In garment manufacturing, hundreds of machines work together to turn raw fabric into finished clothing. To keep production efficient, each piece of equipment has its own symbol and function used in technical layouts and operator guides. Understanding these symbols not only helps workers read factory blueprints correctly but also improves communication and workflow among departments.

The following sections explain the most common types of sewing machines and supporting equipment used in factories today including what each machine does and why it’s essential in garment production.

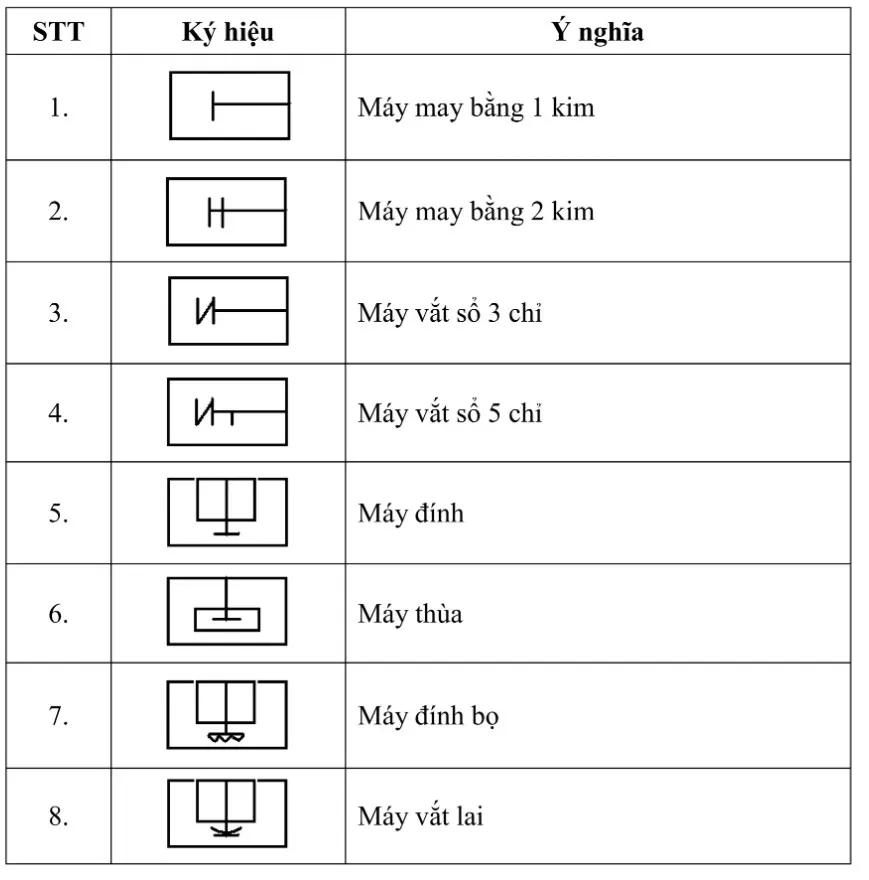

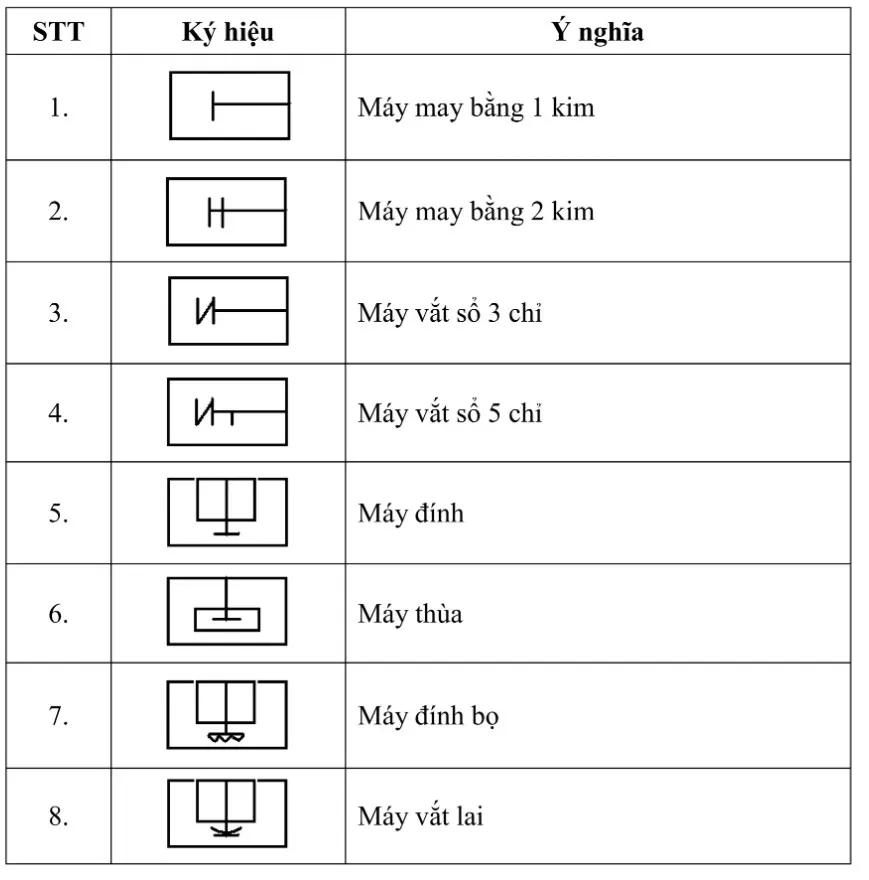

Sewing Machines and Seam Finishing Equipment

Before any garment reaches the finishing stage, it must first go through precise stitching operations. Sewing machines form the backbone of every garment factory, each one designed for a specific task — from simple straight stitching to overlocking, hemming, or attaching buttons. Knowing the difference between these machines helps workers choose the right tool, maintain quality control, and increase production speed. Below is a closer look at the most common types of sewing and seam-finishing machines used across the industry.

1 – Single-needle Sewing Machine

This is the most basic and widely used type of sewing machine. It uses one needle to create a clean, straight stitch, perfect for general sewing operations.

- Function: Ideal for light to medium-weight fabrics like shirts, blouses, and uniforms.

- Advantage: Produces neat seams with consistent stitch quality and easy maintenance.

2 – Double-needle Sewing Machine

A double-needle machine works with two needles to produce two parallel stitch lines at once. It’s especially common in decorative or reinforcement sewing.

- Function: Strengthens key seam areas or adds aesthetic topstitching on jeans and outerwear.

- Advantage: Saves time while enhancing both the look and durability of the garment.

3 – Thread Overlock (Serger) Machine

This machine trims fabric edges while stitching them simultaneously, preventing fabric from fraying.

- Function: Commonly used on knitwear and stretch fabrics.

- Advantage: Delivers smooth, secure edges and a professional inside finish.

4 – 5 thread Overlock Machine

A 5-thread overlock combines an overlock stitch and a straight stitch in one operation.

- Function: Ideal for heavy-duty garments requiring strong seams, such as denim or workwear.

- Advantage: Increases seam strength and reduces production time.

5 – Button Attaching Machine

A specialized machine for securely attaching buttons and snap fasteners.

- Function: Ensures accurate placement and tight stitching.

- Advantage: Improves consistency and saves manual labor.

6 – Buttonhole Machine

Used to form uniform buttonholes with reinforced edges.

- Function: Creates clean openings for buttons on shirts, jackets, or trousers.

- Advantage: Prevents fabric from tearing and ensures smooth button operation.

7 – Bartack Machine

This machine produces short, tight zigzag stitches to reinforce stress points.

- Function: Strengthens pockets, belt loops, and side seams.

- Advantage: Extends garment life by preventing fabric wear and tear.

8 – Hemming Machine

Used for finishing bottom edges or cuffs neatly.

- Function: Folds and sews fabric edges for a clean and secure hemline.

- Advantage: Delivers a polished appearance and prevents unraveling.

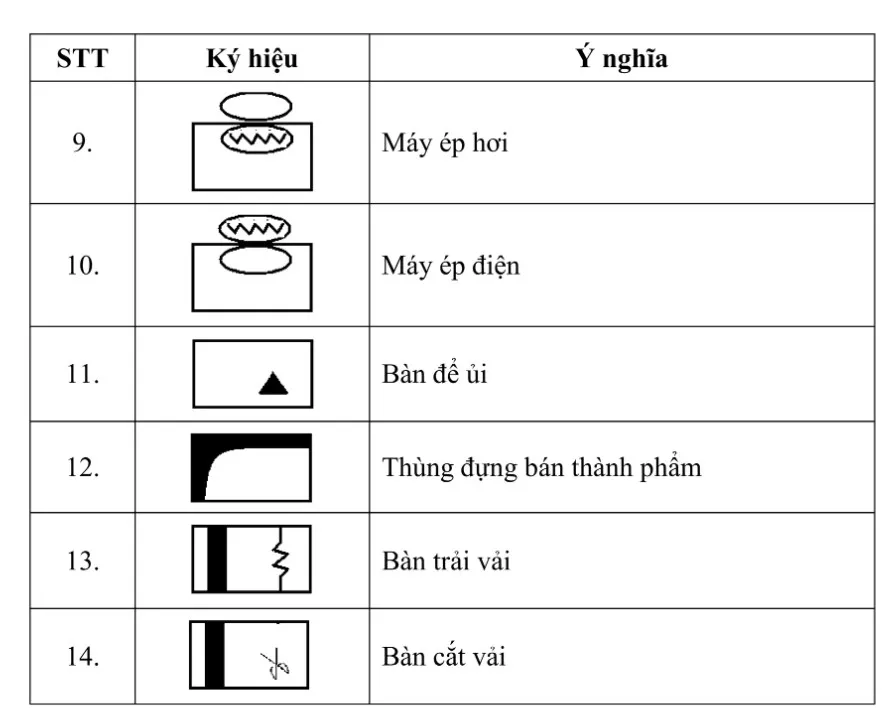

Supporting Equipment for Sewing and Product Finishing

After sewing, garments move to the finishing stage, where they’re pressed, shaped, checked, and organized before packaging. Supporting equipment plays a vital role in this phase ensuring garments look professional, meet shape standards, and stay organized throughout production. The tools below may not perform stitching, but they are equally important for maintaining efficiency and product quality in every sewing line.

9 – Steam Press Machine

A steam press uses pressure and heat from steam to flatten or shape garments.

- Function: Removes wrinkles, sets seams, and gives garments their final form.

- Advantage: Produces crisp, lasting finishes and enhances the overall appearance.

10 – Electric Heat Press

Similar to a steam press but relies on electric heating elements instead of steam.

- Function: Used for pressing dry fabrics or applying heat transfers like patches or prints.

- Advantage: Provides stable, adjustable heat control and is energy-efficient.

11 – Ironing Table

Every finishing section needs a flat, stable ironing surface to support pressing work.

- Function: Provides a safe, heat-resistant area for steam or dry ironing.

- Advantage: Improves comfort and accuracy for operators during the finishing process.

12 – Work-in-Progress (WIP) Bin

In large-scale production, garments move between many operators. WIP bins keep semi-finished items organized between processes.

- Function: Holds garments waiting for the next operation or inspection.

- Advantage: Keeps workflow smooth, prevents mix-ups, and saves time.

13 – Fabric Spreading Table

Before fabric can be cut, it must be spread out flat without wrinkles. This table makes that possible.

- Function: Ensures fabric layers are even and aligned before cutting.

- Advantage: Improves precision and reduces material waste during cutting.

14 – Fabric Cutting Table

A specialized workstation designed for cutting fabric according to production patterns.

- Function: Provides a large, flat surface for precise cutting using manual or automatic tools.

- Advantage: Increases accuracy and efficiency, especially in mass production.

The Importance of Machine Symbols in Garment Production

Understanding machine symbols isn’t just a technical skill, it’s part of a universal language that keeps factories running smoothly. These symbols appear in layout maps, maintenance manuals, and training materials, allowing staff to identify equipment quickly and work safely. Standardized symbols also help factories train new workers faster, minimize communication errors, and ensure that every step, from cutting to packaging stays consistent and efficient.

Final Words / Conclusion

Machine symbols and their corresponding functions are more than just labels — they represent a shared system of understanding in the global garment industry. When properly used, they help every worker, from beginner to expert, stay aligned toward the same production goals: quality, efficiency, and precision.