Puff Printing for T-Shirts: Pros, Cons, Benefits and Guide for Brand Owners

If you’re building a clothing brand and exploring printing techniques, you’ve probably heard about puff printing, that raised, 3D look that makes designs pop. But before you commit to it for your next collection, you need to know both the real benefits and the hidden limitations. This article breaks everything down clearly so you can decide whether puff printing fits your brand, your designs, and your customers.

=> Read More: T Shirts Manufacturing Vietnam | Mekong Garment Factory

T-Shirt Printing Methods Comparison:

- Screen Printing for T-Shirts: What It Is, Pros, Cons, Costs, and When to Use It

- Direct-to-Garment (DTG) Printing for T-Shirts: Pros, Cons, and What Brands Must Know

- Direct-to-Film (DTF) Printing for T-Shirts: Pros, Cons

- What Is Heat Transfer Printing for T-Shirts: Pros, Cons, Benefits,…

- Sublimation Printing for T-Shirts: Pros, Cons and Guide for Brand Owners

- Puff Printing for T-Shirts: Pros, Cons, Benefits and Guide for Brand Owners

- Heat Transfer Vinyl (HTV) Printing: Pros, Cons and Benefits

- What Is Embroidery for T-Shirts? A Brand Owner’s Guide

What Is Puff Printing?

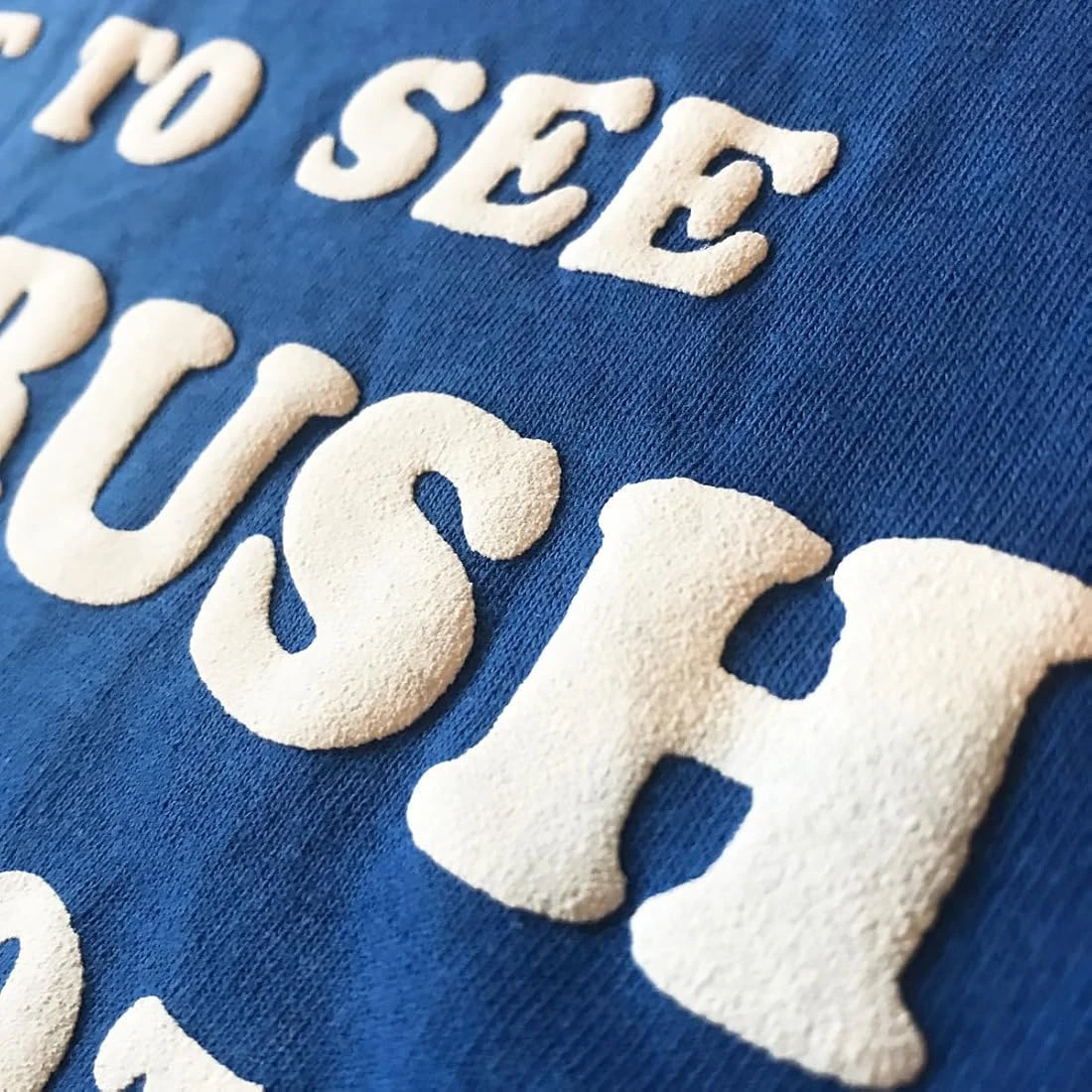

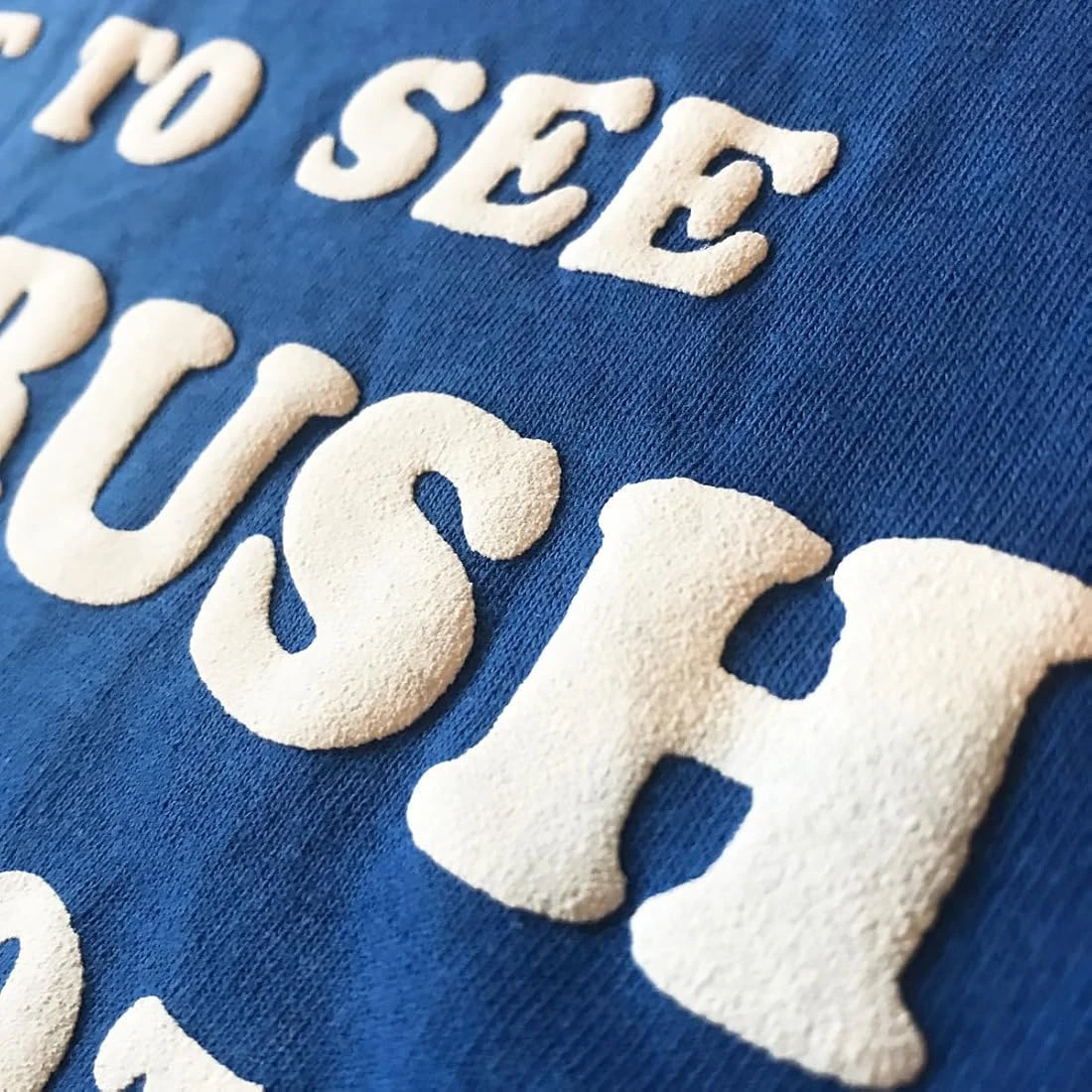

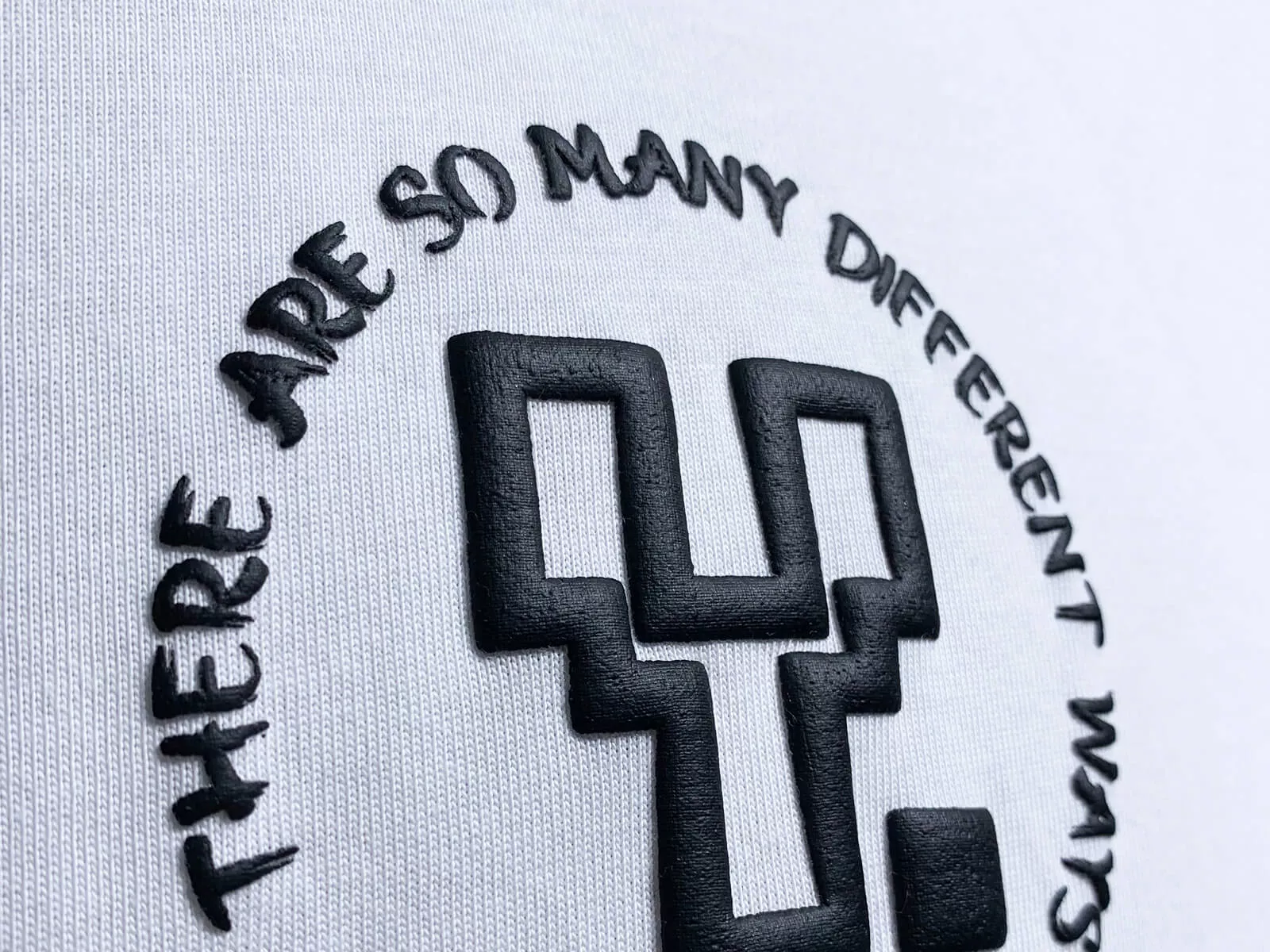

Puff printing is a screen printing variation that uses a special additive mixed into plastisol ink. When heat is applied during curing, the additive expands making the printed area rise above the fabric. Instead of flat ink, your design gets a raised, tactile texture you can feel with your fingertips. In short: puff = texture + depth.

How Puff Printing Works:

Here’s the real process step by step:

- Design Preparation: Simple, bold artwork works best. Tiny details are a problem.

- Ink + Puff Additive: The additive is mixed into the ink before printing.

- Screen Printing: Your design is printed onto the shirt exactly like regular screen printing.

- Curing with Heat: Heat activates the puff additive. That’s when the magic happens: the ink rises.

- Expansion Happens: The design turns 3D, but only if temperature and timing are right.

=> Pro tip: Puff printing isn’t just “screen printing with foam.” It requires precise heat control so the puff rises evenly. This is where less experienced printers often slip up.

When Puff Printing Works — and When It Doesn’t

Here’s the real question every brand owner should ask: Does puff printing add value to my brand message — or just make a design “look cool”?

Best Use Cases:

- Bold brand logos

- Block text or typography

- Accent elements (small parts of the design, not full shirts)

- Limited editions or drop collections

- Streetwear, urban, and youthful fashion

When Puff Might Hurt Your Product:

- Full-shirt intricate designs

- Soft, premium silhouettes

- Brands that pride themselves on minimalism

- Kids’ tees where comfort matters most

Pros and Cons of Puff Printing

Puff printing looks simple on paper: mix a puff additive into ink, apply heat, and the graphic rises into a 3D texture. But for brand owners, the real question isn’t “does it look cool?” it’s whether it holds up in production, fits your design style, and matches your customer’s expectations. Puff can make logos and typography feel more premium and collectible, yet it can also blur fine details, shift color slightly, and create consistency issues if the curing process isn’t tightly controlled. Before you commit it to a full drop, it’s worth weighing the pros and cons with a manufacturing mindset not a trend mindset.

Pros:

Puff printing sounds appealing and it can be but let’s look at what really makes it valuable for a brand:

- 1. Strong Visual Impact: Puff instantly draws attention. Raised prints stand out more than flat prints, which helps your brand visuals pop. But be careful: overusing puff on lots of elements can make designs feel cluttered, not dynamic.

- 2. Tactile Texture That Feels Premium: Texture can make a simple T-shirt feel more expensive without embroidery. However, if the puff layer is too thick, it can feel stiff or uncomfortable — especially on larger graphics.

- 3. Great for Bold Graphics and Logos: Large, solid shapes like block type and bold logos are perfect for puff. Your brand name or emblem can literally stand out on the garment. Small lines and fine detail? Puff will struggle, turning them blurry or uneven.

- 4. Works Well with Streetwear and Casual Fashion: If your brand leans toward trendy, bold looks, puff fits right in. But if your brand’s vibe is premium minimalism, puff may feel too loud or gimmicky.

Cons:

Here’s where most puff guides stop — but we’re not doing that. Brand owners need to understand risks before they invest.

- 1. Not Good for Detailed Designs: Puff requires bold shapes. Thin lines, ghosted shading, and detailed art just don’t puff cleanly. If your brand uses delicate artwork, another printing method might perform better.

- 2. Color Shifts Can Happen: The puff additive can slightly alter how colors look once printed and cured. This matters if your brand uses specific color codes.

- 3. Texture Comfort: Raised prints can feel thicker and bulkier than flat prints. Some customers don’t like that. Always request feel samples before production.

- 4. Higher Cost: Puff ink and the extra curing control needed mean higher cost per shirt than basic screen printing. If you’re pricing products for mass market instead of premium streetwear, the margin impact matters.

- 5. Requires Skilled Printers: Puff printing isn’t forgiving. Inconsistent heat, screen errors, or wrong screens can ruin the 3D effect. That means you need a production partner with experience — not just a regular screen printer.

Puff Printing vs Other Printing Options

Choosing puff printing isn’t really about picking the “best” method it’s about picking the right tool for your design, fabric, order size, and brand positioning. Puff gives you a raised, tactile look that flat prints can’t match, but that texture comes with trade-offs: it favors bold artwork, needs tighter heat control, and can cost more per unit. Meanwhile, methods like classic screen printing, DTF, and DTG each win in different situations whether you need sharp detail, fast scaling, lower cost, or a softer feel. This comparison will help you avoid the common mistake brand owners make: choosing a print method for the effect, then discovering it doesn’t fit the product plan.

| Technique | Texture | Best For | Cost | Detail |

|---|---|---|---|---|

| Puff Printing | 3D raised | Bold graphics & logos | Higher | Low |

| Flat Screen | Flat | Classic prints | Lower | Medium |

| DTG (Direct-to-Garment) | Smooth | Complex art/photos | Higher | High |

| Heat Transfer | Smooth | Small runs | Medium | Medium |

Tips for Brand Owners Before You Produce

If you decide to use puff printing, here’s how to avoid common mistakes:

- Request physical samples first — don’t work from pictures alone.

- Test multiple heat profiles — puff reacts differently on different fabrics.

- Keep designs bold and simple — fine detail rarely works.

- Think strategically — use puff as accent rather than full coverage.

- Get your printer aligned on expectations — temperature, mesh counts, test prints.

Final Thought: A Reality Check

Puff printing can boost the appeal of your T-shirts — but only when used right. It’s easy to choose because it “looks cool,” but the real measure is whether it supports your brand story and product quality. Ask yourself: “Does this technique make my product more valuable — or just more textured?” Because if it doesn’t add value, it adds cost and risk instead.