What Is High-Tenacity Nylon Fabric? Benefits, Pros and Cons

High-tenacity nylon sounds like a buzzword, but it’s a real material upgrade that can decide whether a jacket lasts one season or five. In simple terms, it’s nylon yarn engineered to be stronger for its size, so fabrics can resist tearing and rubbing without turning bulky. That’s why brands use it for commuter shells, travel jackets, and gear that gets scraped by straps, seats, and daily friction. Still, it isn’t a perfect “super fabric” since moisture behavior, stretch, cost, and construction quality can change the outcome. In this article, we’ll break down what high-tenacity nylon is, how it’s measured, and the true pros and cons so you can choose it for the right jobs, not just the right label.

What is High-Tenacity Nylon?

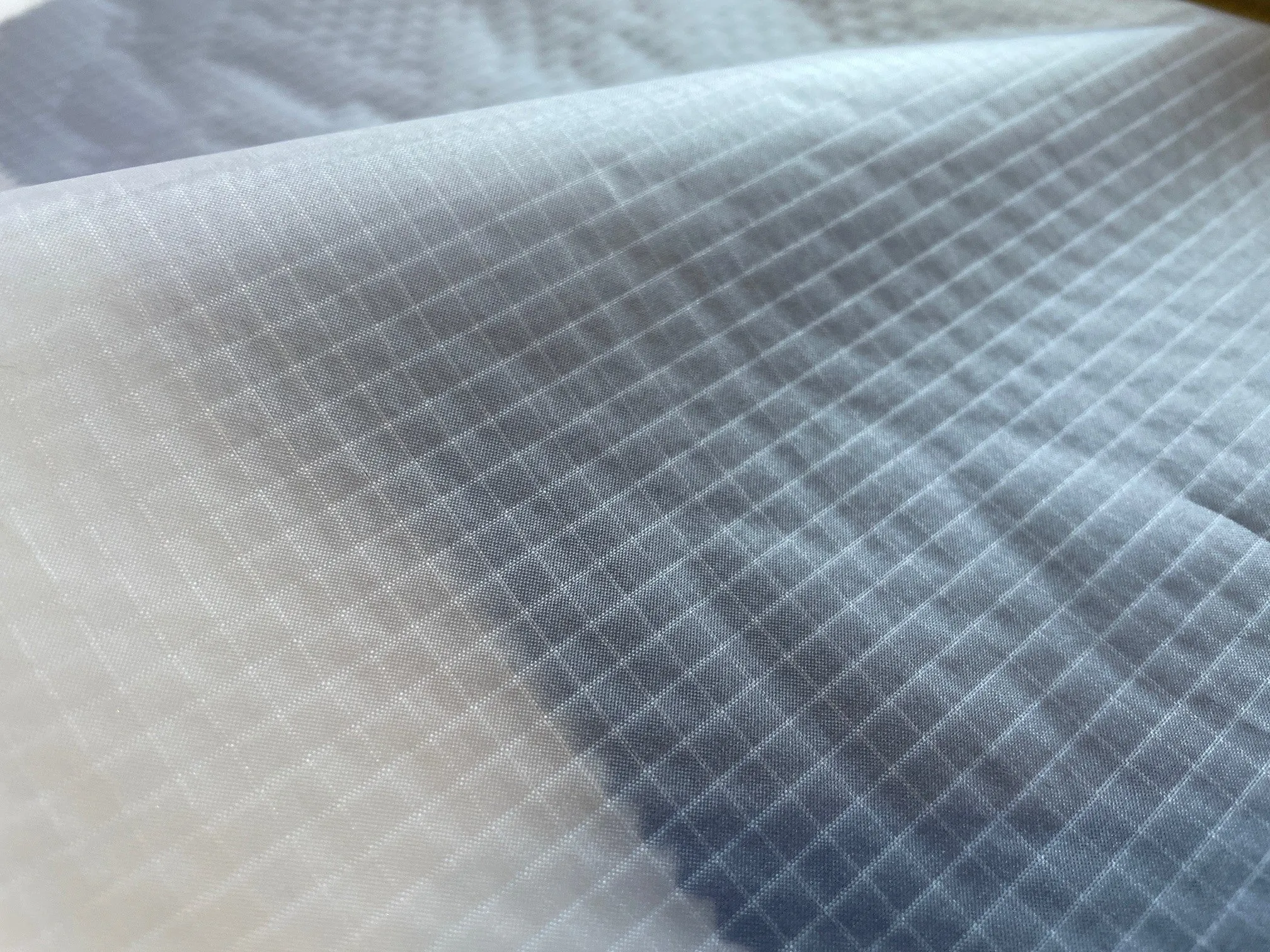

High-tenacity nylon is nylon yarn made to be much stronger than regular nylon. “Tenacity” means how much force a yarn can take before it breaks, compared to its thickness. It is usually written as g/denier (g/d) or cN/tex. Most high-tenacity nylon used in tough fabrics is based on nylon 6 or nylon 6,6. Nylon 6,6 often shows up in rugged “CORDURA-type” fabrics because it’s known for durability in abrasion-heavy use.

How it’s made (simple version)

Factories make high-tenacity nylon by controlling the spinning and drawing steps so the polymer chains line up better. When the molecules are more aligned, the yarn can handle more load before it snaps. (That’s the whole “high tenacity” trick.)

How tenacity is measured

- Tenacity = breaking force divided by linear density.

- Common units: g/denier (g/d) and cN/tex.

- Denier and tex are both “mass per length” units (just different scales).

Pros & Cons of High-Tenacity Nylon

Pros

High-tenacity nylon earns its reputation because it solves a very real problem: lightweight fabrics often fail first where life keeps rubbing them. When you upgrade to high-tenacity yarn, you’re not just buying “strong,” you’re buying strength that lasts under repeated stress. For jackets, that can mean fewer tears from snags, slower wear from backpack straps, and a shell that keeps its shape and look longer. Still, these benefits only show up when the fabric build (denier, weave, finish) matches the job, not when you rely on the label alone. In the next sections, we’ll walk through each key advantage and where it truly matters in real-world wear.

- Very strong for its weight: You get high tensile strength without needing a super thick fabric. That’s why it’s popular in packs, straps, and rugged shells.

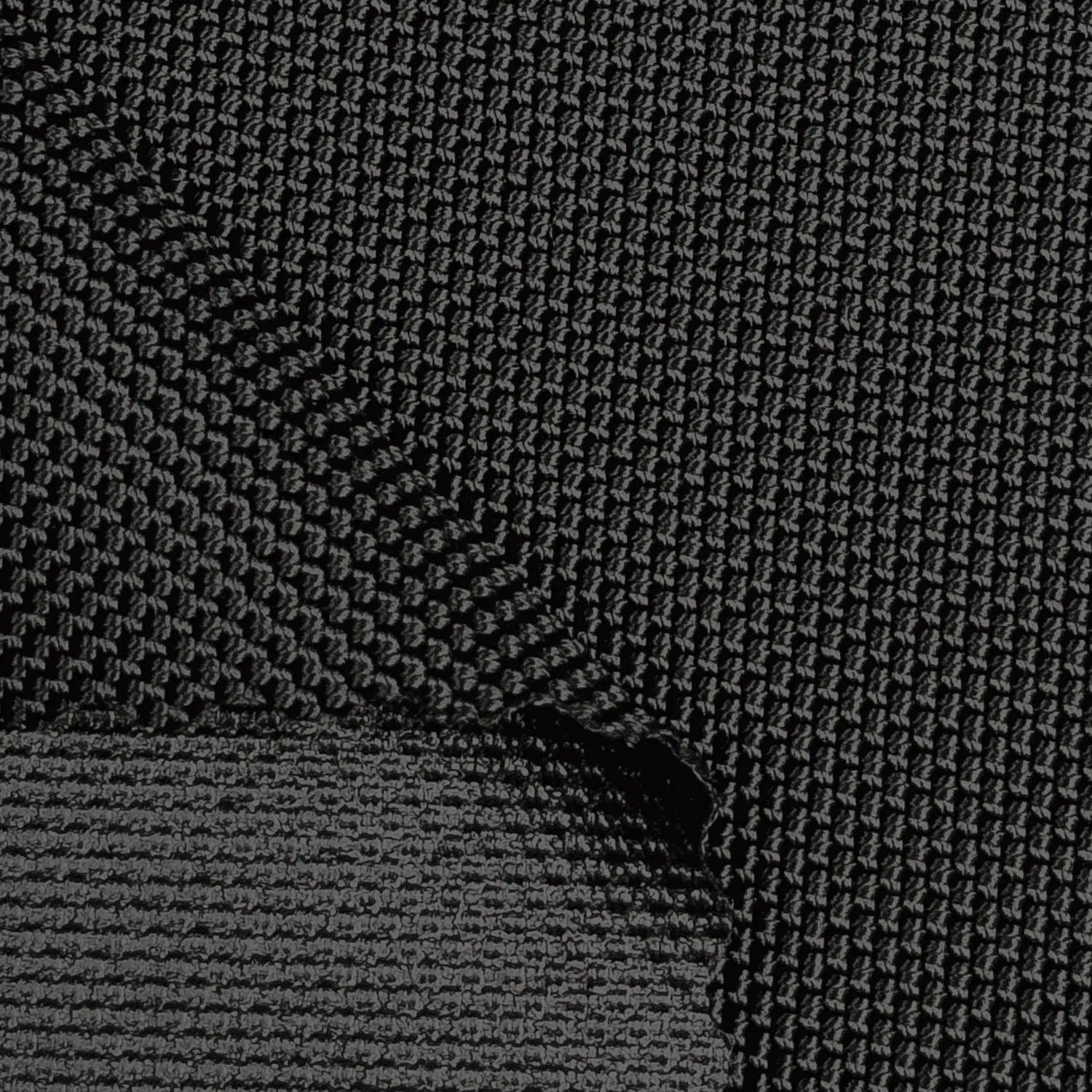

- Great abrasion resistance (rubs less “to death”): This is the headline benefit for commuter jackets and travel gear that constantly meets backpack straps and seat friction.

-

Good tear resistance: High-tenacity yarns help fabric resist ripping when snagged, especially when paired with the right weave.

-

Durable hand feel options: It can be made as smooth filament yarns or textured yarns. Brands can tune the “technical” look and feel.

-

“Punches above its weight” options exist: Some lines (like lightweight CORDURA directions) aim for strength at lower deniers, which helps when you want tough but not bulky.

Cons

High-tenacity nylon has real muscle, but it also has trade-offs that can surprise brands after production. The biggest mistake is treating it like a “perfect” fabric, because durability on paper doesn’t always mean comfort, stability, or value in real use. In wet or humid conditions, nylon can behave differently than polyester, and that can affect feel and performance. Also, toughness can tempt brands into heavier builds, which may clash with a “lightweight jacket” promise. In the sections below, we’ll break down the main downsides so you can decide when high-tenacity nylon is worth it and when it’s the wrong tool.

- It can absorb moisture and change behavior: Nylon is hygroscopic. Moisture regain is often cited around a few percent for nylon, and this can affect feel and mechanical behavior.

- Wet stretch can be a real problem: Compared with polyester, nylon can absorb more moisture and may stretch more when wet. That matters for items that must stay tight and stable.

- Not always “ultralight” in the real world: Yes, it’s strong for its weight. But many high-tenacity fabrics become heavy because brands choose higher denier, dense weaves, or coatings for durability. So “lightweight” depends on the full build, not the yarn alone.

- Cost can be higher: High-tenacity yarns and durable constructions can raise fabric cost. If your jacket is fashion-only and rarely sees abrasion, you may be paying for armor your customer won’t use.

- Strength isn’t the whole story: A tough yarn won’t save weak seams, zippers, or bad pattern stress points. Many products fail at construction before the fabric “gives up.” (This is where brands get surprised.)

Where high-tenacity nylon makes the most sense

Best matches

This material has a clear home: places where friction and abuse are normal. Commuter shells, travel jackets, and utility outerwear love it because the fabric keeps its looks longer. It also makes sense for outdoor lines that meet rocks, straps, and rough handling. But it’s not the best answer for every jacket style. If your customer wants soft drape or ultra-fast drying, another fabric may fit better.

- Commuter shells (backpacks, seat contact, daily wear)

- Travel jackets (constant abuse, packing, straps)

- Utility outerwear with a technical look

When it may be the wrong choice

- You need low water absorption / high wet stability (polyester may win)

- You want the absolute lightest feel and don’t need abrasion resistance

- Your product is delicate fashion where drape matters more than toughness.

Bottom line / Final Words

High-tenacity nylon is a strong choice when you want a jacket that stays alive through straps, friction, and hard daily wear. The upside is durability and strength for the weight. The downside is moisture behavior, possible stretch, and higher cost if your customer doesn’t need toughness. Also, fabric strength can’t rescue weak construction. If you match the fabric to real use, it’s a win.

Our Contact Information – MEKONG GARMENT FACTORY

- Vietnam Phone: +84 947 729 829

- WeChat: +84 947 729 829

- WhatsApp: +84 947 729 829

- Email: hanh@kimmy.vn