As we know, the textile and garment industry fundamentally involves many processes – spinning fiber, weaving cloth, dyeing, printing, finishing and more – all of which are essential to turn raw fiber into finished fabric or clothing. At the same time, this industry is accompanied by numerous safety and health concerns. Specifically, these issues include exposure to cotton dust and other organic dust, handling of numerous chemicals in fabric dyeing, the ergonomic stress on musculoskeletal systems, exposure to noise, and other worker-health concerns. This article helps you understand each of these issues in detail.

Safety & Health Issues in the Garment Industry

Exposure to Dust and Fabric Dust

During spinning and fiber-handling, cotton tends to generate dust, sometimes mixed with pesticide residues and soil. These airborne particles can enter workers’ lungs, potentially leading to serious lung conditions the most common being “brown lung”. It has also been observed that workers exposed to cotton dust tend to suffer from chronic cough.

=> Related Article: Safe Chemical Transfer Process in the Garment Industry

Chronic cough differs from ordinary asthma in that the cough lasts for more than three months. Due to inhalation of cotton dust that causes allergic reactions and throat irritation, dry cough results. One particular study by A V Hinson, involving 656 workers exposed and 113 non-exposed workers, found that nearly 7.2% experienced chest constriction and 9.9% had breathing difficulties.

Exposure to Chemicals

The relationship between dyes/finishing chemicals (for cleaning, softening and finishing fabrics) often involves exposure to certain chemicals. These include benzidine, optical brighteners, solvents and fixatives, formaldehyde and various antibacterial agents. When exposed to formaldehyde, it may lead to brain cancer, lung cancer, blood cancers. It is not necessary to have direct skin contact simply inhaling these chemicals can cause serious health issues.

=> Related Article: Safety and Health in the Textile and Garment Industry

For instance, dimethylformamide (used in aramid fibers) is a solvent with good performance, used in large shares of military-grade fabrics. N,N-Dimethylformamide is deemed toxic to many animals (cats, rabbits, rats). It is a known carcinogen, wholly responsible for liver toxicity, and also affects female reproductive systems and leads to many birth defects. For instance, ethylene glycol (commonly used in polyester fiber production) is a solvent that helps create smooth, durable, and wrinkle-resistant fabrics. Although it is much less toxic than dimethylformamide, prolonged exposure without proper ventilation can still cause mild irritation to the eyes and throat. Therefore, maintaining good air circulation is recommended to ensure worker safety.

Exposure to Noise

In the textile industry, noise is defined as any unwanted sound. If noise levels are high, especially in production areas, it can cause lifelong hearing loss. The main types of noise include continuous noise, impact noise, and intermittent noise. Exposure to higher than usual noise levels is common in the textile industry. In the spinning and weaving sections, they generate very high noise levels.

=> Related Article: How to Get a Great T-Shirt Print Even If You Can’t Design

This may even lead to hearing loss and many other problems, such as sleep disorders, elevated blood pressure, fatigue, absenteeism, irritability, changes in heart rate and blood pressure.

Some Other Issues

These problems are especially common in many developing countries, where many workers must labour in unsafe and unhealthy conditions: cramped working spaces, inadequate lighting and ventilation. Many garment-industry workers suffer from musculoskeletal disorders such as carpal tunnel syndrome, lower back pain, shoulder pain, neck pain.

=> Related Article: What Is the Difference Between T/T and L/C for Importers?

Ways to Address These Issues

Improving safety and health in the textile and garment industry requires a mix of engineering controls, management commitment, and worker awareness. Each risk—whether from dust, chemicals, noise, or ergonomic strain—can be minimized through a systematic and proactive approach. Below are key measures factories should take to protect workers and create a healthier workplace.

=> Related Article: Tech Pack to Finished Garments: A Complete Production Timeline Guide (8–16 Weeks)

Control of Dust and Air Quality

Dust generated during spinning, weaving, and cutting can be reduced by:

- Installing efficient air filtration systems that capture lint, fiber particles, and other fine dust before it spreads.

- Using local exhaust ventilation (LEV) near sewing machines, carding, and weaving areas to keep airborne fibers at safe levels.

- Regular wet cleaning or vacuuming floors and surfaces to prevent dust buildup, instead of dry sweeping which stirs particles into the air.

- Providing workers with suitable masks or respirators, especially in high-dust areas such as spinning, carding, or cotton-opening sections.

- Maintaining humidity levels between 60–70% to reduce airborne lint and prevent fabric static.

=> Related Article: How to Calculate the Total FOB Cost of Custom Clothing Production

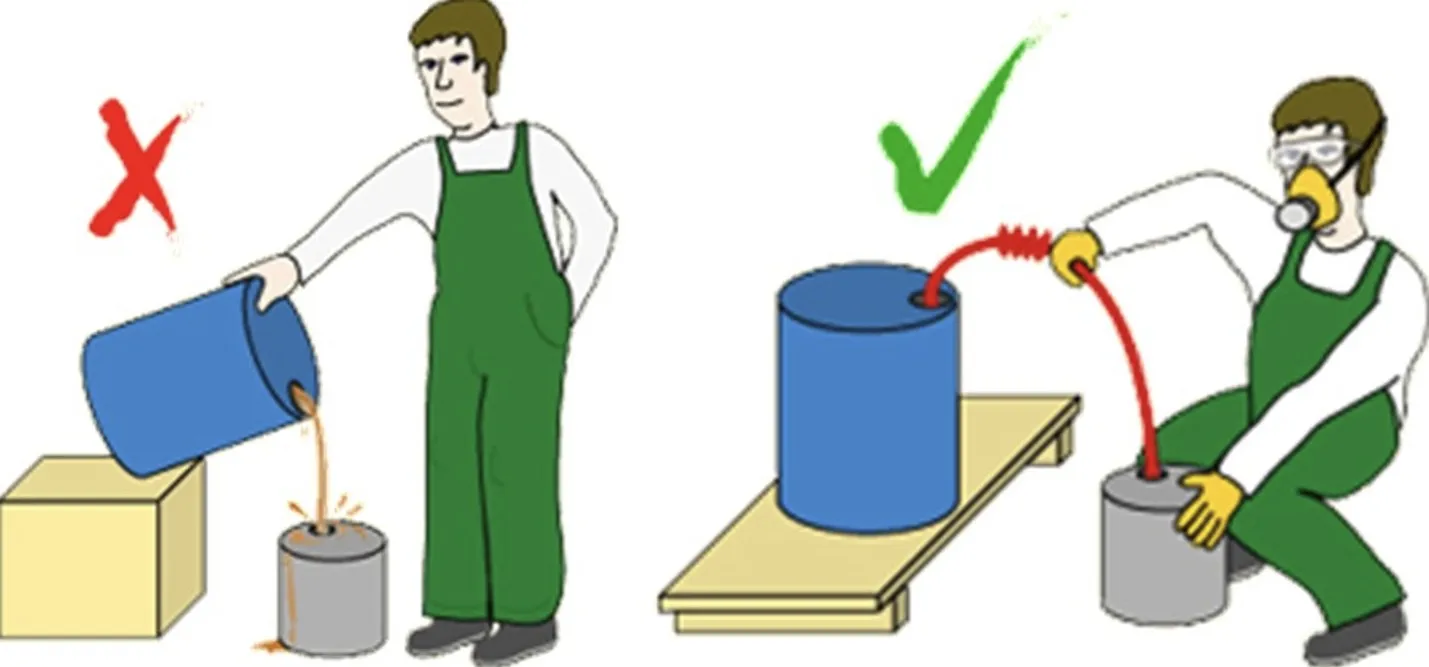

Chemical Safety Management

Chemicals used for dyeing, printing, washing, or finishing must be handled responsibly to reduce health risks. Some effective measures include:

- Substituting safer alternatives whenever possible — for example, using ethylene glycol instead of more toxic solvents.

- Proper labeling and storage of all chemical containers with safety data sheets (MSDS) easily accessible.

- Providing personal protective equipment (PPE) such as gloves, goggles, and aprons for workers who handle or mix chemicals.

- Training employees on safe chemical handling, emergency procedures, and the importance of ventilation.

- Installing proper ventilation systems in dyeing and finishing sections to disperse fumes and vapors.

- Setting up an emergency wash station or shower area near chemical-handling zones.

=> Related Article: How to Find a Garment Manufacturers in Vietnam

Noise Reduction and Hearing Protection

Noise is one of the most common hazards in textile plants. Effective prevention can be achieved through:

- Routine maintenance of machines to reduce unnecessary vibration or friction noise.

- Installing acoustic barriers or sound-absorbing panels around noisy equipment such as looms, compressors, and generators.

- Implementing noise zoning, where high-noise areas are clearly marked and access is limited.

- Providing earplugs or earmuffs to all employees working in noisy environments.

- Rotating job assignments to minimize the duration of noise exposure for any single worker.

- Conducting periodic hearing tests to detect early signs of hearing loss.

=> Related Article: What’s the Difference Between a Tech Pack and a Spec Sheet?

Ergonomics and Workplace Design

Repetitive tasks, prolonged sitting, or awkward postures can cause chronic pain. Employers can prevent this by:

- Providing adjustable chairs and tables to fit different worker heights and comfort levels.

- Redesigning workstation layouts so tools and materials are within easy reach, reducing unnecessary stretching or twisting.

- Encouraging regular micro-breaks to stretch and relax muscles, especially for sewing and inspection workers.

- Offering ergonomic training to help employees maintain correct posture and safe lifting techniques.

- Using anti-fatigue mats for workers who stand for long periods, such as in cutting or pressing areas.

=> Related Article: Why the Bill of Materials (BOM) Matters

Fire Safety and Emergency Preparedness

Garment factories should always be ready to respond to emergencies. Key actions include:

- Installing and maintaining fire extinguishers, alarms, and sprinkler systems across all production areas.

- Keeping exits clear and well-marked, with emergency lighting in corridors and stairways.

- Conducting regular fire drills to ensure all employees know evacuation routes and procedures.

- Appointing trained safety wardens responsible for checking equipment and coordinating responses during emergencies.

- Ensuring electrical wiring and machines are regularly inspected to prevent short circuits or overloads

=> Related Article: How to Start a Garments Business and Sell More Clothes

Health Monitoring and Worker Welfare

To sustain long-term safety culture, health management should be part of daily operations:

- Conducting regular medical check-ups for workers exposed to dust, chemicals, or high noise levels.

- Providing on-site first aid rooms with trained medical staff available for minor injuries or illnesses.

- Supplying clean drinking water and proper ventilation to maintain comfort and reduce fatigue.

- Promoting nutrition and hygiene education to strengthen workers’ immunity and reduce sickness absence.

- Establishing open communication channels so employees can report unsafe conditions without fear.

Building a Safety Culture

Finally, safety is not just about rules—it’s a mindset shared by everyone in the workplace.

- Management must set clear policies that make worker safety a top priority equal to production targets.

- Regular safety training and refresher courses should be part of every employee’s routine.

- Reward and recognition programs can motivate teams that consistently follow safety practices.

- Continuous improvement — by reviewing incidents, collecting feedback, and updating procedures, keeps safety standards evolving with new technologies.

Conclusion / Final Word

In summary, dealing with safety and health issues is a top priority in the textile and garment industry. This becomes even more important given the large number of employees in this field. As discussed in this article, the industry poses many health risks. Industry management must seek solutions to protect workers from hazardous environments. Addressing these issues is essential for improving working conditions and safeguarding workers’ health.