In the garment industry, chemicals are used in many stages — from fabric treatment to dyeing and finishing. While they are essential for production, they can also be extremely dangerous if not handled correctly. Improper chemical transfer may lead to leaks, fires, or serious health problems for workers. That’s why every factory must follow a clear, safe, and standardized chemical transfer process. This article will guide you through six essential steps to ensure both safety and efficiency in every operation.

6 Step in Safe Chemical Transfer Process

Step 1: Preparation Before Transfer

Before any chemical transfer begins, preparation is the most important step. It ensures that all tools, labels, and containers are ready and safe to use. A small mistake during preparation can lead to big risks later on. Workers must check equipment carefully, wear proper protective gear, and confirm that all containers are in good condition. With good preparation, accidents can be prevented before they happen.

Preparation is the foundation of safety. A well-prepared setup reduces risks, prevents accidents, and ensures that the entire process runs smoothly. Before beginning the transfer, workers should:

- Check chemical labels: Make sure all labels are intact, legible, and correctly identify the chemical name and hazard type. Never use unmarked containers.

- Inspect all containers: Confirm there are no leaks, cracks, dents, or corrosion. Containers should be clean, dry, and suitable for the substance.

- Wear appropriate PPE (Personal Protective Equipment): Include gloves, chemical-resistant aprons, safety goggles, and respiratory masks suitable for the substance.

- Prepare emergency equipment: Keep fire extinguishers, absorbent pads, and chemical spill kits within reach.

Proper preparation not only ensures

Step 2: Location and Conditions for Transfer

The area where the chemical transfer takes place must always be safe and well-controlled. Choosing the right environment reduces the chance of spills, fires, or exposure. It should be open, well-ventilated, and far away from heat or flames. All transfer zones must be marked clearly with warning signs and kept free of clutter. A clean, organized workspace protects both workers and the entire production line.

The environment where the chemical transfer takes place must meet strict safety conditions. Never perform the transfer in random areas or near production lines.

- Select a well-ventilated location — ideally an isolated chemical handling room equipped with exhaust fans or air filtration systems.

- Avoid ignition sources such as open flames, sparks, or hot surfaces.

- Mark the area clearly with visible hazard signs (“Chemical Transfer Zone,” “No Smoking,” etc.).

- Keep the space uncluttered and dry, ensuring easy movement and accessibility to emergency exits.

A well-controlled workspace is the key to minimizing potential hazards.

Step 3: Requirements During Transfer

During the transfer process, every movement matters. Even a small splash or imbalance can cause a dangerous reaction. That’s why workers must handle each step slowly and carefully, following the proper procedure. Containers should be stable, tools must be clean and suitable for chemicals, and no food or drink should ever be near the area. Staying focused helps protect everyone and keeps the process smooth from start to finish.

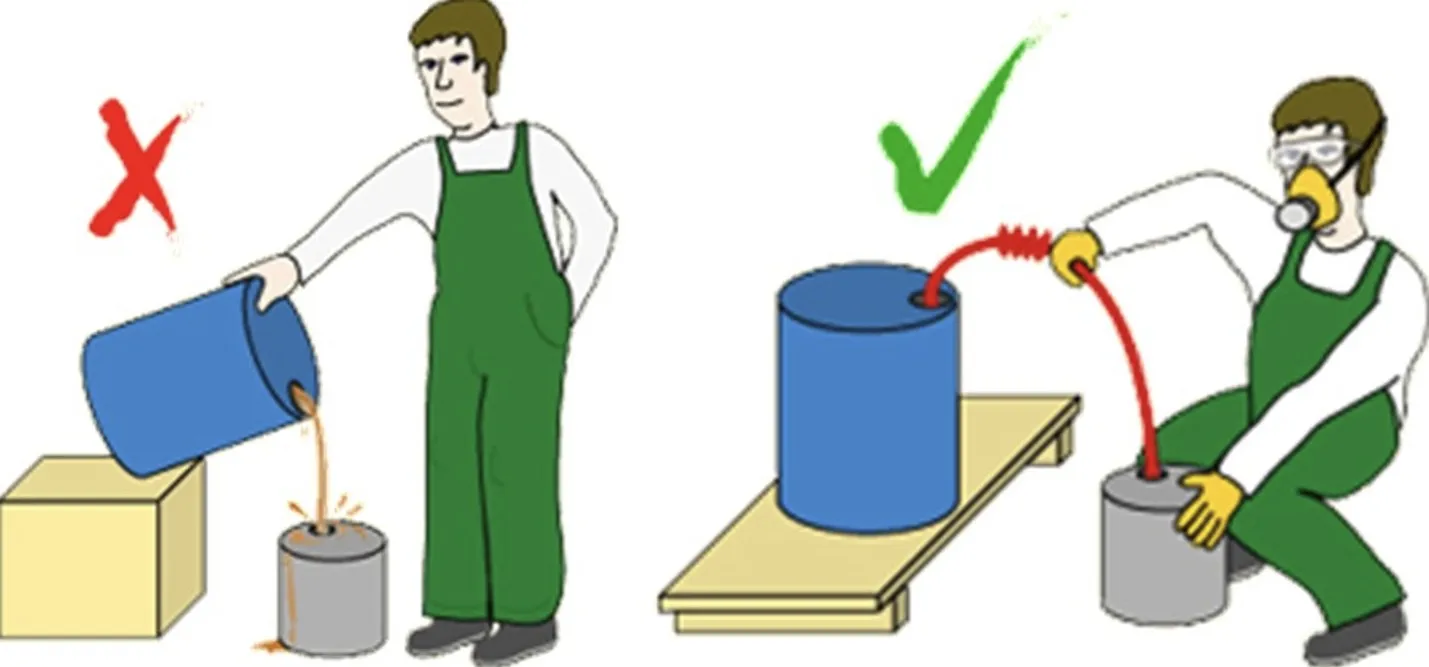

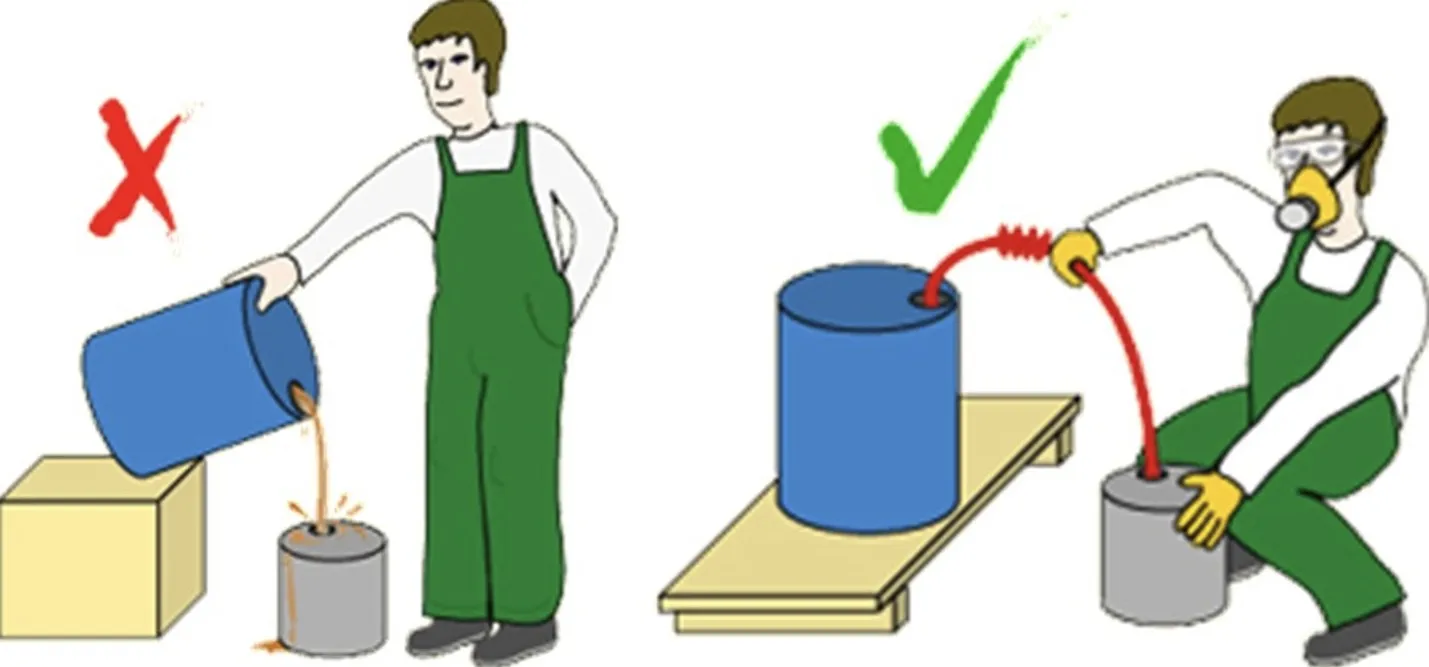

This is the most critical stage — where actual contact with chemicals occurs. Every action must be slow, steady, and precise. Follow these safety practices:

- Secure containers properly before pouring to prevent tipping or spillage.

- Use proper tools such as funnels, pumps, or transfer hoses designed for chemicals — never pour directly by hand.

- Avoid contamination by ensuring each tool is dedicated to a single type of chemical.

- Do not eat, drink, or smoke in the transfer area.

- Never use food or beverage containers (like plastic water bottles) to store chemicals.

Careful operation not only keeps workers safe but also ensures accurate measurement and quality control.

Step 4: Static Electricity and Spill Prevention

Static electricity and chemical spills are silent but serious threats in any factory. If ignored, they can cause fires, explosions, or environmental harm. Preventing these risks starts with grounding equipment and using anti-static tools. Workers must also know how to contain and clean spills quickly before they spread. Acting fast and safely can make the difference between a small problem and a major accident.

Static electricity and spills are two major causes of chemical accidents. Factories must apply proactive measures to avoid them.

- Ground all metal containers and transfer equipment before starting the process to discharge static buildup.

- Install anti-static mats or grounding wires in the transfer area.

- Place drip trays or absorbent mats under the containers to catch any accidental leaks.

In the event of a spill:

- Stop the transfer immediately.

- Isolate the spill area.

- Use appropriate neutralizing agents or absorbent materials to clean the spill.

- Dispose of waste according to the facility’s environmental management plan.

Step 5: Supporting Tools and Equipment

Having the right equipment is key to transferring chemicals safely and efficiently. Tools like pumps, hoses, and funnels must match the chemical type being used. Using the wrong tool can lead to leaks, pressure buildup, or contamination. Regular inspection and maintenance keep the system in good working order. Remember, quality tools are not just convenient—they’re a form of protection for people and property.

Using the right tools not only improves efficiency but also guarantees worker safety. All equipment must be compatible with the chemical type and approved for industrial use. Recommended equipment includes:

- Chemical-resistant funnels, hoses, and pumps, specific to acids, solvents, or flammable liquids.

- Standard-grade containers (metal, HDPE plastic, or reinforced glass) that meet safety certifications.

- Monitoring devices such as flow meters or pressure gauges to track transfer progress.

- Secondary containment systems for large-volume transfers.

Regularly inspect and maintain all equipment to prevent deterioration or malfunction.

Step 6: After-Transfer Safety and Clean-Up

Even after the transfer is complete, the job is not finished yet. This stage focuses on cleaning, sealing, and recording to prevent future risks. Containers should be tightly closed, clearly labeled, and stored in their proper locations. Workers must also clean up any remaining residues and log all details in the safety record. These small habits create long-term safety and traceability across the entire chemical management system.

Safety doesn’t end when the liquid stops flowing. Post-transfer actions are crucial for long-term safety and record-keeping. After completing the transfer:

- Seal and tighten all container lids immediately.

- Label containers clearly with the chemical name, hazard classification, transfer date, and responsible personnel.

- Clean all tools and the surrounding area using appropriate neutralizing or cleaning agents.

- Record the activity in the chemical transfer logbook, including date, time, type of chemical, and quantity.

- Report any irregularities to the safety officer for follow-up.

The chemical transfer process not only helps ensure labor safety but also prevents the risk of fire/explosion and environmental pollution. Every individual involved must be trained periodically, understand the regulations, and always follow the instructions correctly. Safe chemical transfer is the foundation for a safe, sustainable working environment.

Final Word / Conclusion

Safe chemical transfer is more than a rule — it’s a shared responsibility among all factory members. Every worker, from line operators to supervisors, plays a part in protecting lives and the environment. Following the six-step process builds a culture of safety that benefits everyone. When safety becomes a habit, productivity and trust naturally grow stronger. Together, we can make garment production safer, cleaner, and more sustainable.