7 Step Procedure for Inspecting Empty Garment Containers Before Loading

In export import operations, a container is not only a means of transport, but also a key factor in ensuring safety, reputation, and compliance with international regulations. A container that does not meet standards may lead to losses, damage to goods, or even security breaches in the supply chain. Therefore, inspecting the container before loading is a mandatory step, helping businesses minimize mistakes, prevent fraud, and maintain trust with customers and authorities. The procedure below is designed with 7 clear and easy to apply steps, aimed at ensuring the container is always ready and secure before use.

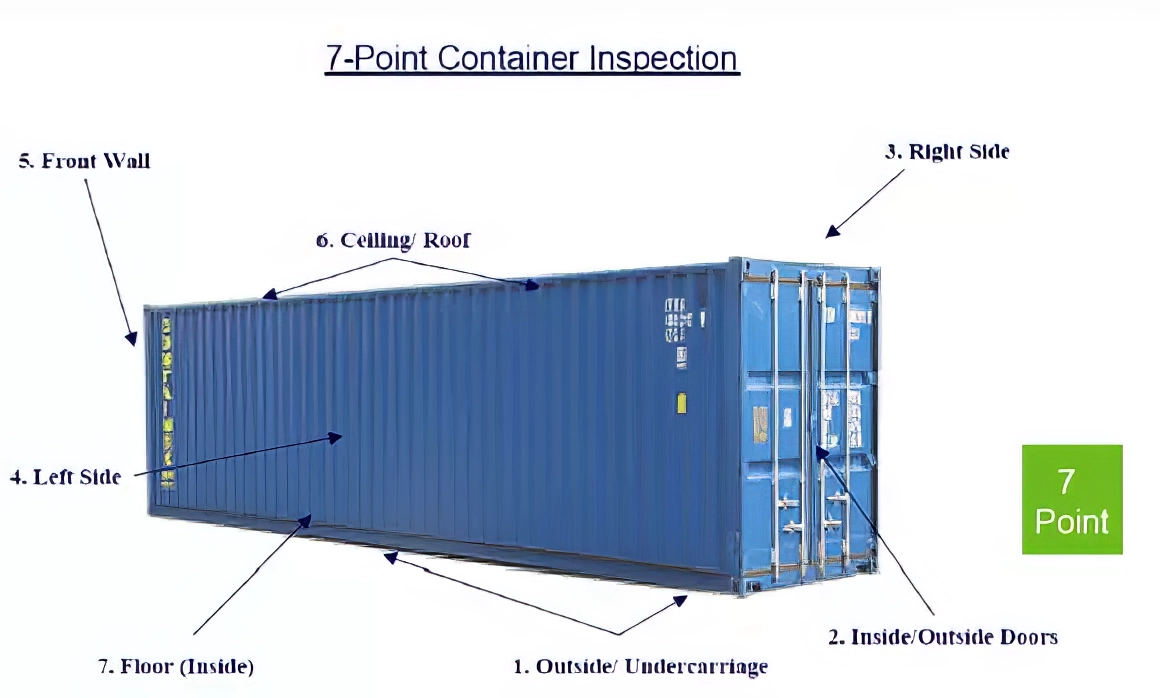

7 Step Procedure for Inspecting Empty Containers

Step 1 – Check the Doors & Door Locks

The doors are the “frontline guardians” of any shipping container. They protect the goods from theft, tampering, and weather exposure. Before a single box is loaded, it’s essential to ensure the doors and locks are working properly, securely fastened, and free from any damage or manipulation. A single loose hinge or broken seal could compromise the entire shipment. This step sets the foundation for container integrity throughout transport.

- Observe the hinges, locking bars and external latches.

- On the inside of the doors there should be no signs of drilling, forced entry or re‐welding.

- Ensure the doors open and close smoothly, with no warping or deformation.

Step 2 – Inspect the Left Side Panel

The left side panel often receives less attention, but it can be an easy target for hidden tampering. Some smugglers or unauthorized parties may cut or patch this side to conceal illicit items. By taking time to check the panel inside and out, inspectors can spot subtle signs of manipulation early. This step helps maintain full transparency and ensures the container’s body has not been secretly altered.

- Check both inside and outside surfaces.

- Look for signs of cuts, added welds, or irregular seams.

- Ensure the panel is sealed and light does not shine through.

Step 3 – Inspect the Right Side Panel

Just like the left side, the right panel can also be modified or damaged in ways that are hard to notice. Even a small dent or hidden weld could signal tampering or previous unauthorized repair. Inspecting both sides ensures the container remains structurally balanced and safe for use. Consistent checking of both panels reduces risk and promotes accountability in every shipment.

- Perform the same procedures as Step 2.

- Confirm the panel is intact and shows no signs of unauthorized repair.

Step 4 – Inspect the Container Floor

The floor is where your garments actually rest, so its condition directly affects product safety. Hidden holes, moisture damage, or contamination could ruin entire batches of goods. In some cases, smugglers may even tamper with the floor to create concealed compartments. A clean, solid, and intact floor helps keep your cargo stable and free from risk. Proper inspection here saves time, money, and reputation later.

- Examine the surface: no drill holes, gaps or tampered wood.

- Tap gently with a tool to detect hidden voids or hollows.

- Make sure the floor is clean, with no oil stains or chemical residues that could damage the goods.

Step 5 – Inspect the Roof / Ceiling

Many inspectors overlook the roof, but it’s another vulnerable point for intrusion. Holes or patches may allow water to leak in or give access from above. In rainy or humid regions, a small opening can quickly lead to mold or fabric damage. A sound, sealed roof guarantees protection for your garments throughout transit. Always make this step part of your standard inspection routine.

- From inside, ensure there is no light shining through the ceiling.

- Check for signs of welding, strange metal patches or repair work.

Step 6 – Inspect the Front Wall

Though the front wall is rarely opened, it still plays a key role in keeping the container secure. This section provides structural strength and prevents shifting of goods during movement. A cracked or tampered front wall can cause instability and compromise load safety. Taking a few minutes to examine it thoroughly can prevent expensive issues later. It’s a simple but vital step toward a safe shipment.

- Surface should be intact, with no holes or openings.

- No signs of welding or clandestine repairs should be visible.

Step 7 – Inspect the Undercarriage & Exterior

The undercarriage and outer surface are often the last things checked—but they can hide the most serious problems. Some containers are repainted to disguise old damage or illegal modifications. Others might have hidden compartments welded underneath. A careful walk-around and bottom check ensure your container is truly safe, compliant, and correctly identified. This is the final line of defense before sealing your shipment.

- Cross check the container number, logo, and markings: they should not be sanded off or repainted.

- Inspect the exterior shell: no punctures, no unusual welds.

- Check the undercarriage: no hidden cavities or spaces exploited to conceal goods.

Purpose, Scope of Application & Responsibilities

Purpose

To ensure export operations are safe and compliant, inspecting the container before loading cannot be skipped. The main objective of this procedure is to make sure the container meets security standards, prevents tampering or loss of goods, or use for hiding prohibited items.

Scope of Application

This procedure is applied uniformly for all containers before loading, whether at the factory or warehouse. This ensures consistency and uniformity in supply chain security control.

Responsibilities

In order for the inspection to be effective, there must be clear assignment of roles among the departments. The Security / QA / QC department plays the primary role in inspection and verification, while the driver or transport personnel must cooperate and support as needed.

- Security / QA / QC department: directly inspect and record results.

- Driver / transport personnel: cooperate and assist as required.

Conclusion / Final Words

Inspecting the container before loading is not just a technical procedure, but an important security shield protecting your goods, the company’s reputation, and compliance with international laws. Performing the 7 steps fully helps prevent risks, avoid loss, and ensure a transparent and safe supply chain.

Everyone involved in the process—from security, QA/QC to drivers and transport staff—must raise their awareness and responsibility to maintain seriousness and standards. Only when the container passes inspection and is confirmed on the inspection record, can loading proceed. Complying with this procedure protects the mutual interests, maintains customer trust, and contributes to building a professional, safe, and reliable business image in international trade.