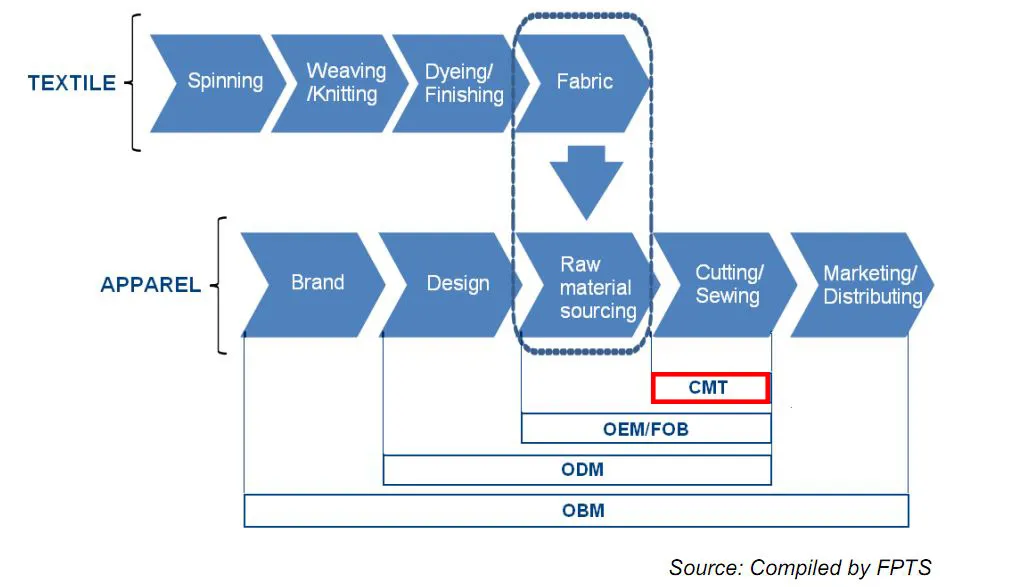

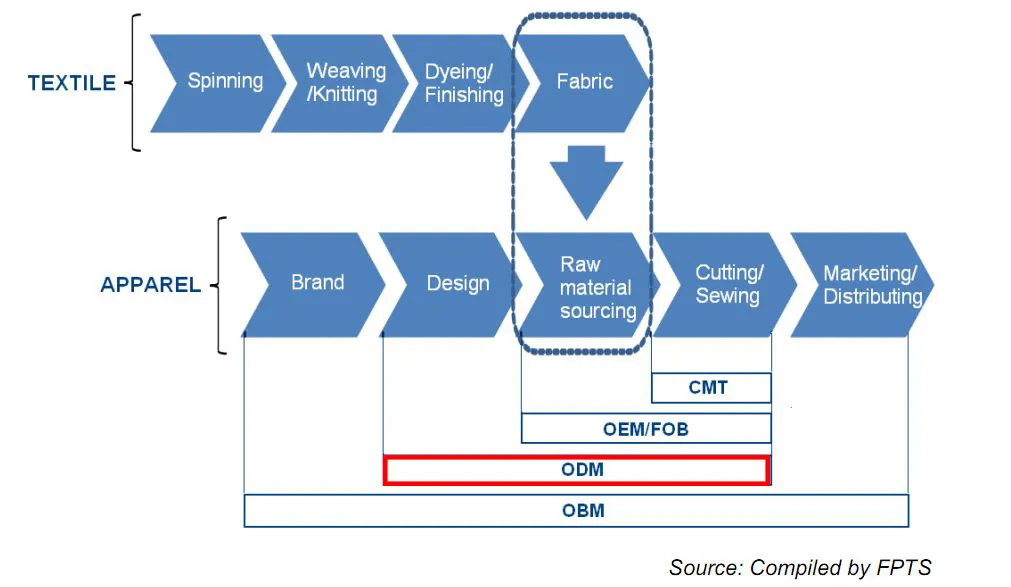

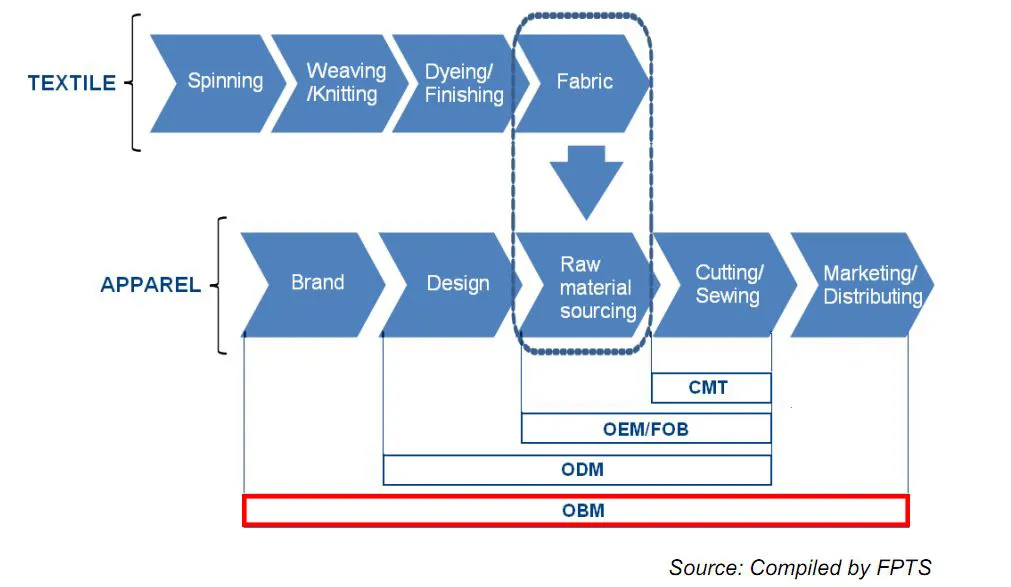

4 Main Production Models in the Garment Industry: CMT, OEM/FOB, ODM, and OBM

The garment industry has many ways to produce clothing, and each method gives factories and buyers a different level of control, cost, and responsibility. Whether you run a small workshop or manage a large manufacturing business, understanding these four production models helps you choose the best fit for your goals. In this article, we will walk through CMT, OEM/FOB, ODM, and OBM in simple, clear language so you can see how each model works and when to use it.

Overview Production Models: CMT, OEM/FOB, ODM, and OBM

- CMT – low capex, buyer supplies fabrics

- OEM/FOB – factory sources materials, higher margin

- ODM – design + production, faster assortment

- OBM – brand ownership, full commercial risk

=> Related Article: What Is CM (Cut & Make) in the Garment Industry?

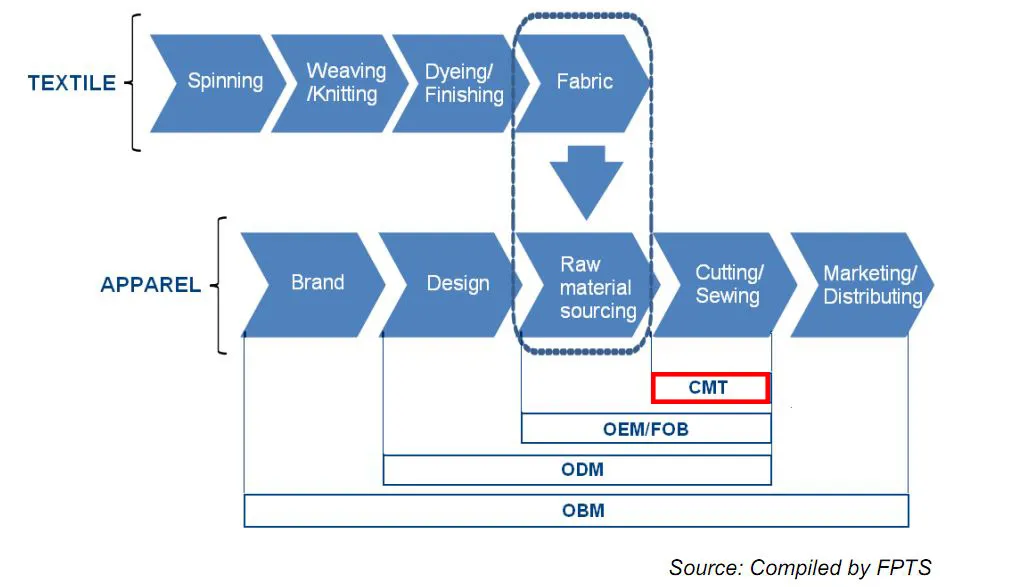

CMT (Cut – Make – Packed – Trim)

You keep design control while the factory handles production steps only, making CMT ideal for brands/buyers that supply fabrics. Typical MOQs range from 500 – 2,000 pieces, lead times sit around 2-6 weeks, and many Vietnam-based CMT shops run 10,000-50,000 garments monthly. This model lets you minimize factory capital investment and focus on sourcing and design, while the manufacturer concentrates on efficient cutting, sewing, and packing to your specifications. You pay a per-piece CMT fee that usually reflects labor intensity-simple tees may be $0.50-$2, while complex garments with linings or embroidery can reach $5-$8 in some markets.

=> Related Article: What Is CMT (Cut, Make, Trim) in the Garment Industry?

How CMPT Works

You send fabric, patterns, labels, and packing instructions; the factory then cuts marker layouts, sews components, attaches trims, performs inline QC, and packs per your specs. Samples can be turned around in 3-7 days, while bulk runs usually take 2-6 weeks depending on complexity and order size. Inspecting incoming materials at your supplier or a third-party lab helps prevent issues since the factory rarely controls fabric quality under CMT.

- The buyer sends fabric, patterns, labels, packing instructions, and QC team.

- The factory cuts, sews, irons, trims threads, and packs the garment.

- The buyer handles all design, sourcing, and materials.

Advantages

CMT gives you low factory investment and operational simplicity-factories face low financial risk, you (buyers) keep material and design control, and the model suits startups or niche brands wanting flexibility and fast sampling without large sourcing overhead. Because the factory doesn’t purchase farbics inventory, overhead stays low and you can iterate designs quickly: many startups launch with 1,000 – 2,000 units via CMT to test markets. You also maintain fabric traceability for sustainability claims and can enforce custom trims and labels directly, which helps with brand consistency while the manufacturer focuses on efficient production flow.

- Very low risk for the factory.

- Easy to operate and requires less capital.

- Suitable for small workshops and new factories.

Limitations

Main drawbacks are low margins for the factory and heavy dependence on you for materials and logistics; quality issues in supplied fabric or trims often cause delays and disputes since the factory rarely controls raw-material quality. Operationally you shoulder sourcing risk and inventory costs, and variations like dye-lot differences or incorrect fabric specs can force reorders or price renegotiation. Factories may add handling fees for complex trimming or extra QC; to mitigate this you should set clear incoming inspection criteria, use third-party labs when needed, and build contingency time into lead schedules.

- Low profit margin.

- Factory depends completely on buyer’s materials.

- Limited control over quality of fabric and trims.

Best For

Choose CMT when you want tight control over fabric/design, run small to medium batches, or test new styles-it’s ideal for boutique labels, private-label lines, and brands sourcing specialty or sustainable textiles who need flexibility and traceability. For example, if you source organic cotton or specialty prints and need precise color or hand-feel control, CMT lets you verify materials before production and launch with 500 – 2,000 piece runs. Avoid CMT when you need the factory to scale sourcing or absorb inventory risk for large-volume, cost-driven lines above ~5,000 units per month.

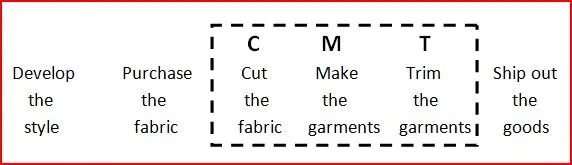

OEM / FOB (Original Equipment Manufacturing / Free On Board)

OEM/FOB means the factory searches local supplies (need approvals from buyers), trims, and accessories, manufactures your garments, then delivers finished goods to the shipping port under FOB terms; you handle freight and customs. Typical MOQs run from 1,000 – 10,000 pieces, sample lead times are ~1-3 weeks, and bulk lead times commonly sit at 6-12 weeks. This model shifts sourcing responsibility and inventory risk to the manufacturer while giving you a simpler, turnkey production service.

=> Related Article: OEM/FOB in the Garment Industry: What It Really Means

How OEM/FOB Works

You provide a tech pack or sample, the factory sources materials and issues lab dips/strike-offs, creates pre-production (PP) samples, proceeds to bulk after approval, performs inline and final QC, packs per spec, and delivers to the agreed port with all shipping documents; you arrange shipping and customs clearance. In practice that workflow includes specific checkpoints: lab dip approval (1-2 rounds), PP sample sign-off, fabric inbound inspection, inline QC every production run, and a final AQL inspection-typically AQL 2.5 for garments. Documents sent at FOB delivery include commercial invoice, packing list, bill of lading, and certificate of origin; payment milestones often follow 30% deposit / 70% at B/L or L/C terms.

- Client gives tech pack or sample.

- Factory searches local supplies for fabric, trims, and accessories.

- Factory makes samples, mass produces, and packs.

- Goods are delivered to the port (FOB).

- Buyer handles shipping and customs.

Advantages

OEM/FOB gives factory higher margins than CMT because the factory controls sourcing and can leverage supplier pricing; you gain convenience since the manufacturer manages procurement, QC, and port delivery. It’s ideal when you want manufacturing scale without running purchasing operations.

- Factory has more control over quality.

- Higher profit margin than CMT.

- Buyers only need to provide ideas or tech packs: fast and convenient.

Limitations

Manufacturers bear sourcing and inventory risk, increasing their capital requirements and exposure to order cancellations or style obsolescence; you must rely on the factory’s QC and traceability systems. Poor vendor control can lead to shipment rejections or delayed exports.

- Factory must invest in sourcing materials.

- Higher financial risk due to inventory.

- Requires strong QC systems.

Best For

Factories that want to grow beyond simple sewing. Buyers who want full manufacturing service without handling all materials.

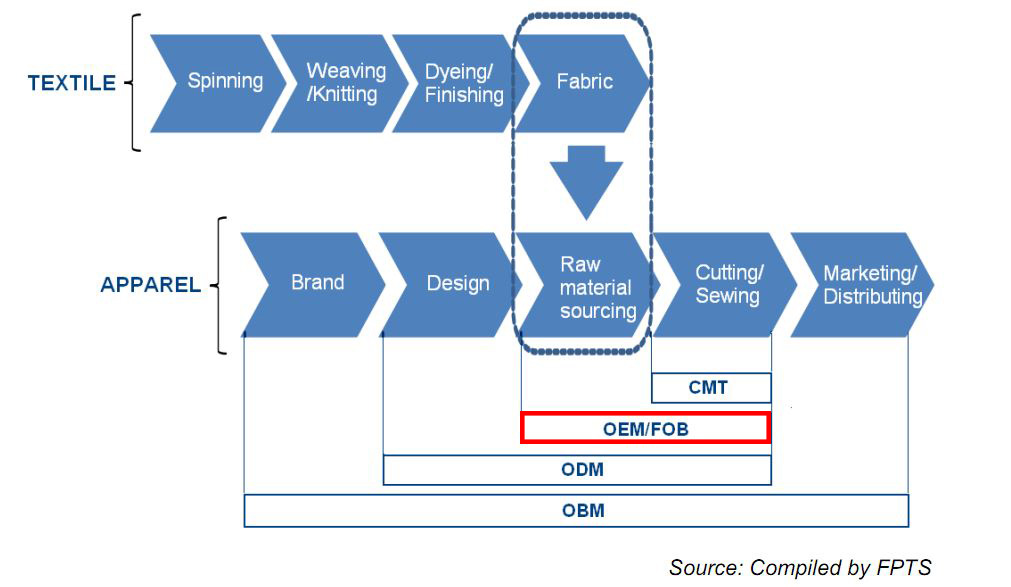

ODM (Original Design Manufacturing)

With ODM you hand over product development: the factory creates designs, patterns, sources materials, and manufactures finished garments so you can scale fast without an in-house design team. Typical ODM orders have MOQs of 1,000-5,000 pieces, sample lead times of 1-14 days, and bulk lead times around 6-12 weeks, making it ideal when you need speed and turnkey solutions.

How ODM Works

You receive factory concepts or choose from full collections; the factory then finalizes tech packs, develops samples, sources fabrics/trims, gains approvals, and moves to mass production and packing. Expect multiple fit iterations and a clear IP/exclusivity agreement before bulk runs to avoid surprises. The workflow usually starts with a design brief or trend sheet, then the factory’s design team (often 2-10 people) produces 3-10 concept samples. You approve fits and colors; the factory sources materials-sometimes from preferred mills in Vietnam, China, or Bangladesh-performs lab tests (shrinkage, colorfastness), runs pre-production samples, and sets up production lines. In practice, a single style can consume $2,000-$30,000 in development costs depending on complexity and fabric choices.

- Factory creates design concepts or full collections.

- Factory prepares patterns, materials, and samples.

- Buyer chooses designs and places orders.

- Factory handles full production and packaging.

Advantages

You gain fast market entry and lower internal design overhead because the factory handles R&D, sourcing, and sampling; that saves you time and can reduce product development cost by up to 30-50% versus building an in-house team for small brands. Beyond cost savings, ODM lets you leverage factory relationships with mills and trim suppliers to access specialty fabrics or bulk pricing that would be hard to source alone. Factories with strong technical teams can also propose margin-improving value engineering (simpler constructions or alternative materials) without reducing perceived quality.

- Very attractive for buyers with small teams.

- Saves time and reduces design costs.

- Factory becomes more competitive and unique.

Limitations

You risk design duplication and loss of exclusivity if contracts aren’t airtight; plus the factory bears high development cost and inventory risk, so pricing and IP clauses must be negotiated carefully to protect your brand and margins. Operationally, quality consistency can vary between production runs unless you set strict QC and approval gates. Additionally, factories often retain pattern blocks and specifications, so without exclusivity you might find your designs appearing elsewhere. Expect to invest in legal agreements and occasional third-party inspections to mitigate these risks.

- High development cost for the factory.

- Risk of design duplication if not exclusive.

- Requires strong R&D, designers, and technical staff.

Best For

Factories with design capability who want to offer more than basic manufacturing. Buyers who need fast product development or lack design resources. ODM fits buyers who lack design capacity-small brands, private labels, and retailers wanting seasonal collections-plus factories aiming to move up the value chain by offering end-to-end services and higher margins per style. Specifically, fast-fashion retailers, boutique brands launching multiple SKUs per season, or overseas buyers entering new categories use ODM to compress development timelines. Factories offering ODM often target export markets (EU, US, Japan) where speed-to-market and consolidated supplier relationships deliver measurable competitive advantage.

OBM (Original Brand Manufacturing)

In OBM you not only manufacture but also own the label, manage packaging, marketing, and sales channels, turning production into a consumer-facing business. You gain full control over brand identity and customer experience, often unlocking significantly higher margins (commonly >30-40% gross) compared with contract manufacturing, but you also accept greater upfront investment and inventory risk as you build distribution and demand.

How OBM Works

- Factory builds its own brand identity.

- Designs products, sources materials, and produces goods.

- Handles marketing, e-commerce, wholesale, and distribution.

- Sells directly to consumers or retail partners.

Advantages

By owning the brand you capture retail markup, control pricing and positioning, and build long‑term business value. You gain direct access to customer data for faster product iteration and can diversify revenue through wholesale, e‑commerce, and private label partnerships. Brand equity becomes an asset that can drive repeat sales and higher lifetime value.

- Highest profit margin for Factory.

- Factory Full control over quality, branding, and customer experience.

- Builds long-term business value.

Limitations

- Very high investment for Factory.

- Requires strong skills in branding, marketing, and logistics.

- Higher overall risk if products do not sell.

Best For

Factories aiming to become fashion brands. Companies with strong capital and long-term vision.

Comparative Analysis of Production Models

| Model | Who Provides Materials? | Who Designs? | Profit Level | Risk Level | Ideal For |

|---|---|---|---|---|---|

| CMT | Buyer Only | Buyer | Low | Very low | Small factories, simple sewing |

| OEM/FOB | Factory / Buyer | Buyer | Medium | Medium | Growing factories; stable orders |

| ODM | Factory Only | Factory | Medium–High | High | Factories with design teams |

| OBM | Factory Only | Factory | Very High | Very High | Brand builders and big investors |

Which Model Should You Choose?

- Choose CMT if: Your factory is small, low-investment, or you want to focus only on sewing.

- Choose OEM/FOB if: You want more control over materials and production, and want higher profit margins.

- Choose ODM if: You have design talent and want to offer full service to clients.

- Choose OBM if: You want to build your own brand and control the whole value chain.

Final Words / Conclusion

Understanding these four production models helps you shape a clear direction for your garment business. Each model has its own benefits and challenges, and the right choice depends on your resources, vision, and long-term strategy. Whether you stay safe with CMT or aim high with OBM, what matters most is building a reliable system, strong quality control, and a sustainable business.