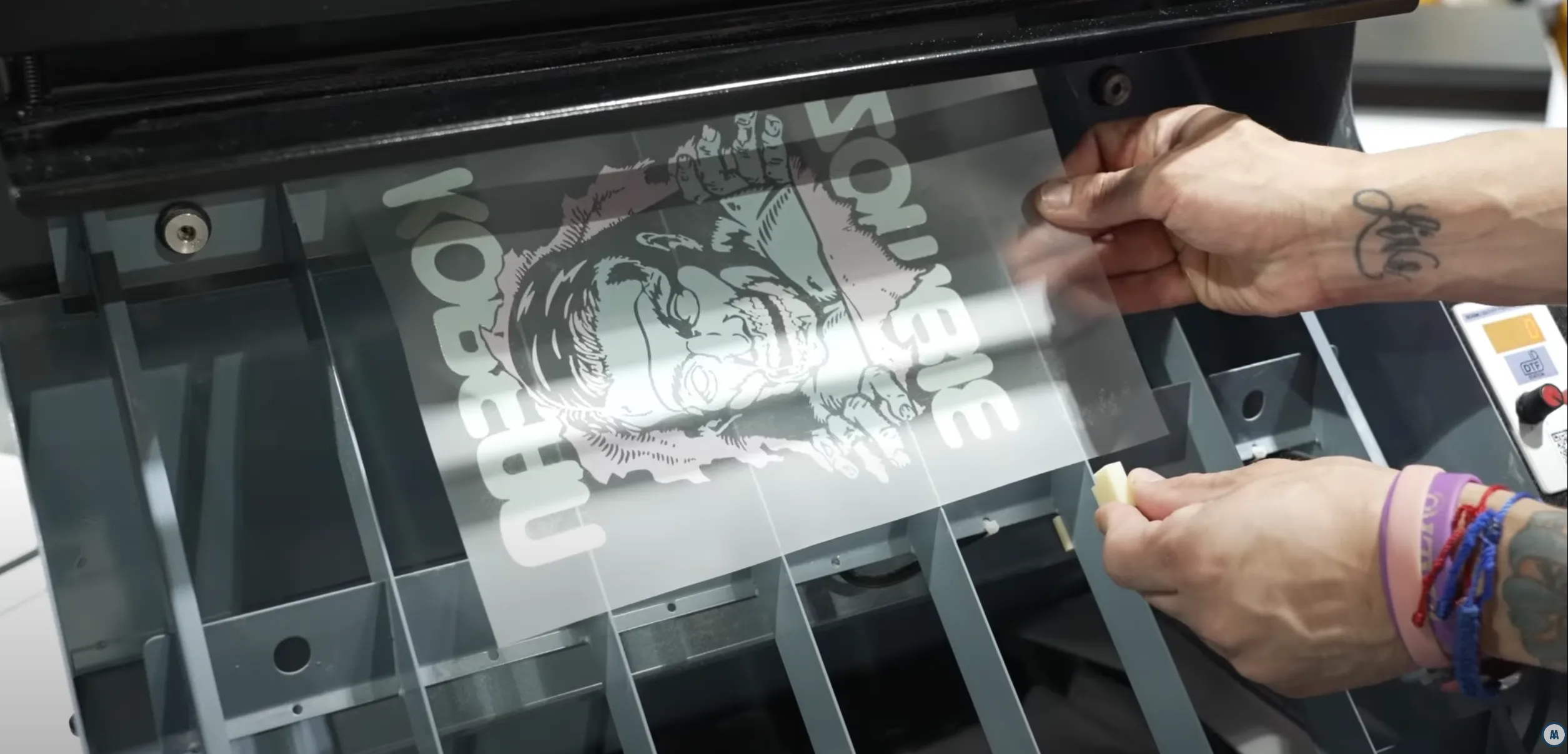

Direct-to-Film (DTF) Printing

What is DTF printing? DTF prints a design onto a special film, applies adhesive powder, and then heat-presses it onto the garment.

Best applications:

- Multi-color designs

- Cotton, polyester, blends

- Small to medium production runs

- Print-on-demand and e-commerce

Pros:

- Works on almost any fabric

- High color vibrancy

- More durable than DTG

- No fabric color limitation

Cons:

- Requires specialized equipment

- Adhesives are less eco-friendly

- Print feel is thicker than DTG

=> Notes: DTF is powerful—but bad powder or poor heat pressing leads to cracking. Supplier skill matters.

Heat Transfer Printing

What is heat transfer printing? – This method transfers printed designs from special paper onto fabric using heat and pressure.

Best applications:

- Short-run custom shirts

- Photo prints

- Event or novelty items

Pros:

- High-resolution prints

- Low setup cost

- Fast turnaround

Cons:

- Lower durability

- Can peel or crack

- Heavier feel on fabric

=> Notes: Heat transfer is fine for gifts—not for serious brands selling long-term products.

Dye Sublimation Printing

What is sublimation printing? – Sublimation turns solid dye into gas, bonding it directly into polyester fibers.

Best applications:

- Sportswear

- All-over prints

- Performance apparel

Pros:

- Extremely durable

- No cracking or peeling

- Breathable and lightweight

- Perfect for full-coverage designs

Cons:

- Polyester only

- Light colors required

- Higher setup cost

=> Notes: Trying to sublimate cotton never works. If a factory says it does—they’re lying.

Puff Printing (Special Effect)

What is puff printing? – Puff printing is not a standalone method. It’s a screen-printing effect where ink expands under heat, creating a raised texture.

Best applications:

- Streetwear

- Bold logos

- Limited edition drops

Pros:

- Strong visual impact

- Durable texture

- Premium look

Cons:

- Limited design detail

- Requires skilled curing

- Not suitable for thin fabrics

Heat Transfer Vinyl (HTV)

What is HTV printing? – HTV cuts shapes from vinyl sheets and heat-presses them onto garments.

Best applications:

- Names and numbers

- Small custom orders

- Personalization

Pros:

- Durable

- Wide color and finish options

Cons:

- Not breathable

- Poor for complex artwork

- Not scalable for brands

Embroidery

What is embroidery? – Embroidery stitches designs directly into fabric using thread.

Best applications:

- Corporate wear

- Uniforms

- Premium branding

Pros:

- Extremely durable

- Professional appearance

- High perceived value

Cons:

- Expensive

- Limited detail

- Can distort lightweight fabrics

Conclusion / Final Words

There is no single “best” t-shirt printing method only the right method for your purpose. Screen printing works best for bulk and durability, DTG suits small runs with detailed designs, DTF offers flexibility across fabrics, sublimation is ideal for polyester sportswear, and embroidery delivers a premium, long-lasting look. Most importantly, print quality depends as much on factory skill and process control as the method itself. Always test samples before full production. The right printing choice protects your product quality, your costs, and your brand reputation.