Understanding how much cotton a knit fabric truly contains is one of the simplest yet most important steps in choosing quality material. The cotton ratio determines not only the softness and breathability of the fabric, but also its strength, elasticity, and comfort during wear. Many fabrics today are blended with synthetic fibers, which can make them look and feel similar to pure cotton yet perform very differently over time.

That’s why learning to recognize real cotton content through practical tests is a valuable skill for designers, buyers, and even everyday consumers. In this guide, you’ll discover clear and reliable ways to identify cotton-rich fabric from subtle visual signs to hands-on methods like water absorption and burn testing so that every choice you make is backed by knowledge, not guesswork.

6 ways to know How Much Cotton Is in a Fabric

Visual Inspection

Seeing is your first, fastest test. Look at the surface under good light and, if possible, through a phone macro lens. High-cotton knits usually look slightly matte, show tiny fuzz, and the stitches are not perfectly uniform. Blends with more polyester look smoother, more even, and may have a gentle sheen. Also check color depth: cotton often holds soft, natural tones, while synthetics can appear a bit “glassy.” These small visual clues help you estimate the cotton ratio before any other test. Start by looking at the fabric closely:

- Fabrics with a high cotton content tend to have a slightly matte surface, may show tiny fuzz or little fibres, and are not overly shiny.

- Fabrics with more synthetic (polyester/PE) content often have a smoother, shinier surface, and the fibre structure may appear more uniform. If the fabric feels cool to the touch, has a natural matte look and little sheen, it’s likely to have a higher cotton ratio.

Water-Absorption Test

Water tells the truth about fiber. Place one clean drop on a flat area of the fabric and watch closely for 5–10 seconds. If it spreads quickly and sinks in, the fabric likely has a high cotton percentage. If it beads up or takes longer to penetrate, there’s probably more synthetic content. Try two or three drops in different spots to avoid coating effects from finishing chemicals. This quick test is low-cost, repeatable, and great for routine screening. This is a simple and effective test for cotton content:

- Drop a small amount of water onto the fabric surface. If the fabric is high in cotton, the water will soak in quickly and spread out over a broader area.

- In contrast, if the fabric contains more synthetic fibres, the water will absorb slowly, or may stay as droplets for a longer time, and the wet area stays small. So, the faster and more widely the water spreads, the higher the likely cotton content.

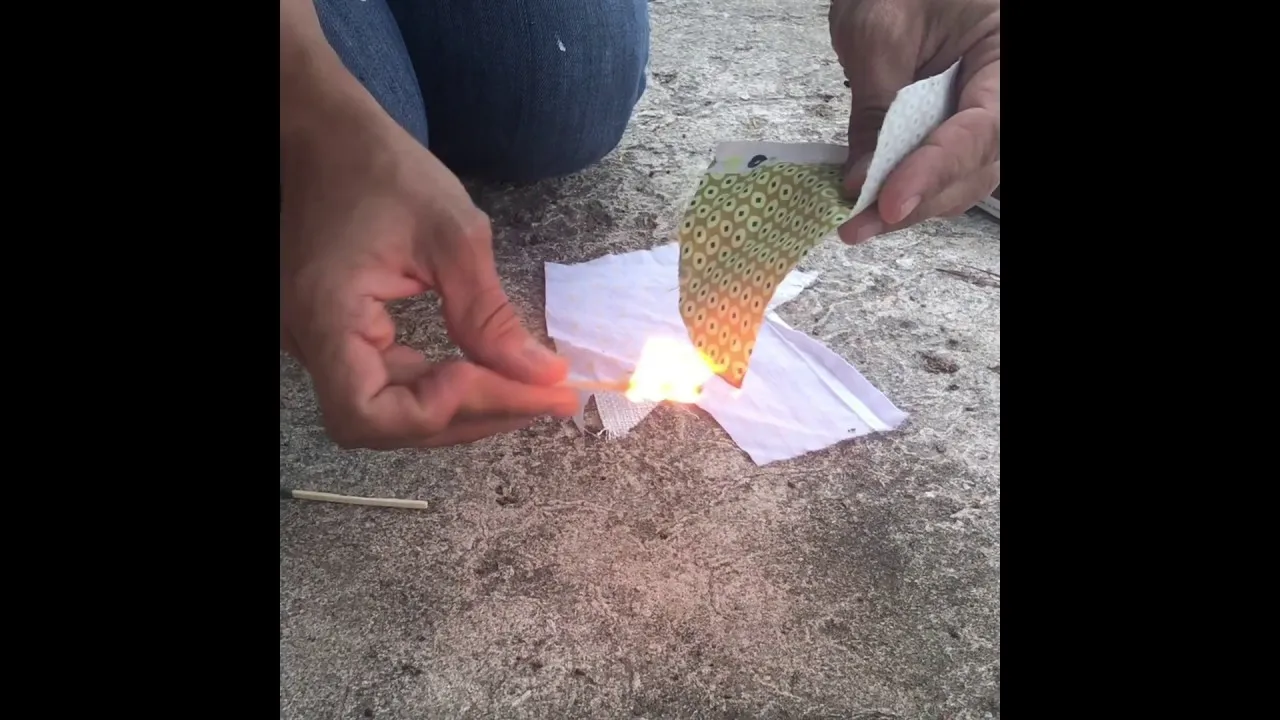

Burn Test (Use with Care)

This test is more technical, so safety comes first. Use a tiny swatch, metal tweezers, and do it in a ventilated area with water nearby. Cotton catches easily, smells like burning paper, and leaves soft grey ash that crumbles. Synthetics melt, may drip, smell chemical, and cool into hard beads. Mixed fabrics show mixed signs, so repeat if results are unclear. Use the burn test to confirm what your eyes and water test already suggest.

This test is more accurate but also requires care and appropriate safety measures.

- Cut a small scrap of the fabric (in a safe, well-ventilated environment), and ignite it briefly. If it’s nearly pure cotton: the flame burns easily, gives a smell like burning paper, the ash is fine grey powder that easily crushes.

- If the fabric has more synthetic content: the flame may burn slower or irregularly, produce a plastic or chemical smell, the residue may be in hard lumps or melted clumps rather than fine ash.

- Important: This method is more technical and has safety risks; only do it if you are able and it’s safe to do so.

| Trait | 100% Cotton (natural fiber) | Polyester or synthetic fibers |

|---|---|---|

| Flame | Burns quickly and evenly | Burns more slowly; may melt |

| Smell | Smells like burning paper or hair | Smells like burning plastic or rubber |

| Ash / residue | Fine ash, light grey, easy to crumble | Hard, sticky lumps, often plastic‐like |

Label & Supplier Information

Labels and supplier data save time and reduce guesswork. Always read the fiber breakdown (for example, 100% cotton or 65/35 cotton-poly) and ask for a spec sheet if you buy in volume. Reputable suppliers can share test reports, finishing details, and QC notes that affect feel and performance. Request swatches for hands-on checks and keep samples labeled for future comparison. Cross-check what you read with simple field tests to ensure accuracy. Clear documentation plus simple testing gives you the best decisions.

- Check the fabric label or ask the supplier for the blend percentage (e.g., “100% cotton”, “65% cotton / 35% polyester”). Many fabrics will list this.

- Be aware: some fabrics labelled “100% cotton” may still be blends or lower-grade cotton, so using the tests above can help confirm.

- When buying in bulk (for garments, uniforms, etc.), ask for the exact ratio and possibly a sample you can test.

Measure GSM – Weight of Fabric per m²

GSM (grams per square metre) is the unit used to measure the weight and thickness of fabric. Although GSM itself does not reveal the exact fiber composition, fabrics made largely of cotton typically fall within a certain GSM range. Measuring GSM helps assess how heavy or thick the fabric is, and indirectly gives a clue about its quality and suitability for different uses. For example: if a piece of fabric is 2 m × 1 m and weighs 500 g, then GSM = 500 / (2 × 1) = 250 gsm. Common ranges:

- Light fabrics (like voile or linen): ~50–100 gsm

- Knit cotton fabrics: ~80–150 gsm

- Denim or thick khaki: ~200–400 gsm

Tip: At the same fiber content, a higher GSM often gives a more premium feel when worn.

Use Specialised Equipment – The Most Accurate Way

When you need truly precise results such as for manufacturing, export or inspecting a large batch businesses often use specialised machines to analyse the fabric’s fiber composition. Common equipment includes:

- Moisture content testers for fibers: compare how much water different fibers hold cotton holds moisture better.

- FTIR spectrometers (Fourier-Transform Infrared Spectroscopy): analyse the chemical makeup of fibers, giving very accurate results.

Why This Matters (Comfort, Performance, and Cost)

Cotton content changes how a T-shirt feels, breathes, and ages. More cotton usually means better moisture uptake and a softer, more natural touch. More synthetics often add shape retention, faster drying, and lower cost but may trade off breathability. Your use-case decides the right mix: daily comfort vs. performance and budget. Knowing these trade-offs helps you set product standards, reduce returns, and meet customer expectations. In short, fiber knowledge pays off in both quality and profit.

Comfort and Breathability:

- Cotton is a natural, skin-friendly fiber that allows air to circulate easily.

- A higher cotton percentage means the fabric absorbs sweat quickly, keeping you cool and dry.

- Cotton-rich fabrics feel soft and gentle, making them ideal for T-shirts, underwear, and babywear.

- In contrast, synthetic-heavy fabrics may trap heat, causing discomfort or irritation in hot weather.

Durability and Shape Retention:

- Blending cotton with polyester or spandex helps fabric retain shape and elasticity after repeated washing.

- Synthetic fibers improve resistance to wrinkles and stretching, which is useful for workwear and activewear.

- However, too much synthetic content can make the fabric stiff or less breathable.

- The right balance such as 60% cotton / 40% polyester, often combines softness with longer life.

Maintenance and Care:

- 100% cotton fabric is easy to wash but may shrink slightly if not pre-treated.

- Blended fabrics dry faster and require less ironing, saving both time and energy.

- Understanding cotton ratio helps users adjust care instructions for example, lowering heat or avoiding tumble drying for high-cotton garments.

Cost and Value:

- The cotton percentage directly affects fabric price and market position.

- High-cotton fabrics often cost more due to natural fiber sourcing and softer finishing.

- Synthetic blends reduce cost but may sacrifice tactile comfort.

- Knowing fiber ratios allows both producers and buyers to balance quality and affordability effectively.

Final Word / Conclusion

In the world of textiles, understanding what your fabric is made of is more than just curiosity — it’s a foundation of quality. The cotton percentage in knit fabrics influences how garments feel, breathe, last, and even how customers experience your brand. By using simple, hands-on methods such as visual inspection, water-absorption testing, and careful burn analysis, anyone can confidently estimate a fabric’s true composition. These small steps help prevent costly mistakes, ensure consistent product standards, and guide smarter material choices.

For manufacturers and designers, accurate fiber knowledge supports better planning from selecting yarn to setting washing instructions and finishing techniques. For consumers, it’s the key to choosing clothes that truly match their comfort and lifestyle. Ultimately, a fabric’s story begins with its fiber. Knowing how much cotton it holds means understanding its character its softness, its strength, and its purpose. Whether you’re creating a new fashion line or simply choosing your next favorite T-shirt, a little fabric knowledge turns every purchase into an informed, confident choice.

FAQs About How to Know How Much Cotton Is in a Fabric

How can I tell if a fabric has a lot of cotton in it?

You can estimate cotton content by using simple methods like looking closely at the fabric under good light, doing a water absorption test, or even a burn test if done safely. High-cotton fabrics tend to look matte and absorb water quickly.

What does a visual inspection show about cotton content?

A close visual look can hint at cotton content. Fabrics with a lot of cotton usually have a slightly matte surface and tiny fuzz or fibers, while more synthetic blends often look smoother and shinier.

How does the water test work?

Place a small drop of water on the fabric. If it soaks in and spreads quickly, the fabric likely has more cotton. If the water beads or absorbs slowly, there may be more synthetic fibers.

Is the burn test reliable?

The burn test can help tell natural from synthetic fibers: natural cotton burns quickly, smells like paper, and leaves soft grey ash, while synthetics melt and smell chemical. But this test has safety risks and should only be done with proper precautions.

Can the fabric label be trusted for cotton percentage?

Yes — the fiber breakdown on a label or supplier spec sheet is a strong indicator (like “100% cotton” or “60/40 cotton-polyester”). However, testing might still be useful, because labels can be incorrect or misleading

Does fabric weight (GSM) tell me cotton content?

GSM (grams per square meter) shows how heavy the fabric is, but not the exact fiber percentage. Heavier fabrics usually feel more substantial, yet cotton content still must be estimated with other tests.

What’s the most accurate way to know cotton content?

Specialized lab equipment — like spectrometers or moisture analyzers — gives the most precise fiber composition. These tools are used for quality control or bulk fabric inspection.

Why does cotton content matter?

The amount of cotton in a fabric affects how it feels, breathes, absorbs moisture, and performs during wear. More cotton usually means softer feel and better sweat absorption, while more synthetics add shape retention and durability.