Garment makers should understand knit fabric shrinkage so you can prevent costly sizing changes; this guide explains causes heat, moisture, agitation, fibre type and construction and practical controls: select stable fabrics, pre-treat or pre-wash, regulate compacting machine temperature, humidity and speed, maintain equipment, and consider approved shrink-control chemicals. You’ll also learn how to measure length and width shrinkage and apply finishing steps that stabilise your garments for consistent quality.

What is Knit fabric Shrinkage

“Knit fabric shrinkage” refers to the reduction in dimensions (length and/or width) of a knitted fabric when it is washed, dried or exposed to heat/ moisture. Because knitted fabrics are made of loops of yarn, the fibres can move, compress or interlock further when moisture and heat are applied, producing shrinkage.

The amount of shrinkage depends on:

- Fibre type (natural fibres like cotton, wool shrink more than synthetics)

- Fabric construction (knits tend to shrink more than wovens)

- Quality/ finishing of the fabric (untreated or low quality fabrics may shrink more)

- Care conditions (washing temperature, drying method, agitation)

You encounter knit fabric shrinkage when the looped structure reduces in length or width after wetting, heating or mechanical action; typical raw shrinkage ranges about 3–6% for cotton knits and 0.5–2% for polyester blends. In practice you measure length-wise and width-wise changes separately (e.g., 100 cm piece → 96 cm equals 4% shrinkage) to set tolerances for production and finishing.

Common Natural Fiber Fabrics & Their Shrinkage:

Natural fibres differ greatly in how they respond to washing, heat, and moisture. Their structure, cellulose content, and surface finish determine how much they shrink after production or laundering. The table below lists the typical shrinkage ranges for common natural fibre fabrics, helping you choose the right material and set realistic tolerance limits in garment production and finishing.

| Fiber Type | Typical Shrinkage Range |

|---|---|

| Cotton | 3–7% |

| Linen | 4–10% |

| Wool | 5–10% |

| Silk | 2–5% |

| Hemp | 3–5% |

| Bamboo (Viscose) | 4–6% |

| Ramie | 3–7% |

| Jute | 3–8% |

| Rayon (Viscose) | 5–8% |

| Lyocell (Tencel) | 2–3% |

| Kapok | 3–6% |

| Piña (Pineapple Fiber) | 2–5% |

| Banana Fiber | 3–6% |

| Coir (Coconut Fiber) | 4–8% |

| Nettle Fiber | 3–7% |

| Kenaf | 3–7% |

| Abaca | 4–9% |

| Milkweed Fiber | 2–6% |

| Lotus Fiber | 2–5% |

| Sisal | 4–10% |

What Causes of Shrinkage?

Knit fabrics often change size after washing or finishing because their looped structure allows yarns to move when exposed to heat, moisture, or mechanical stress. The degree of shrinkage depends on several key factors, including fibre type, fabric construction, and the finishing process.

The table below summarises the main causes of knit fabric shrinkage, showing how each factor affects dimensional stability, the typical shrinkage range, and the best ways to control or prevent it during production and garment care. The article identifies several main causes:

- Heat: Washing, drying or ironing with high heat causes fibres to compress and loops to pull in.

- Moisture: Wetting causes fibres to swell and then when they dry they may pull together.

- Agitation: Movement/rubbing in washing/drying can cause loops to interlock more tightly, reducing size.

- Fibre type: Natural fibres like cotton and wool are more prone.

- Fabric construction: Knits are more likely to shrink than woven fabrics because of their looped structure.

- Fabric quality/finishing: Lower quality fabrics may have less stabilisation and hence more shrinkage.

| Factor | Description | Typical Shrinkage Range | Control / Prevention Tips |

|---|---|---|---|

| Effect of Heat | High washing, drying, or ironing temperatures make fibres relax and loops draw in. Washing above 60°C or tumble-drying on high (~70°C) can add 2–6% extra shrinkage; ironing cotton near 200°C locks in dimensional change. | +2–6% from heat alone | Wash below 40°C, tumble-dry low or air-dry, and iron at moderate temperatures. |

| Role of Moisture | Water causes fibres to swell and loops to pull together when dried, leading to relaxation shrinkage. Cotton has 8–10% moisture regain, wool 13–18%, polyester 0.4%, so higher-regain fibres shrink more. | 2–5% relaxation shrinkage | Pre-wash or wet-relax fabrics before garment assembly; use controlled drying. |

| Impact of Agitation | Mechanical motion in washing/tumbling tightens loops and increases shrinkage. A normal cycle can double shrinkage vs. gentle wash. Wool felting can reach 5–30%; cotton knits add 1–4%. | 1–4% (cotton); up to 30% (wool) | Use gentle cycles, low spin speed, and minimal tumbling to reduce stress. |

| Fiber Type Considerations | Natural fibres shrink more: cotton 2–5%, wool 5–20%, viscose 4–8%, polyester <1%. Mercerised or compacted cotton shrinks less; high-twist yarns improve stability. | Cotton 2–5%, Wool 5–20%, Viscose 4–8%, Polyester <1% | Choose fibre blends with synthetics or use mercerised/compacted yarns. |

| Differences in Fabric Construction | Loop geometry, density, and knit type determine shrinkage. Single jersey shrinks 3–8% in width; interlock 1–3%. Finer gauge and higher stitch density reduce loop mobility. | Single jersey 3–8%, Interlock 1–3% | Prefer tighter constructions like interlock or compact knits for dimensional stability. |

| Quality and Finishing of the Fabric | Poorly finished knits can exceed 5% shrinkage. Sanforising, compacting, or resin cross-linking can reduce to 1–3%. Finishing conditions (temp, moisture, tension) must be well-controlled. | 1–5% depending on process | Apply controlled compacting/sanforising and monitor finishing parameters. |

How To Control Shrinkage (especially in compacting machines for knit fabrics)

The article focuses particularly on controlling shrinkage at the fabric stage in a compacting machine. Key measures include:

- Fabric selection Choose fabrics with appropriate construction, weight and fibre that are less prone to shrinkage. (E.g., a stable knit structure, adequate density etc.)

- Proper pre-treatment Pre-washing or pre-treating the fabric before compacting to remove residual stresses and allow initial shrinkage to occur, stabilising the fabric.

- Control temperature & humidity During compacting, maintain consistent and appropriate machine temperature and ambient humidity so that the fabric is stabilised and doesn’t shrink unpredictably later.

- Control speed The speed at which the fabric moves through the compacting machine affects how much tension or relaxation the loops get controlling speed helps reduce unwanted shrinkage.

- Regular maintenance Ensuring the compacting machine operates as designed and that mechanical issues (rollers, tension devices, feeders) don’t introduce uncontrolled stresses that lead to shrinkage.

- Use of chemicals In some cases, specific chemicals (e.g., stabilisers or shrink-control agents) can be used during the compacting process to reduce subsequent shrinkage. It’s important to follow manufacturer recommendations for type and concentration.

Types of shrinkage & How to calculate

Types of Shrinkage:

Two types: length-wise shrinkage (in the fabric’s length direction) and width-wise shrinkage (in the cross-direction) can both occur.

| Length-wise shrinkage | Reduction along the wale/course direction; shortens body and sleeve lengths |

| Width-wise shrinkage | Reduction across the fabric; narrows chest, hem and overall fit |

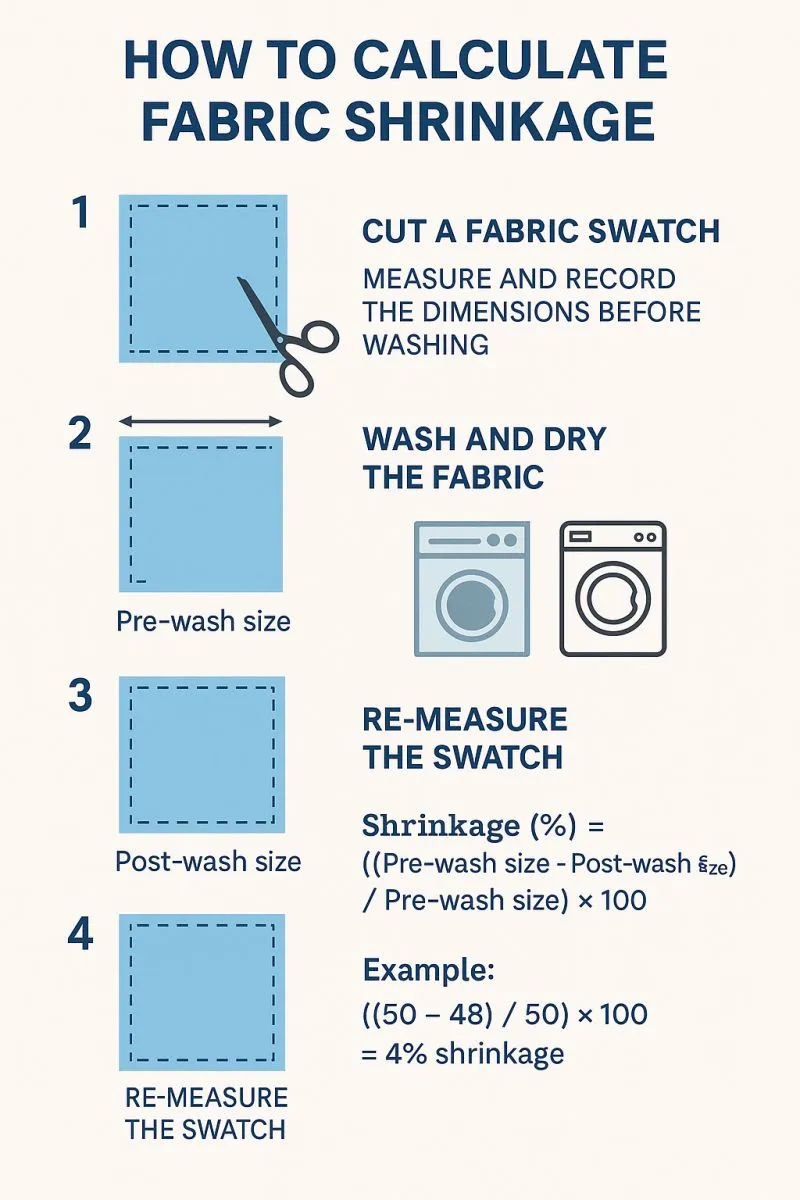

Methods for Calculating Fabric Shrinkage:

To measure fabric shrinkage accurately, several international testing standards are widely used in the textile industry:

- AATCC Test Method 135

- AATCC Test Method 150

- ISO 6330

- CAN/CGSB 58

Each of these methods involves washing and drying fabric samples through controlled cycles, then measuring the fabric’s dimensions before and after the process. By comparing these measurements, the shrinkage percentage is calculated.

In general, a shrinkage rate of 2–3% or less is considered acceptable for most garments and home textiles. However, when shrinkage exceeds 3%, noticeable size and fit changes can occur, often leading to consumer dissatisfaction.

The shrinkage percentage is calculated as Example given: before = 35 cm, after = 33 cm → shrinkage = (33−35)/35×100=−5.7%(33-35)/35 × 100 = -5.7\%(33−35)/35×100= −5.7% (note the negative sign indicates reduction). The shrinkage is less than 5% in many good cases.

Finishing Tips to Minimize Shrinkage

Apply mechanical stabilisation and chemical finishes targeted to your fabric: compact/sanforise cotton knits to target residual shrinkage of 1–3%, heat-set polyester blends at controlled dwell times to lock loop geometry, and use low‑add-on resin finishes or PFC‑free stabilisers to reduce relaxation during laundering. Balance tentering width and overfeed (typically 0–5% overfeed for stable jerseys) and finish with controlled steaming and tension‑free winding to avoid reintroducing stresses.

- Compacting/sanforizing: aim for 1–3% residual shrinkage on cotton jerseys.

- Resin cross linking: low add‑on, cure 150–160°C for short dwell times on cotton blends.

- Heat‑setting: 180–200°C for polyester-blends with short dwell to stabilise loops.

- Tentering/relaxation drying: minimal overfeed, control width to ±1% tolerance.

- Stitch‑setting and steaming: set seams and collars after sewing to prevent garment distortion.

Summing Up / Final Word

From above, you should manage knit shrinkage by selecting stable fabrics, pre‑treating or pre‑washing, and controlling compacting temperature, humidity and speed; maintain equipment and, when appropriate, apply approved shrink‑control chemicals. Monitor length and width shrinkage with simple before/after measurements and aim for under 5% in finished goods. Following these steps ensures predictable results and protects your product quality.

FAQs About How to Control Knit Fabric Shrinkage

What is knit-fabric shrinkage and why does it happen?

Knit-fabric shrinkage is the reduction in a knitted fabric’s length and/or width after exposure to washing, drying, heat or moisture. Knits are made of interlooped yarns, so fibres and loops can move, swell, compress or interlock further when wet or heated. The degree of shrinkage depends on fibre type (natural fibres like cotton and wool shrink more than synthetics), fabric construction (looser knits shrink more), fabric quality and finishing, and the care conditions applied.

What are the main causes of shrinkage in knit fabrics?

The primary causes are heat (high washing, drying or ironing temperatures compress fibres and draw loops tighter), moisture (wetting causes swelling and subsequent contraction on drying), mechanical agitation (washing or tumbling causes loops to interlock more tightly), fibre type (natural fibres are more prone), fabric construction (knits vs. wovens), and inadequate finishing or stabilization during manufacturing.

How do you measure and calculate knit-fabric shrinkage?

Measure dimensions (length and width) before and after the treatment. Shrinkage percentage = (after − before) / before × 100. Example: before = 35 cm, after = 33 cm → (33 − 35) / 35 × 100 = −5.7% (negative sign indicates reduction). Measure both length-wise and width-wise shrinkage; for quality control, many manufacturers aim for shrinkage under about 5% in well-processed fabrics.

What steps control shrinkage during compacting of knit fabrics at the fabric stage?

Key measures: select stable fabric constructions and appropriate fibre blends; perform pre-washing or pre-treatment to remove residual stresses and allow initial relaxation; maintain controlled machine temperature and ambient humidity so the fabric stabilizes predictably; set and monitor fabric feed speed and tension to avoid introducing unwanted stretch or relaxation; perform regular maintenance on rollers, tension devices and feeders to prevent mechanical variability; and, where applicable, use approved shrink-control chemicals per supplier guidelines.

Which finishing treatments and chemicals help reduce knit shrinkage and how should they be applied?

Mechanical finishing such as compaction, controlled heat-setting (for thermoplastic fibres), steaming and controlled drying can stabilize loops and reduce shrinkage. Chemical options include stabilisers and shrink-control agents formulated for knit applications. Apply chemicals at recommended types and concentrations, conduct lab trials on representative samples, and verify results after washing cycles. Avoid over-treatment that can alter hand, breathability or appearance.

What quality checks should manufacturers perform to ensure acceptable shrinkage levels?

Implement incoming fabric evaluation and pre-treatment shrinkage tests, measure length and width before and after prescribed wash/dry cycles, set acceptance criteria (commonly <5% for many finished knits), document compacting machine settings (temperature, speed, tension, humidity) and chemical treatments, conduct routine sampling and statistical monitoring, and carry out corrective actions (adjust compacting parameters, change chemical recipe or fabric selection) when samples exceed limits.