In the garment-manufacturing world, thread codes like 40/2 and 60/3 reflect important structural differences — and choosing the right one affects seam strength, appearance and suitability for different fabrics. Below is a detailed comparison.

| Thread Code | Filament Fineness | # of Filaments | Typical Use | Key Benefit |

|---|---|---|---|---|

| 40/2 | “40” (moderate fineness) | 2 | Standard apparel fabrics | Good balance between thickness and strength |

| 60/3 | “60” (finer filaments) | 3 | Lighter fabrics / finer seams | Finer finish + more filaments = stronger/less bulky seam |

What Do 40/2 and 60/3 Mean?

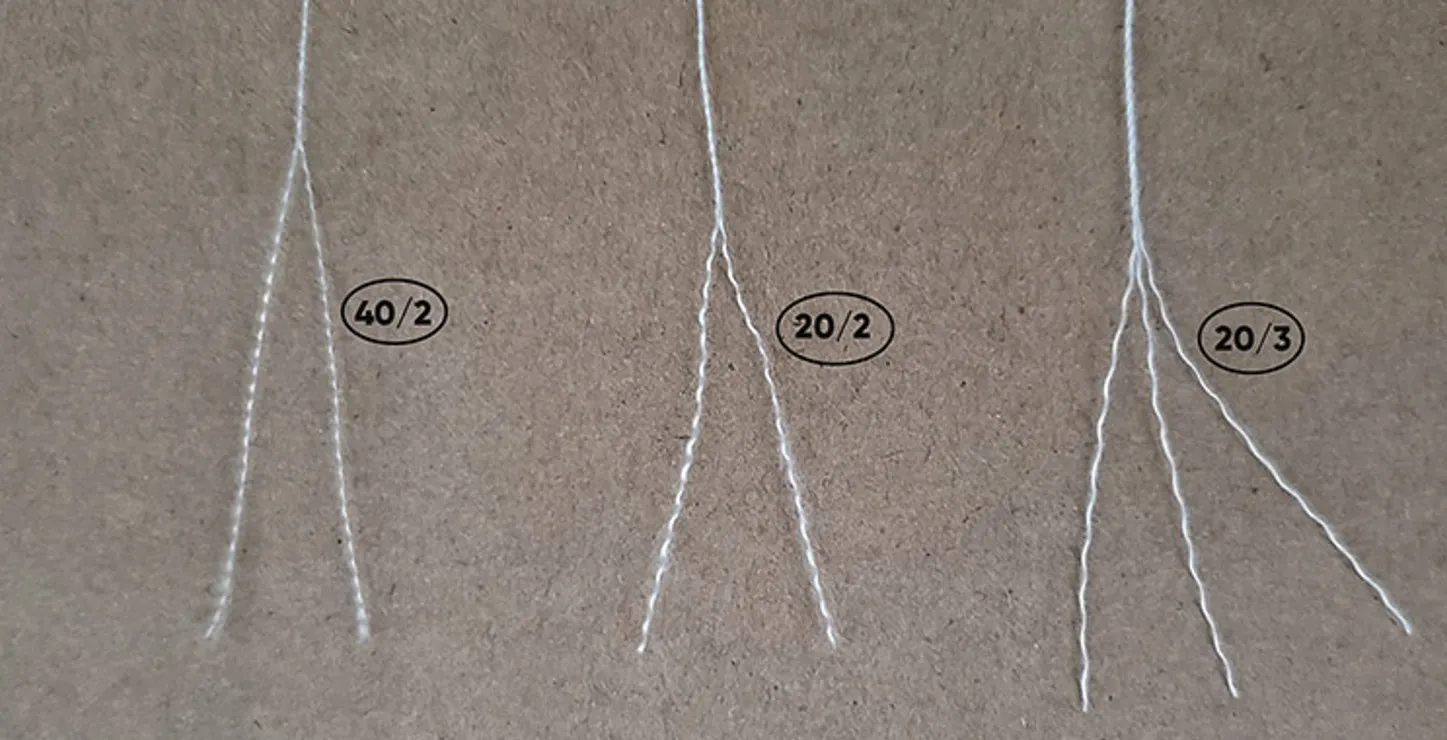

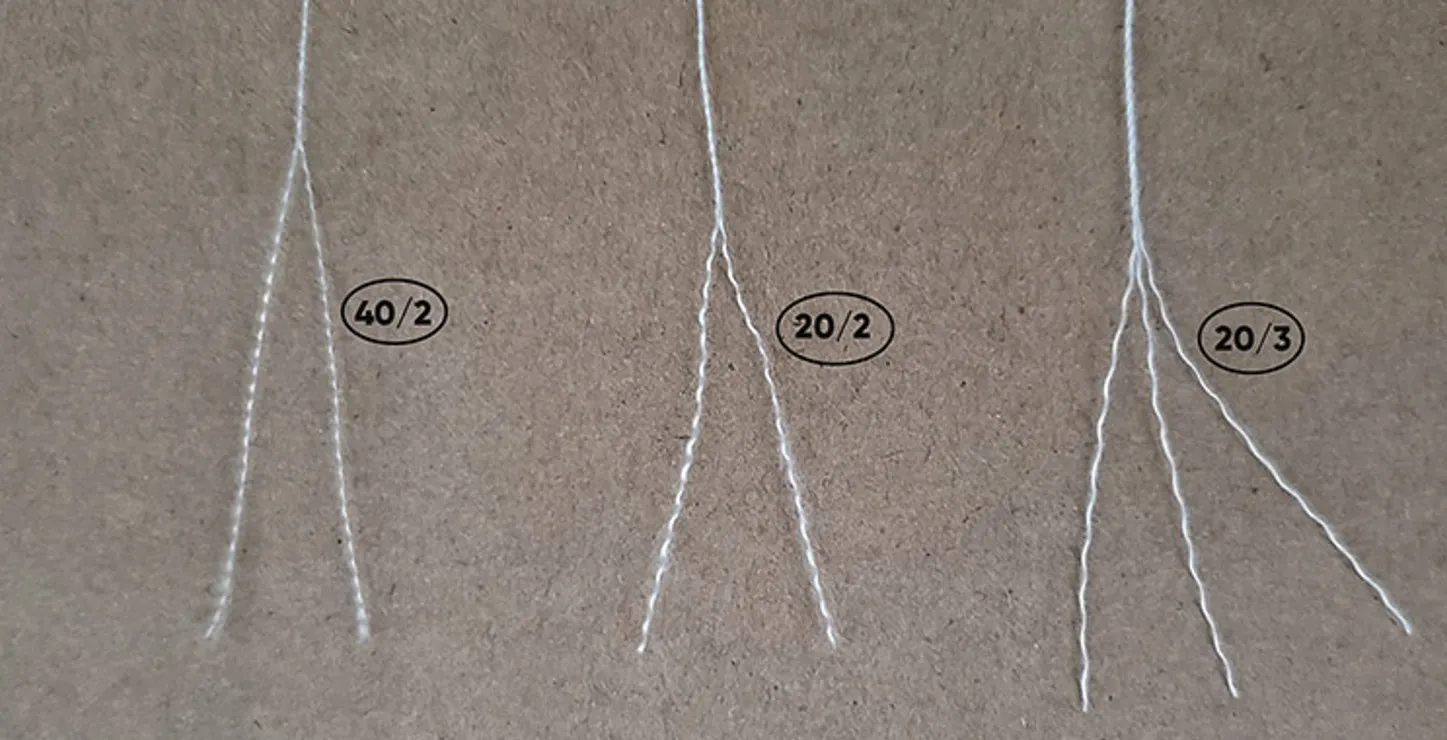

Every spool of sewing thread carries a number code — a technical shorthand describing its internal structure. Learning to read this code helps you instantly understand how fine or strong a thread is, even before testing it. In a code like 40/2 or 60/3:

- The first number (40 or 60) represents the fineness of each single filament. A higher number means a finer filament.

- The second number (2 or 3) shows how many of those fine filaments are twisted together to form one completed thread.

So, a 40/2 thread has two filaments of fineness 40 twisted together, while 60/3 has three finer filaments of 60. This combination influences both the look and the strength of the thread.

Comparison: 40/2 vs 60/3:

Once you know what the code means, the next step is to compare the two: how does a “40/2” thread stack up against a “60/3”? What are the differences in filament fineness, how many filaments are used, how that affects the result for strength, appearance, seam bulk and suitability. These differences might seem small on paper, but they matter a lot in the final product.

- Filament fineness: For 40/2, the fineness is “40”; for 60/3, the fineness is “60”. Because 60 > 40, each individual filament in 60/3 is finer than in 40/2.

- Number of filaments twisted: 40/2 uses 2 filaments; 60/3 uses 3 filaments. So even though each filament is finer, 60/3 uses more of them.

- The result: 60/3 tends to give a thread that is finer in filament size (so good for more delicate sewing) and stronger (because three filaments) than 40/2 – though this also depends on materials, production quality, and other factors.

| Feature | Thread 40/2 | Thread 60/3 |

|---|---|---|

| Filament Fineness | 40 – moderate | 60 – fine |

| # of Filaments | 2 filaments | 3 filaments |

| Thickness | Medium | Fine |

| Strength | Strong, general-purpose | Slightly stronger, smoother |

| Fabric Type | Medium-weight, everyday apparel | Lightweight, delicate fabrics |

| Appearance | Visible, defined seams | Smooth, subtle seams |

| Needle Size | 11–12 | 10–11 |

| Cost Efficiency | Higher efficiency | Higher finesse |

| Best For | Shirts, pants, uniforms | Dresses, blouses, luxury fashion |

Practical Implications for Production:

Knowing the technical differences is useful—but even more important is knowing what they mean in actual production. How does choosing 40/2 vs 60/3 affect sewing machine settings, needle size, seam appearance, fabric compatibility, cost and durability of the finished garment? This section translates specs into real-world effects.

- Suitability for fabrics: 40/2 is often used for “normal” garment fabrics — good balance between strength and thickness. 60/3 is more suited to fabrics where a finer thread is beneficial yet you still need decent strength — e.g., lighter fabrics, more refined stitching.

- Appearance and seam quality: A finer filament thread like 60/3 will produce finer, less visible seams in some applications; also less “bulk” in the seam.

- Strength & durability: Because 60/3 has more filaments twisted (3 vs 2), it may offer improved strength/performance in certain applications compared to 40/2 (all else equal).

- Machine & needle considerations: Using a finer filament thread may require adjustments in machine settings (tension, needle size, etc) to avoid breakage, tension issues or skipped stitches.

How to Choose Based on Your Needs:

Finally, with all the information in hand, you’ll want clear guidance: Which thread should you pick for which job? For standard garments with typical fabrics, vs lighter fabrics or high-end finishes? What trade-offs are there between cost, appearance and durability? This factor helps you decide.

- If you are sewing a general garment with standard fabric, oriented for cost-efficiency and acceptable seam appearance → 40/2 is often sufficient.

- If you are working with lighter, fine fabrics or need cooler aesthetics (less visible thread) or finer seams while still maintaining strength → 60/3 may be preferable.

- Always test: machine compatibility, fabric behavior, stitch quality, seam durability.

Final Thoughts / Conclusion

Though they seem similar, thread 40/2 and 60/3 serve different needs. The difference lies in the details — the number of filaments, their thickness, and the finish they produce. If you want sturdy, easy-to-use thread for general garments, go with 40/2. If you aim for precision, refinement, and elegance, choose 60/3. Mastering the meaning behind these numbers helps you produce cleaner seams, reduce thread waste, and elevate your garment quality to a professional level.