There’s a reason polyethylene fabric is a go-to material: you get a versatile, industrial-grade textile made from ethylene that delivers lightweight yet strong performance, waterproof durability, and cost-efficiency for tarps, covers, bags, and shelters. You should know its limits too-low heat resistance and the material’s non-biodegradable nature can pose safety and environmental concerns-so choose formulations, coatings, and recycling practices that match your application.

What Is Polyethylene Fabric?

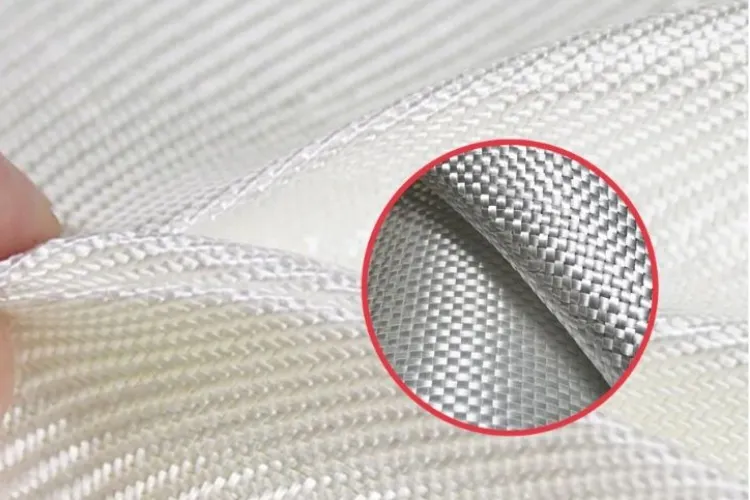

Polyethylene (PE) is one of the world’s most widely used plastics: a thermoplastic polymer made from ethylene units. “PE fabric” refers to textile-like materials made from polyethylene often by extruding polyethylene resin into thin filaments or strips, then weaving or bonding them.

| Density | ~0.91-0.97 g/cm³ (varies by grade) |

| Melting point | LDPE ~105-115°C; HDPE ~125-135°C |

| Crystallinity | Higher in HDPE → greater stiffness and strength |

| Branching | More in LDPE → increased flexibility and elongation |

| Common processing | Extrusion to tapes/films → weaving, lamination, coating |

Types of PE Fabric & How They Differ

PE fabric can be produced as woven fabric, where PE strips are woven like threads, or as laminated / coated structures, often used for heavier-duty or waterproof applications. The performance of PE fabric depends heavily on the underlying form of polyethylene and how the fabric is processed. There are different forms of polyethylene, and correspondingly different types of PE fabric:

- High-Density Polyethylene (HDPE: denser, stronger, more rigid.

- Low-Density Polyethylene (LDPE): softer, more flexible, less dense.

- Linear Low-Density Polyethylene (LLDPE): offers a balance: more durable/flexible than LDPE, often used where toughness + flexibility needed.

- Ultra High Strength (UHMWPE) – fibres, ropes, ballistic uses

- Metallocene PE – improved toughness and uniformity

=> Read More: Pros & Cond of Polyethylene Fabric ( PE Fabric )

| Woven PE Fabric | Interlaced PE strips offering high tensile strength, common in sacks, FIBCs, and tarps; low cost and good tear resistance. |

| Laminated and Coated PE Fabric | Base PE fabric laminated or coated with LDPE/PU/PVC films to add waterproofing, UV and chemical protection, and improved seam sealing. |

| High-Density Polyethylene (HDPE) | Crystalline, stiff polymer used for geotextiles, heavy-duty tarps and liners; provides very high strength-to-weight and excellent chemical resistance. |

| Low-Density Polyethylene (LDPE) | More flexible and soft, used where flexibility and impact resistance matter-liners, sheeting, and light covers; lower melting point than HDPE. |

| Linear Low-Density Polyethylene (LLDPE) | Combines strength and flexibility with improved tear resistance vs LDPE; common in blow films, flexible tarps, and welded laminated products. |

Why It’s Valuable: The Properties of PE Fabric

Garment grade polyethylene fabric is a lightweight, cost-effective material you can use when you need durable, waterproof protection for tarps, covers, packaging, or shelters; you’ll value its chemical and UV resistance and high strength to weight ratio, but be aware of its poor heat resistance and non-biodegradable nature, which limit high-temperature use and long-term environmental disposal. PE fabric stands out because of the combination of physical and chemical properties inherited from polyethylene:

- Lightweight yet strong PE has a high strength-to-weight ratio, especially HDPE-based fabric, which provides tensile strength without heavy bulk.

- Waterproof / Water-resistant PE’s hydrophobic nature makes fabrics made from it resistant to water, moisture, and damp conditions; ideal for tarps, covers, outdoor use.

- Durable and Tear-Resistant Resistant to tearing, puncturing, and abrasion; holds up under rough handling.

- Chemical, Moisture, and Weather Resistance PE resists many chemicals, and PE fabrics (especially treated or coated) can resist UV, mildew, and weather exposure.

- Flexibility & Ease of Processing Depending on formulation (LDPE, LLDPE), PE fabric can be flexible, easy to handle, cut, sew or laminate.

- Cost-Effective Compared to many synthetic textiles or specialized barriers, PE fabric tends to be relatively inexpensive to produce.

Because of these traits, PE fabric is often the go-to solution when you need durability + water/chemical resistance + low cost especially for functional, industrial, or outdoor uses.

Lightweight and Strong

You’ll notice PE fabric’s high strength-to-weight ratio immediately: HDPE woven sacks and tarpaulins deliver structural tensile support without heavy bulk, so a 150-250 g/m² PE tarp can cover large areas while you still handle it easily. In practice that means bulk bags and FIBC liners can carry hundreds to over a thousand kilograms while remaining simple to lift and transport.

Waterproof and Water-Resistant

Because PE is inherently hydrophobic, your PE sheets and laminated fabrics provide reliable water resistance for tarps, greenhouse covers, and cargo wraps; coated variants form fully waterproof barriers used for pond liners and boat covers. Non-laminated woven PE typically sheds spray and light rain, while laminated PE stops direct water penetration.

For more demanding jobs you can choose LDPE film lamination or PE/PVC coatings to achieve complete waterproofing; manufacturers often pair welded seams or heat-sealed hems to maintain barrier integrity. Be aware that standard woven PE is non-breathable, so you may need venting or breathable layers to prevent trapped condensation in enclosed applications.

Durability and Tear-Resistance

PE fabric stands out for resisting tears, punctures, and abrasion, making it ideal when you need rugged performance; woven HDPE constructions and reinforced hems let your covers and sacks survive rough handling and repeated use. That tear-resistant behavior is why logistics and construction use PE for heavy-duty protection.

More specifically, rip-stop weaving, shoulder-reinforcement, and laminated overlays increase puncture resistance and fatigue life. You’ll extend service life further by adding edge binding, bar-tack reinforcement at load points, or UV-stabilized coatings to reduce mechanical breakdown under cyclic loads.

Chemical and Weather Resistance

PE resists many common chemicals-your fabric will typically tolerate dilute acids, alkalis, and many salts-so it’s a go-to for agricultural covers and chemical sacks. At the same time, prolonged UV exposure can weaken untreated PE, so outdoor-grade products are often stabilized or coated.

In application, you’ll find PE liners used for fertilizer and feed because they resist moisture and corrosive residues; however, aromatic hydrocarbons and strong oxidizers can attack the polymer, so you should choose specialty formulations or internal liners when storing aggressive solvents or high-temperature chemicals.

Flexibility and Ease of Processing

Depending on grade (LDPE, LLDPE vs HDPE), PE fabric can be highly flexible and easy for you to cut, stitch, heat-seal, or weld, simplifying manufacturing and field repairs. That processability makes on-site modifications and custom sizing straightforward.

Practically, you can sew woven PE for strength, then reinforce seams with heat-seal tape or ultrasonic welding to restore waterproofness; heat sealing, hot-air welding, and RF welding are common methods used in factories and by installers to create reliable, repeatable joints.

Cost-Effectiveness

PE fabric’s raw material and production costs are low relative to many coated textiles, so you’ll get a functional product at a fraction of the price of specialty membranes-affordable performance that scales for large-area uses. That economy explains its dominance in packaging, agriculture, and tarpaulins.

On a lifecycle basis, upfront savings combine with longevity (when UV-stabilized) to reduce replacement frequency; additionally, many PE products can be collected and recycled, allowing you to recover material value and lower long-term waste costs compared with single-use alternatives.

Applications of PE Fabric

PE fabric’s versatility means it shows up in many areas. Some of the main uses today:

- Industrial Packaging & Bulk Bags: Heavy-duty PE woven fabric is widely used for making sacks, bulk bags (FIBC), and industrial packaging. Its strength, tear resistance, and water resistance protect goods during storage or transit.

- Tarpaulins, Covers, and Sheeting: From truck canopies, cargo covers, outdoor equipment covers, to temporary roofs or shelters PE tarpaulin fabric is popular for being waterproof, light, and durable.

- Agriculture & Horticulture: Used for greenhouse covers, shade cloths, ground/soil liners, protective covers against weather, dust, and moisture; also for storage bags for seeds, fertilizers, feed, produce.

- Construction & Civil Engineering: As temporary sheeting, ground liners, vapor barriers, protective covers during construction, and even in geotextiles for soil stabilization or landfill liners (especially when more engineered HDPE fabric is used).

- Marine, Logistics, Outdoor Use: Because PE fiber/fabric floats (in some variants), resists water, and doesn’t rot or absorb moisture, it’s used for ropes, nets, boat-covers, tarps good for fishing nets, mooring ropes, floating lines, cargo securing straps.

- Temporary Structures & Shelter Covers: Lightweight PE fabric can serve as the material for tension fabric structures, event tents, protective canopies, or temporary shelters especially where a balance of lightness, weather-resistance, and cost matters.

Why PE Fabric Remains Widely Used Today

Given the combination of properties durability, waterproofing, strength, flexibility, low cost, versatility PE fabric occupies a “sweet spot” for applications demanding functionality over aesthetics.

Industries such as agriculture, logistics, construction, marine, packaging, and outdoor gear rely heavily on PE fabric because it meets practical needs tight in cost, performance, and adaptability. With advances in polymer processing, coatings, composite fabrication, and recycling, PE fabric continues evolving giving improved weather resistance, tailored strength/flexibility balancing, and better lifetime performance. Thus, even as newer synthetic fibers or advanced materials emerge, PE fabric’s mixture of simplicity, robustness, and economy keeps it relevant and often irreplaceable for many real-world tasks.

Safety, Environmental & Sustainability Considerations

Because polyethylene is one of the world’s most-produced plastics, environmental impact is a valid concern. PE and thus PE fabric is not readily biodegradable. That said, some mitigation and responsible uses can help:

- PE fabric’s chemical stability and inertness make it generally safe for many applications, even in agriculture, packaging, or places where contact with people or food occurs, assuming manufacturing uses appropriate standards.

- Some PE-based fabrics (or related materials) are engineered to resist UV, aging, and chemical breakdown extending their usable lifetime, which reduces need for frequent replacement.

- Because PE is recyclable, when collected and processed properly, used PE fabric can be re-processed helping reduce plastic waste compared to single-use plastics.

However, recycling infrastructure and practices remain critical: without proper collection or recycling channels, PE fabric waste may still contribute to long-term environmental burden. Hence for sustainable use it’s best to maximize durability, reuse when possible, and recycle responsibly.

Conclusion / Final Words

“Polyethylene fabric” might not sound glamorous but its strength is in being workhorse material: simple, strong, durable, waterproof, flexible, affordable. From tarpaulins and bulk bags to greenhouse covers, construction sheeting, cargo wraps, and industrial uses PE fabric quietly supports a vast array of everyday and industrial functions.

The trade-offs (heat sensitivity, non-breathability, environmental concerns) limit its use in comfort-centered or high-end textile contexts but for functional, protective, or heavy-duty needs, it remains one of the most practical and cost-effective materials available. As long as proper reuse and recycling practices are followed, and as long as industries value its unique balance of properties, PE fabric will likely remain a cornerstone material in many sectors for years to come.

FAQs About Polyethylene Fabric (PE Fabric)

Inshort, What is polyethylene fabric and how is it manufactured?

Polyethylene fabric is a textile-like material made from polyethylene (PE) resin. Manufacturers extrude PE into thin filaments or strips and then weave them into fabrics or bond/laminate films onto backing layers. Variants include woven PE (common for sacks and tarps) and laminated/coated PE for heavier-duty or waterproof applications; different PE grades (LDPE, LLDPE, HDPE) produce different flexibility and strength profiles.

What key properties make PE fabric valuable for industrial and outdoor uses?

PE fabric combines a high strength-to-weight ratio (especially with HDPE), water resistance due to PE’s hydrophobic nature, good tear and abrasion resistance, and chemical and weather resistance. It is flexible and easy to process (cut, sew, laminate), and generally low-cost compared with many specialized textiles, making it well suited for functional, heavy-duty applications.

How do different types of PE fabric differ in performance?

Performance depends on the polymer grade and processing: HDPE-based fabrics offer higher tensile strength and stiffness; LDPE/LLDPE variants provide more flexibility. Woven PE (strips or tapes woven like threads) is strong and economical, while laminated/coated PE adds waterproofing, UV protection, and durability for harsher environments. Additives and coatings further modify UV stability, chemical resistance, and surface finish.

What are the most common applications for polyethylene fabric?

Typical uses include industrial packaging and bulk bags (FIBC), tarpaulins and cargo covers, greenhouse and agricultural covers, ground liners and vapor barriers in construction, marine gear (boat covers, nets, floating lines), temporary shelters and tents, and ropes or straps. Its balance of durability, water resistance, and cost makes it widespread across agriculture, logistics, construction, and outdoor sectors.

What limitations should users consider when choosing PE fabric?

PE fabric softens or deforms at moderate to high temperatures, has low elasticity and poor stretch recovery, and is generally non-breathable and uncomfortable for clothing. It is not biodegradable, so improper disposal contributes to long-term plastic waste. It also lacks the soft hand-feel, drape, and high-end aesthetic of natural fibers or specialty textiles.