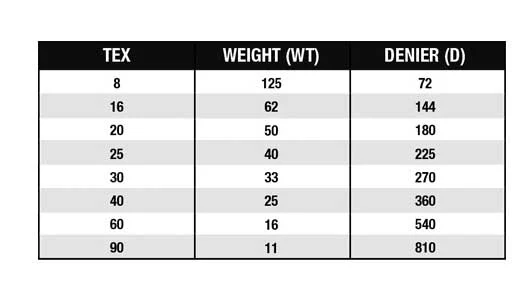

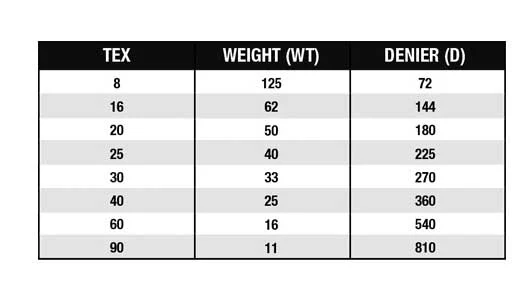

If you’ve ever seen Tex 27, Tex 40, or Tex 60 on a thread cone, that number is not a “mystery thickness code.” It’s a simple weight-per-length system. But here’s the catch: Tex measures mass, not diameter, so “thicker” is usually true but not guaranteed.

=> Related Article: Sewing Thread Specifications in the Garment Industry

What is Tex, in plain words?

Tex is a thread size system based on weight. It tells you how many grams 1,000 meters of thread weighs. So:

- Tex 25 means 1,000 m weighs 25 g

- Tex 60 means 1,000 m weighs 60 g

This is why Tex is called a direct numbering system: higher number = heavier thread per same length.

The Exact Definition (the “math truth”)

Tex is a form of linear density (mass per unit length). Standards describe linear density as the mass per unit length of a yarn, expressed in tex (and related units). The two formulas you’ll actually use:

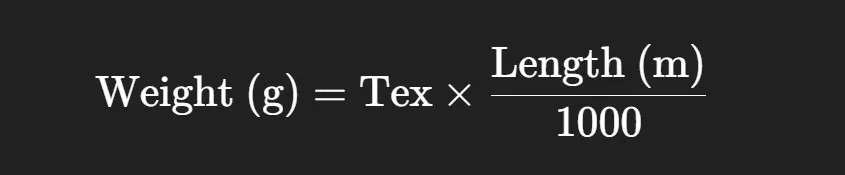

A) If you know Tex and length

Weight (g) = Tex × Length (m) ÷ 1,000

Example: Tex 30, length 250 m. Weight = 30 × 250 / 1000 = 7.5 g

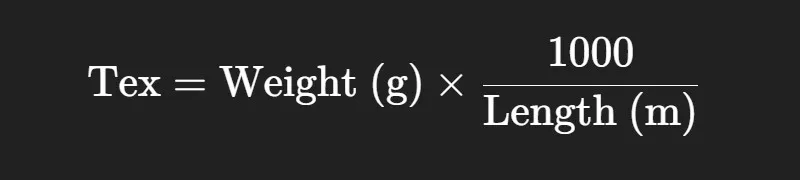

B) If you know weight and length

Tex = Weight (g) × 1,000 ÷ Length (m)

How Tex is Used in Real Factories

| Use case | Typical “feel” | Common Tex range |

|---|---|---|

| Light fabric seams, neat stitch | fine | Tex 18–24 |

| General garment seams | medium | Tex 27–40 |

| Heavy seams, workwear | thick/strong | Tex 45–70 |

| Decorative topstitch | very bold | Tex 80+ |

Sourcing and Specs

When you write thread in a BOM or tech pack, Tex helps you avoid vague words like “medium thread.” Example spec lines:

- Sewing thread: Poly core-spun, Tex 40

- Topstitch thread: Poly, Tex 60

- Heavy duty seams: Bonded nylon, Tex 70

Many thread companies prefer Tex because it’s consistent and easy to communicate across factories and countries.

Matching Thread Size to Use (practical ranges)

This is a rule-of-thumb map (always test, but it’s a good start):

- Tex 18–25: fine seams, light fabrics

- Tex 25–40: general garment seams (common “workhorse” zone)

- Tex 40+: heavier seams, stronger visual stitch, workwear

- Tex 80+: bold topstitch / very heavy duty

Even retail thread suppliers describe similar “light/medium/heavy” Tex ranges.

Sewing setup (where Tex really matters)

If you increase Tex and change nothing else, you can get:

- skipped stitches

- puckering

- frequent breaks

- ugly loops / tension issues

Higher Tex usually needs:

- a bigger needle

- adjusted tension

- possibly different stitch density (SPI)

Tex doesn’t “guarantee strength,” either. Strength depends on fiber and construction, not just size.

Common mistakes (and how to avoid them)

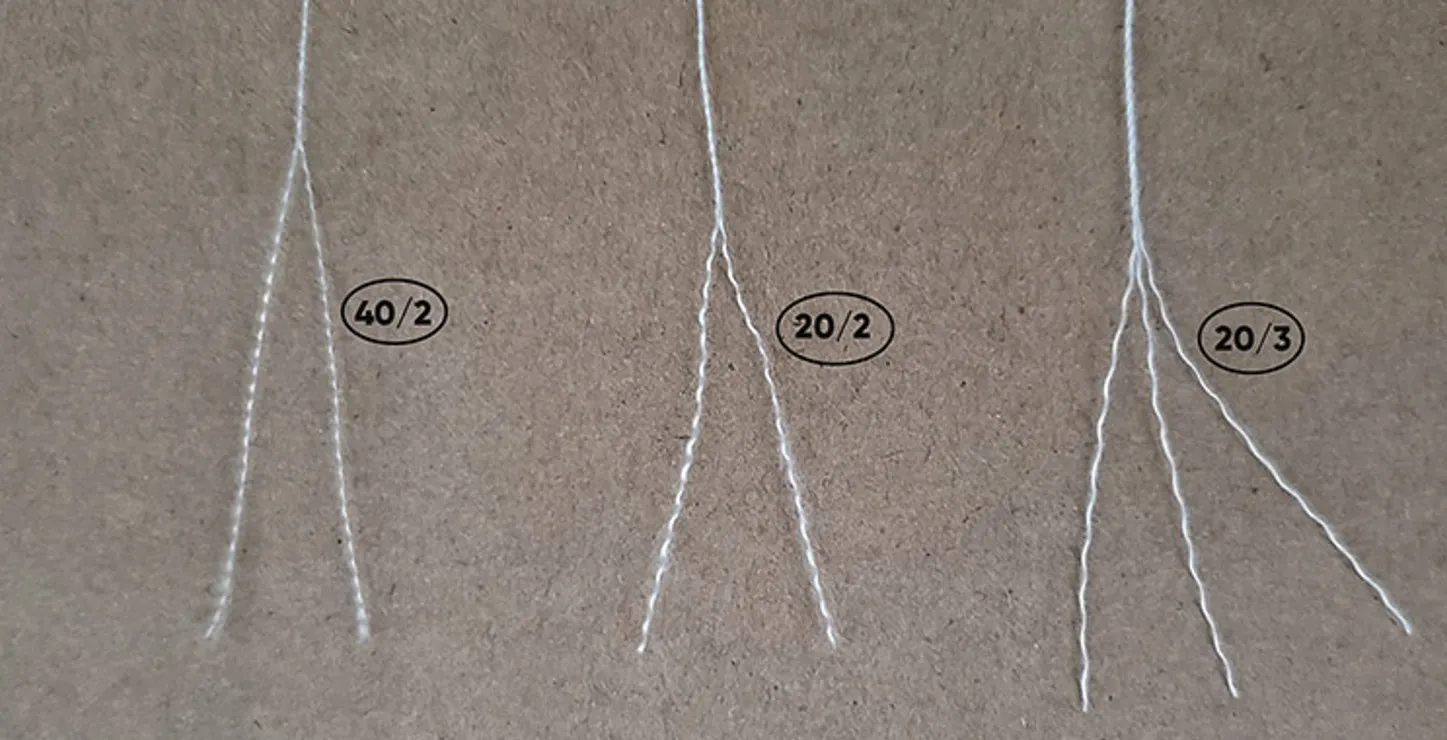

Mistake 1: “Same Tex = same thickness look”

Not always. A cotton spun thread and a polyester filament thread can behave and look different at similar Tex.

=> Always request: fiber type, construction (spun/filament/core-spun), finish (bonded or not)

Mistake 2: Choosing Tex by “strength” only

Tex is size. Strength also depends on: material (nylon vs poly), tenacity, bonding/finish, seam design

=> Fix Mistake 2: For critical products (bags, workwear, load-bearing seams), ask for breaking strength data and run seam tests.

Mistake 3: Ignoring machine limits

Some home or light industrial setups struggle with heavy Tex threads.

=> Fix Mistake 3: Choose thread size based on what your machine + needle + fabric can run cleanly, then scale up only if needed.

Conclusion: The smart way to use Tex

Tex is the best “common language” for thread size because it’s direct and easy: grams per 1,000 meters. But if you treat Tex as “diameter,” you’ll get burned because construction and fiber can change the look and sewing behavior. Use Tex as your anchor, then lock the outcome with construction details and stitch-out approval. That’s how brand owners keep quality consistent across suppliers and seasons.