How to Turn a Clothing Idea into a Professional Tech Pack

Every great garment starts as an idea. You picture the shape, the fabric, and how it will feel when someone wears it. But factories cannot work from imagination alone. They need clear instructions, exact numbers, and unambiguous details. The step that connects creativity to production is the tech pack, and mastering it is essential for any serious fashion brand.

Turning an idea into a professional tech pack means breaking your vision into precise, measurable information that manufacturers can follow without guessing. This process includes defining the concept, drawing technical flats, listing materials, detailing construction methods, and setting clear quality rules. A strong tech pack becomes a shared language between you and your factory. Brands that invest time in this step often see faster sampling, fewer errors, and smoother production overall.

Below is a step-by-step guide to help you transform inspiration into a document that factories can execute with confidence.

How Do You Define a Strong Design Concept First?

Before writing any measurements or technical notes, your idea needs direction. A clear design concept keeps every decision aligned, from fabric choice to stitching method. Without this clarity, tech packs become confusing and inconsistent.

Start by writing a simple design brief. Describe who the garment is for, how it will be used, and what problem it solves. Add references such as colors, silhouettes, fabric textures, or lifestyle images that match your goal. This early clarity helps everyone designer, developer, and factory understand what the product is meant to become. A well-defined concept also prevents scope creep. When decisions come up later, you can ask one simple question: does this support the original idea? Example: Clear design concept:

- Vague idea: “Comfortable pants”

- Clear concept: “Lightweight office trousers for men aged 25–40, designed to look formal but stretch and move like athletic wear.”

What questions should your concept clearly answer?

Your design concept should leave no confusion about the basics:

- Who will wear this garment?

- What function does it serve in daily life?

- In what situation or season will it be used?

- What makes it different from similar products on the market?

Clear answers give factories context, not just instructions. That context leads to better execution. Example answers:

- Who: Office professionals who sit and move all day

- Function: Professional appearance with high mobility

- When/Where: Daily workwear, indoor and light outdoor use

- Why different: Stretch fabric, hidden elastic waistband, clean tailoring

How do you turn inspiration into practical details?

Inspiration must become specific. If you like a “workwear look,” identify what that means in real terms pocket shapes, fabric weight, hardware style, or seam types. Each inspired detail should be translated into something measurable or selectable. Once defined, these elements can be documented clearly inside the tech pack.

What Are the Core Parts of a Professional Tech Pack?

A complete tech pack removes uncertainty. It answers questions before they are asked and prevents factories from making assumptions. Missing information often leads to incorrect samples, delays, and unnecessary revisions.

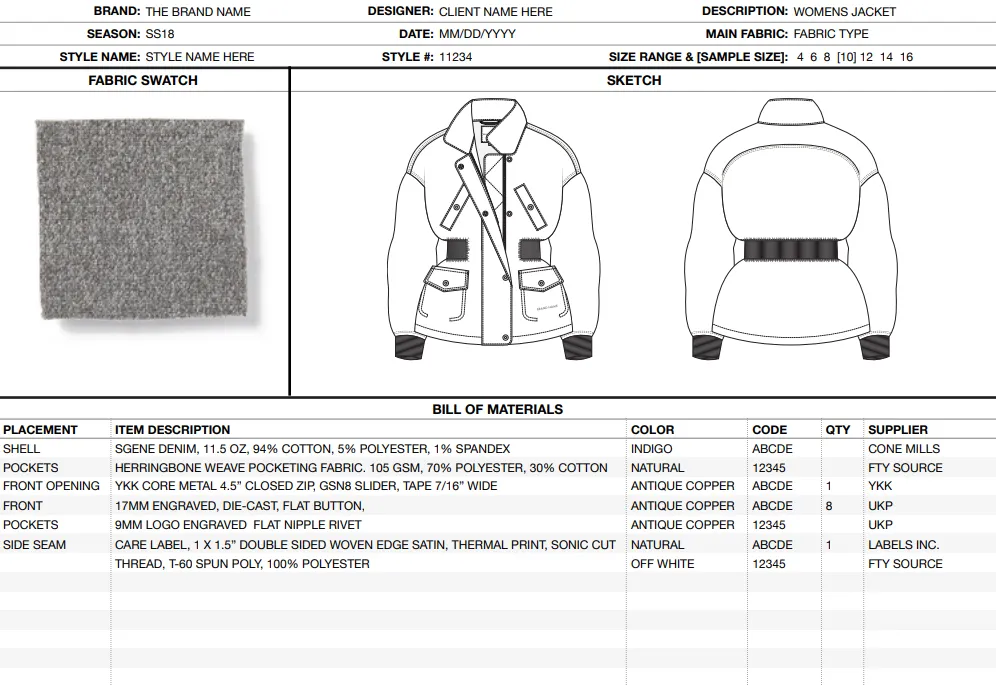

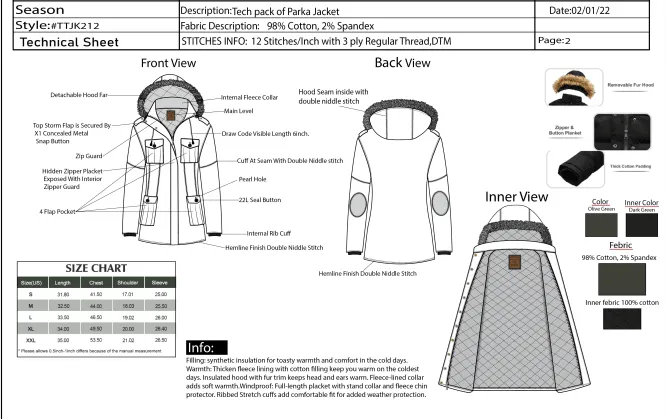

A professional tech pack normally includes:

- Technical flat drawings

- A full bill of materials (BOM)

- Construction and sewing instructions

- A measurement specification sheet

Each part plays a unique role in guiding production. Example: “Inspired by military jackets” becomes:

- Patch pockets with flaps

- Matte metal snap buttons

- Heavy twill fabric, 280–300 GSM

- Reinforced shoulder seams

Why are technical flat drawings essential?

Technical flats show the garment exactly as it should be made. Unlike artistic sketches, they focus on structure, not mood. Flats display seam lines, stitch paths, pocket placement, trims, and proportions in a clean, simple format. These drawings should be to scale, usually in black and white, and include callouts for important details. They become the visual reference that all other instructions rely on. Example: A flat drawing includes:

- Front and back views

- Stitch lines on seams

- Pocket placement with measurements

- Button and zipper locations

How detailed should the Bill of Materials be?

Your BOM should list every single component needed to make the garment. Vague descriptions create risk. Instead of general terms, include fiber content, fabric weight, finish, color, size, and brand names when applicable. For example, hardware, labels, threads, and trims should all be specified clearly. When possible, include approved suppliers. This level of detail ensures consistency and avoids unwanted substitutions. Example BOM entry:

- Main fabric: 98% cotton / 2% spandex twill, 290 GSM

- Color: Navy (Pantone 19-3921)

- Thread: Polyester core-spun, Tex 40

- Zipper: Nylon coil zipper, 18 cm, black

How Do You Build Accurate Garment Measurements?

The measurement section defines fit. It is one of the most sensitive and technical parts of the tech pack. Small mistakes here can result in poor sizing across an entire production run. Begin with a base size and define each measurement using standard points of measurement (POM). Measurements should be clear, repeatable, and labeled correctly. Always include tolerances so factories understand what variation is acceptable. Consistency is more important than complexity. Clear rules lead to predictable results.

Which measurements matter the most?

While every garment is different, most tech packs include:

- Chest or bust width

- Waist width

- Hip width

- Total garment length

- Sleeve length

Always state whether measurements are taken flat or around the body. This avoids confusion during sampling and inspection. Example (men’s shirt, size M):

- Chest width: 56 cm (measured 2.5 cm below armhole)

- Shoulder width: 46 cm

- Sleeve length: 63 cm

- Garment length: 74 cm

How do grading rules support fit consistency?

Grading rules explain how measurements change between sizes. Without grading instructions, factories may guess, which often leads to distorted proportions. Create a simple chart showing how each measurement increases or decreases from size to size. Controlled grading keeps the garment balanced and wearable across the full size range.

Example grading rule:

- Chest: +4 cm per size

- Waist: +4 cm per size

- Sleeve length: +1 cm per size

How Do You Define Construction and Quality Standards?

Construction notes turn your tech pack into a working manual. They explain not just what the garment looks like, but how it should be assembled and finished. Specify stitch types, stitch density, seam construction, reinforcement areas, and thread usage. These details affect durability, appearance, and comfort. Clear instructions reduce variation between production lines and factories. Quality standards are just as important. They set expectations before production begins.

Which construction details are often forgotten?

Many brands overlook key technical points, such as:

- Stitches per inch (SPI)

- Internal seam finishing

- Reinforcement at stress points

- Thread type and thickness

- Pressing and final finishing requirements

Including these details improves both performance and longevity. Examples of commonly missed details:

- Stitch density: 10–12 SPI on main seams

- Seam finish: Overlock + topstitch

- Reinforcement: Bar-tacks at pocket corners

- Pressing: Final steam press before packing

How do you make quality standards measurable?

Quality rules should be objective, not vague. Instead of saying “high quality,” define performance criteria. This may include fabric testing standards, color fastness levels, or acceptable measurement tolerances. Clear benchmarks help factories self-check their work and give inspectors clear pass-or-fail criteria. This reduces disputes and improves consistency. Example quality benchmarks:

- Measurement tolerance: ±0.5 cm

- No skipped stitches longer than 1 cm

- Fabric color change after wash ≤ Grade 4

- No visible oil stains or loose threads

Conclusion / Final Words

Creating a professional tech pack is a disciplined process that turns ideas into clear instructions. By defining your concept, documenting materials, setting accurate measurements, and detailing construction and quality standards, you give your factory everything it needs to succeed. A strong tech pack protects your vision. It saves time, reduces errors, and increases the chance that the final product looks and fits exactly the way you imagined. In modern apparel manufacturing, it is not optional it is essential.

Contact Information – Mekong Garment Factory:

- Vietnam Phone: +84 947 729 829

- WeChat: +84 947 729 829

- WhatsApp: +84 947 729 829

- Email: hanh@kimmy.vn