OEM/FOB in the Garment Industry: What It Really Means

Garment orders mean you supply design while the manufacturer handles sourcing, production and delivery up to ship loading, and under FOB responsibility transfers to you when goods are loaded. This gives your brand agility and lower upfront capital, but be aware of risks like late materials, quality failures and costly disputes. With clear specs, tight communication and solid quality checks you can secure faster turnarounds and the higher margins and stability that OEM/FOB enables.

What OEM / FOB in Garment Manufacturing?

In the garment industry context, when people say “OEM/FOB order”, they typically mean: the brand provides the design (and often technical specifications) and the manufacturer takes on sourcing materials, manufacturing, finishing and delivering the goods to the agreed port (i.e., “up to ship loading”).

OEM Means:

OEM (Original Equipment Manufacturing) refers to a production model where a manufacturer builds products based on the design, specification and branding of another company (the “brand” or ordering party).

FOB Means:

FOB (Free On Board) is an international commercial term (Incoterm) referring to the point at which responsibility transfers from the seller (manufacturer) to the buyer; typically, the seller supplies goods and loads them on board the ship at the named port of shipment and clears them for export.

How the OEM/FOB Works in Garment Industry

An OEM/FOB order follows a structured process that makes sure every step is clear for both the brand and the manufacturer. This workflow is important because it helps control quality, manage cost, and prevent delays. Each stage from design to shipment includes important checkpoints that keep the final product aligned with the customer’s expectations. Brands benefit from this clarity because they know exactly when to approve materials, samples, and production. Manufacturers benefit because the system avoids confusion and builds trust. Here’s a typical workflow for an OEM/FOB garment order:

- Design & Specification Provided: The brand/ordering party supplies the garment design (sketches, tech pack, sizing, colors), possibly with requirement for materials, trims and quality levels.

- Material Sourcing: The manufacturer sources fabric, trims, accessories, and other input materials. Depending on the contract, the brand may specify approved suppliers or allow the manufacturer to source freely.

- Sample / Prototype Phase: The manufacturer produces a sample garment for approval – fitting, workmanship, color, labeling, finishing, etc.

- Mass Production: Once the sample is approved, full production runs begin: cutting, sewing, finishing, pressing, packaging.

- Quality Control & Inspection: Manufacturer undertakes QC to ensure units conform to specification (e.g., size tolerances, seam strength, color fastness, accessory attachments).

- Shipment to Port (FOB Stage): The manufacturer arranges export‐clearance, transports finished goods to the named loading port, loads them onto the vessel. From this point responsibility (cost, risk) typically passes to the buyer.

- Buyer Takes Over Logistics: The buyer arranges sea freight, insurance, destination port clearance, inland shipping and final delivery.

Key Variants of the OEM/FOB Model

Not all OEM/FOB orders look the same. Some give full sourcing power to the manufacturer, while others require the manufacturer to follow a strict list of approved suppliers. These different levels change how much control each side has and how much margin the manufacturer can earn. Brands that want stable quality may prefer designated suppliers, while manufacturers with strong sourcing networks prefer more freedom. By understanding these levels, both sides can choose the model that fits their goals.

- FOB Level I: The manufacturer purchases materials from suppliers designated by the buyer (brand). The manufacturer handles production and shipping but uses buyer‐specified supply chain.

- FOB Level II: The manufacturer has full autonomy in sourcing materials, managing production and shipping to the agreed port. The brand focuses mainly on design/spec and final product. This gives the manufacturer more responsibility and also higher margin potential.

- OEM/FOB “Just design” and let manufacturer run process: In many cases the brand simply provides the design and accepts that the manufacturer manages material sourcing, production, and shipment up to port. This is often called an “OEM/FOB order”.

Why These Terms Matter / The Value Chain Angle

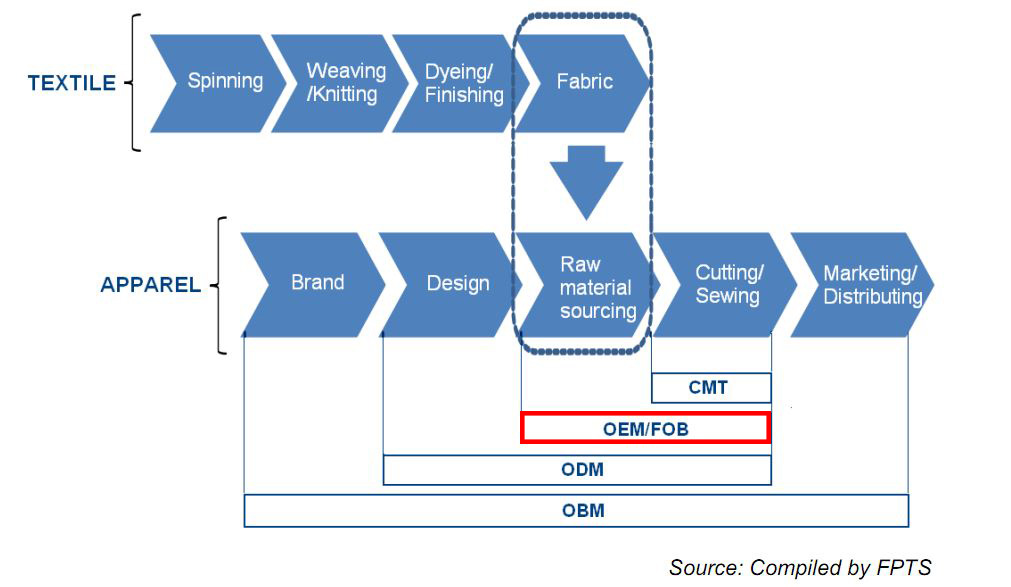

- The garment industry commonly divides production models into tiers based on value added: for example CMT (Cut-Make-Trim), OEM/FOB, ODM (Original Design Manufacturing), and OBM (Original Brand Manufacturing).

- CMT represents the lowest value – manufacturer simply performs production steps (cut, sew, trim) using materials supplied by the buyer. OEM/FOB sits above that because the manufacturer takes more responsibility (including sourcing materials) adding more value and control.

- As manufacturers move up the chain (from CMT to OEM/FOB to ODM/OBM), they capture a higher margin & greater involvement in the value chain.

Benefits & Risks

Benefits for the brand/ordering party:

For brands, OEM/FOB creates a strategic advantage because it shifts the heavy workload of production and sourcing to the manufacturer. This allows the brand to spend more time improving designs, expanding markets, and building customer loyalty. In fast-fashion, athleisure, and medical apparel, quick turnaround matters which makes OEM/FOB a natural choice. It also reduces financial pressure because the brand does not need to purchase large volumes of raw materials or maintain a production facility. Overall, OEM/FOB helps brands grow with less risk and greater flexibility.

- Less capital tied up in materials procurement and inventory. Since the manufacturer handles sourcing, the brand can focus on design, marketing and brand building.

- Reduced management overhead in sourcing fabrics/trims and handling logistics up to the port.

- Potentially faster market entry if the manufacturer already has sourcing network and production capability.

Benefits for the manufacturer:

Manufacturers gain significant opportunities when they upgrade from basic CMT to OEM/FOB. They begin controlling more parts of the value chain, including sourcing, costing, lead-time planning, and quality management. Although responsibility increases, so does profitability — because more services mean higher margins. At the same time, OEM/FOB builds stronger relationships with brands, making orders more stable and predictable. This model also encourages factories to improve internal systems, which helps attract bigger clients.

- Higher margin compared to simple CMT because they control more of the value chain (material purchasing, production management, shipping) which offers margin opportunities.

- Improved competitiveness brands increasingly prefer partners who can offer more integrated services (material sourcing + production + shipping).

- Opportunity to build stronger sourcing networks, better economies of scale in materials purchasing.

Risks / challenges:

While OEM/FOB offers attractive benefits, it comes with responsibilities that must be managed carefully. Both the brand and manufacturer face risks in sourcing, shipments, and product quality. If material arrives late or fails quality tests, the entire production schedule can collapse. In addition, misunderstandings about FOB responsibilities can create costly disputes. A successful OEM/FOB partnership requires trust, transparency, and very clear communication.

- Material sourcing risk: If the manufacturer is responsible for sourcing, they must ensure quality, timely delivery, cost control, compliance (e.g., environmental/CSR) any failure impacts schedule, cost and quality.

- Responsibility transfer: Under FOB, once goods are loaded, risk shifts to buyer; but if the manufacturer fails to deliver or there are defective goods, contractual clarity is essential.

- Brand’s design and IP: In OEM model, brand must ensure protection of designs, trademarks, specifications; mis‐use by manufacturer or sub‐supplier could occur.

- Minimum order quantities (MOQs) may still be high because manufacturer must commit to materials and production setup.

Conclusion / Final Words

OEM/FOB has become one of the most important working models in today’s garment industry because it balances responsibility between brands and manufacturers in a simple, practical way. When both sides understand their roles clearly, the entire process — from material sourcing to ship loading — becomes faster, cleaner, and more predictable. Brands gain more freedom to focus on design and market growth, while manufacturers can earn higher value by managing more of the production chain. With strong communication and well-planned quality control, OEM/FOB can build long-term partnerships that benefit everyone involved. As global fashion continues to move toward speed, flexibility, and reliability, OEM/FOB will remain a key model shaping how apparel is made and delivered around the world.

FAQs About OEM/FOB in the Garment Industry

In Short, Under an OEM/FOB arrangement, what specific responsibilities fall to the manufacturer?

The manufacturer handles material sourcing (unless restricted by the buyer), cost negotiation with suppliers, production planning, cut-make-trim (CMT) activities, quality control, packing to buyer specifications, export documentation, customs clearance and physically loading containers onto the vessel at the named port. Mekong Garment Vietnam often also coordinates samples, fit approvals and pre-shipment inspections when agreed in the contract.

In Short, What does OEM/FOB mean in the garment industry

OEM (Original Equipment Manufacturing) means the manufacturer produces garments to a brand’s design, specs and branding. FOB (Free On Board) is an Incoterm where the seller (manufacturer) is responsible for producing, packing, clearing exports and loading the goods onto the ship at the named port; liability and freight cost transfer to the buyer once cargo is on board.

What does the brand/ordering party need to provide and manage in an OEM/FOB order?

The brand supplies technical files (specs, patterns, grading, bill of materials), artwork and labeling instructions, sampling and approval timelines, packaging requirements, and the shipping instructions including nominated port and preferred carrier if applicable. The buyer arranges and pays for ocean freight, insurance beyond FOB point, import clearance and inland delivery at destination. Brands may also specify approved suppliers or quality standards that the factory must follow.

What does the brand/ordering party need to provide and manage in an OEM/FOB order?

The brand supplies technical files (specs, patterns, grading, bill of materials), artwork and labeling instructions, sampling and approval timelines, packaging requirements, and the shipping instructions including nominated port and preferred carrier if applicable. The buyer arranges and pays for ocean freight, insurance beyond FOB point, import clearance and inland delivery at destination. Brands may also specify approved suppliers or quality standards that the factory must follow.

What are the typical steps in an OEM/FOB workflow from design to ship loading?

Typical steps: 1) Technical packet and design handover; 2) Sample development (proto, fit, pre-production sample) and approvals; 3) Material sourcing and approval; 4) Production planning and cutting; 5) Sewing and finishing; 6) In-line and final quality inspections; 7) Packing, labeling and marking per buyer specs; 8) Export documentation and customs clearance; 9) Loading on board at the named port. Each stage requires clear sign-offs to avoid delays and disputes.

What variants of OEM/FOB exist and how do they change control, cost and manufacturer margin?

Variants range from brand-controlled sourcing (manufacturer must buy from approved suppliers) to manufacturer-controlled sourcing (full sourcing freedom). Other variants include partial FOB where the brand supplies key materials (e.g., fabrics) and the factory provides manufacturing and export services. Greater sourcing freedom usually increases manufacturer margin and shortens lead times, while brand-controlled sourcing provides more consistency and lower material-risk for the brand but can reduce factory margin and speed.