When you buy clothes online, you often see this note under the size chart: “Size is manually measured. A difference of 1–3 cm may occur. Returns are not accepted for this reason.” This is not a random excuse. It is based on international garment tolerance standards. So what do tolerances really mean, and what range is considered reasonable? Unlike machines or metal parts, clothing cannot be made with perfect precision. Small size differences are normal and expected in the apparel industry.

Why Clothing Sizes Always Have Tolerances

Fabric Instability

Fabric is alive in a way machines are not. Different fabrics stretch, relax, and shrink in different ways. Cotton, wool, viscose, and blends can all react differently to heat, steam, ironing, or washing. Even after finishing, garments may slightly change size once they are pressed or washed. This natural behavior makes exact sizing impossible.

=> Related Article: How Does a Prototype Sample Affect My Clothing Production Cost?

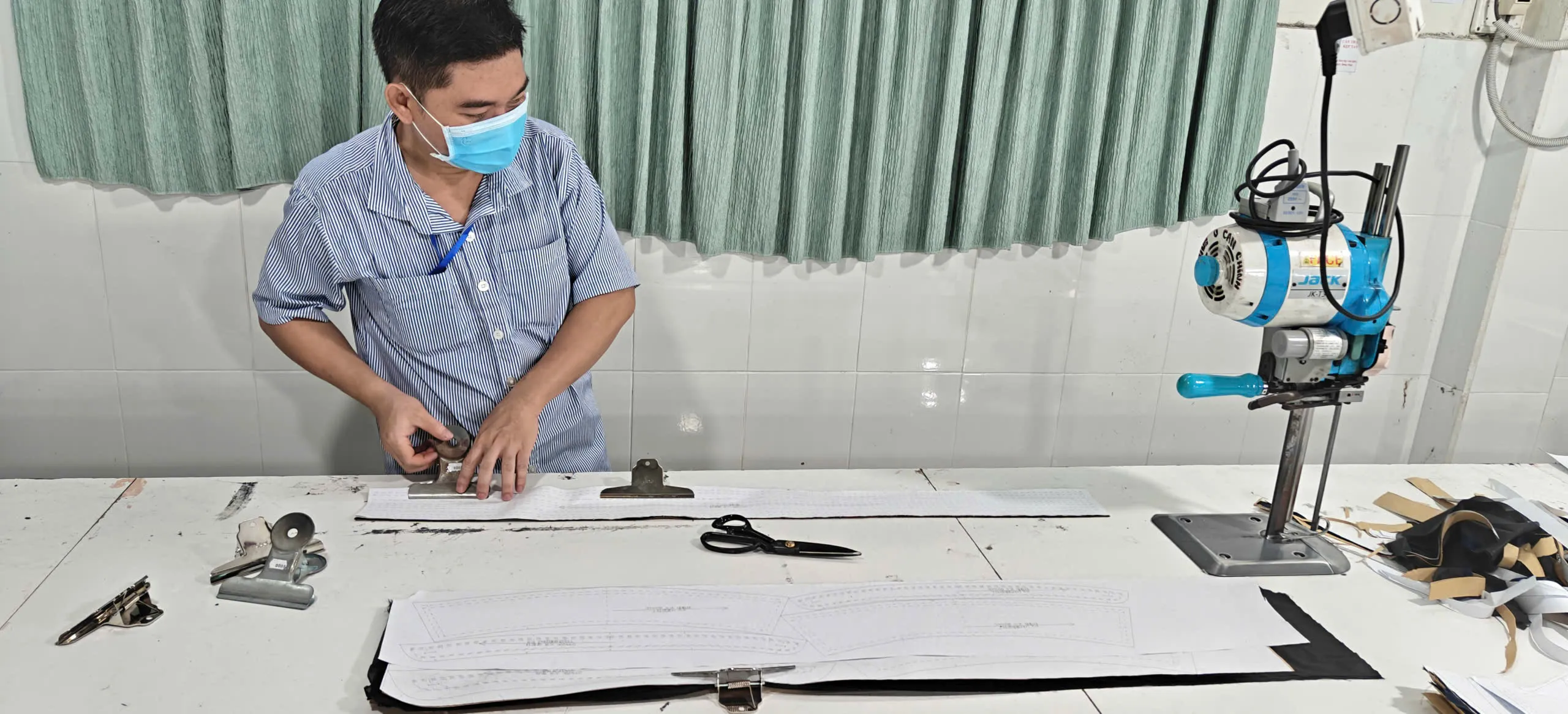

Manual Cutting

Before sewing begins, fabric must be cut. In most garment factories, cutting is still done by people, not fully automated machines. Even with templates and markers, small deviations are unavoidable. A few millimeters lost or gained during cutting can affect the final measurement.

Stitching and Sewing Process

Sewing is still a labor-intensive process in most garment factories today. The final size of a garment depends on seam width, stitch tension, and the operator’s skill. Even when following the same pattern, different sewing techniques can create slight size changes. This is why tolerances are always built into clothing production.

Most garments today are still sewn by hand-operated machines. The final size depends on:

- Seam allowance

- Stitch tension

- Operator skill level

Different sewing workers may produce slightly different results, even with the same pattern. This is normal across all factories worldwide.

Measurement Methods

The way a garment is measured can strongly influence the final numbers. Different starting points, pulling strength, and garment conditions can all change the result. A flat garment, a worn garment, and a washed garment will never measure exactly the same. Because measurement is done by hand, small differences are completely normal. How a garment is measured also affects the result. For example:

- Measuring from different starting points gives different numbers

- Ironed garments measure differently from wrinkled ones

- Pulling harder or softer changes the size

- Measuring flat vs. on a model gives different values

- New, washed, and worn garments never measure exactly the same

Because of this, measurement is never 100% fixed.

What Tolerance Is Considered Acceptable?

In international apparel production, a tolerance of around ±2 cm is generally accepted. Depending on the product type and fabric, many brands allow:

- ±1 cm for small items

- ±2 cm for most garments

- Up to ±3 cm for heavier or looser styles

This is why retailers clearly state tolerance limits in their size charts.

Final Thoughts / Conclusion

Garment tolerances are not flaws they are part of how clothing is made. Fabric behavior, manual cutting, sewing, and measuring methods all affect final size. As a result, small differences are normal and unavoidable. For retailers and buyers alike, understanding international tolerances helps set realistic expectations and avoids unnecessary disputes. A size difference of about 2 cm is widely recognized as reasonable across the global clothing industry.