Hook and Eye Fastener: History, Modern Uses, and Why It Still Matters in Garment Design

The hook and eye fastener may seem like a tiny, insignificant part of a garment, but it has played a vital role in fashion history and modern design. This simple two-piece closure a curved hook and a looped eye has held together everything from royal corsets to everyday workwear for centuries. Despite the rise of zippers, snaps, and Velcro, the hook and eye remains a quiet hero in tailoring, lingerie, and high-end fashion. Its strength, subtlety, and reliability continue to make it a favorite among designers who value both precision and elegance. In this article, we’ll explore its origins, modern applications, benefits, and why this timeless fastener still matters in today’s garment industry.

What Hook and Eye Fastener?

A hook and eye fastener is a simple yet powerful garment closure made up of two parts a hook (a bent piece of metal or wire) and an eye (a loop or bar that the hook catches onto). This small device may look ordinary, but it’s an essential component of clothing design, helping garments stay fitted, secure, and elegant without adding bulk. From corsets to couture, this tiny fastener has held garments and style together for centuries.

A Brief History

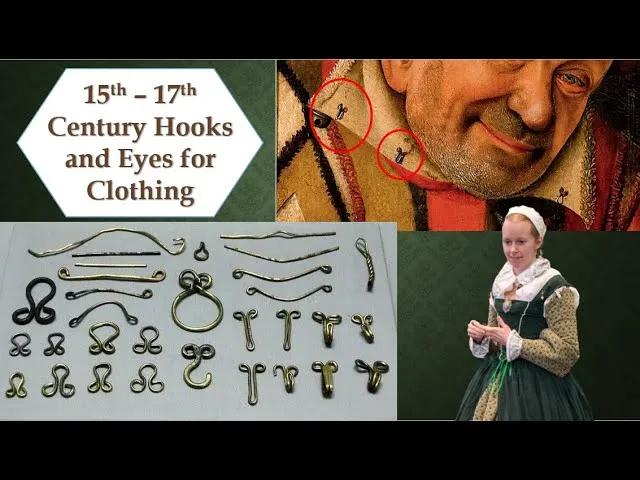

The origins of the hook-and-eye trace back centuries, showing up in early European garments and evolving alongside tailoring techniques. As personal dress shifted from draped fabrics to fitted tailoring, this fastener became a tool for both form and function. With industrialization came mass production, standard sizing, and broader availability. Understanding its history helps us appreciate why it’s still used today. The history of hook and eye fasteners stretches back over 600 years.

- 14th Century: Early forms appeared in medieval Europe, known as “crochets and loops,” handmade from bent wire or twisted metal.

- 16th–18th Centuries: Tailors used them in corsets, waistcoats, and dresses to create a smooth, fitted look.

- 19th Century Industrial Era: Factories in England and the U.S. began mass-producing hooks and eyes, leading to uniform sizing and stronger materials.

- Modern Innovations: In 1889, a U.S. patent introduced a hump-shaped hook design to prevent accidental unfastening a concept still used today.

Despite technological advances like zippers and Velcro, the hook and eye remains timeless due to its simplicity, durability, and discreet design.

How Does a Hook and Eye Fastener Work?

At its core, the mechanism is simple: the hook catches the eye, the tension of the fabric holds it closed, and the assembly prevents unwanted gaps or slippage. Because of this simplicity, it’s reliable, low-bulk, and low-maintenance compared to more complex closures. Its effectiveness depends on material choice, alignment, and how well it’s sewn into the garment. Getting this right helps ensure both function and longevity in final products. It operates on a simple principle:

- The hook catches and locks into the eye, creating tension that holds fabric edges together.

- Once hooked, the tension in the garment keeps it closed until deliberately released.

- When placed correctly, it prevents gaps, secures seams, and supports other fasteners like zippers or buttons.

This tiny component may take only seconds to attach but plays a major role in both comfort and garment structure.

Traditional Uses of Hook and Eye Fasteners

For much of fashion history, the hook-and-eye was integral to garments that demanded precision fit and secure closure think corsets, bodices, tailored waistcoats, and uniform garments. Before zippers became common, it was among the go-to closures for both men’s and women’s wear. Its discreet profile allowed for elegant finishes without visible hardware disrupting the line of a garment. Reviewing its traditional applications gives perspective on how it contributed to both structure and aesthetics in classic dressmaking. Before zippers existed, hooks and eyes were the primary closure system in garments. They appeared in:

- Corsets and bodices for shaping and support

- Men’s waistcoats and trousers for formal dressing

- Women’s skirts and dresses for secure fit

- Military uniforms for polished, structured appearances

In vintage garments, hooks and eyes symbolized precision tailoring and elegance — values still celebrated in high-end fashion today.

Modern Applications in Today’s Fashion and Accessories

Even in an era of fast fashion, 3D-printing, and smart textiles, the hook-and-eye remains relevant—especially in lingerie, tailored eveningwear, adjustable garments, and even sports or industrial gear. In bras and shapewear, it offers fine adjustability; in couture dresses, it gives invisible closure for clean lines; in accessories or outerwear, it can provide discrete, strong fastening. The versatility across sectors means it continues to be specified by designers, manufacturers and brands. Understanding how it fits into modern workflows helps you integrate it effectively in today’s supply chain.

- Lingerie and Undergarments: Hook and eye strips are essential in bras, corsets, and shapewear. They allow size adjustability, strong hold, and comfort customization. Multiple rows of hooks help users fine-tune the fit as fabric stretches with use.

- Designer Dresses and Couture: High-end designers use concealed hooks to ensure clean closure lines at zippers or necklines. They maintain garment shape and prevent unwanted gaps subtle but crucial details that define couture quality.

- Sportswear and Accessories: In athletic wear, lightweight hook fasteners are used where flexibility, durability, and minimal weight are key such as removable straps or waist adjustments.

- Industrial and Safety Gear: Heavy-duty versions secure work uniforms, protective suits, or fire-resistant clothing.

These are made from stainless steel or brass, offering high strength and corrosion resistance.

Types of Hook and Eye Fasteners

Over time, designers and manufacturers developed various versions of the hook-and-eye to meet different needs of fit, aesthetics, strength, and ease of production. From the classic sew-on style to concealed finishes, tape-mounted strips, and hybrid snap versions, each type solves specific design challenges. Choosing the right type means balancing bulk, adjustability, production speed, and visual impact. In modern factories, understanding this typology helps streamline sourcing and manufacturing decisions.

Sew-On Hook and Eye

The classic type found in tailoring and lingerie. Each hook and eye is sewn individually onto fabric using a needle and thread. Best for: Waistbands, skirts, blouses, and dresses where a hidden finish is desired.

Concealed Hook and Eye

Designed to remain invisible from the outside, these are hidden within seams or linings for a smooth look. Best for: Evening gowns, couture dresses, and high-end fashion that demands seamless aesthetics.

Tape Hook and Eye

These come pre-attached to fabric tape, making them quick to sew into garments. They’re common in lingerie, bras, and shapewear where multiple rows allow adjustable fit. Best for: Bras, corsets, and waist trainers.

Snap Hook and Eye

A hybrid between traditional hooks and snaps, offering faster fastening and stronger hold. Best for: Workwear, outerwear, or protective clothing that requires secure closure with easy use.

Pros and Cons of Hook and Eye Fastener

Pros:

The hook-and-eye offers several compelling benefits: minimal bulk, ease of repair, cost-effectiveness, low-profile aesthetic, and reliably secure grip. These strengths make it especially suited for garments where finish, adjustability and discreet closure matter more than high-speed automated fastening. From a factory and compliance viewpoint, simplicity means fewer failure points and easier QC. Recognizing its advantages allows you to deploy it strategically rather than reflexively defaulting to more complex fasteners.

- Durable: Made of metal or coated wire, hooks and eyes withstand years of wear without breaking. They hold firmly even under tension, making them perfect for tight-fitting garments.

- Easy to Repair: If damaged, a single hook or eye can be replaced in minutes — no need to remove seams or re-sew entire sections.

- Minimal Bulk: Their flat, compact design allows garments to close smoothly without visible bumps or added weight.

- Low Cost: Hooks and eyes are inexpensive to produce and easy to attach, saving both materials and labor time in mass manufacturing.

- Reliable Grip: When properly aligned, they provide a secure hold that resists accidental unfastening, ensuring garments stay in place during wear.

Cons:

Despite their many advantages, hook and eye fasteners also have several drawbacks that designers and manufacturers should consider:

- Limited Strength: Not ideal for heavy or high-tension garments; hooks may bend or pull loose under stress.

- Manual Alignment Needed: Requires careful hand coordination to fasten correctly — slower than zippers or Velcro.

- Can Damage Delicate Fabrics: Sharp metal edges may snag or tear thin materials like silk, lace, or chiffon.

- Prone to Corrosion: Metal parts can rust or tarnish over time, especially if exposed to moisture or harsh detergents.

- Minimal Visual Appeal: Usually hidden from view, so they add little to a garment’s aesthetic or design detail.

- Easy to Lose During Repairs: Their small size makes them easy to misplace or drop, especially during sewing or replacement work.

Maintenance Tips for Hook and Eye Fasteners

Ensuring the longevity of hook-and-eye closures requires simple but consistent care: fasten before washing, avoid harsh chemicals, inspect alignment and replacement needs, and choose correct materials for the environment (e.g., humidity, salt-water, frequent laundering). In manufacturing or for export garments, this means specifying appropriate finishes (Corrosion-resistant plating, nylon-coating, etc.) and providing user-care instructions. A small investment in maintenance guidance can reduce customer returns and improve brand reputation. To extend their life and maintain performance:

- Always fasten hooks before washing garments to prevent snagging.

- Avoid bleach or strong detergents that can corrode metal parts.

- Inspect regularly for bent or loose hooks and replace them promptly.

- Hand-wash delicate lingerie with mild soap to protect hook plating.

A little care ensures long-lasting use and keeps garments looking sharp.

Conclusion / Final Words

The hook and eye fastener may be small, but its impact on garment design is undeniable. From medieval corsets to modern lingerie and couture, it remains a symbol of strength, simplicity, and sophistication. Its continued use across industries from fashion to safety gear proves that sometimes, the simplest solutions stand the test of time.